Graphene medium-far infrared detector and preparing method thereof

An infrared detector and graphene technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as insufficient absorption rate, affecting graphene transport characteristics and gate electric field adjustable characteristics, etc., to achieve Effects of low gain, low cost, and high infrared light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

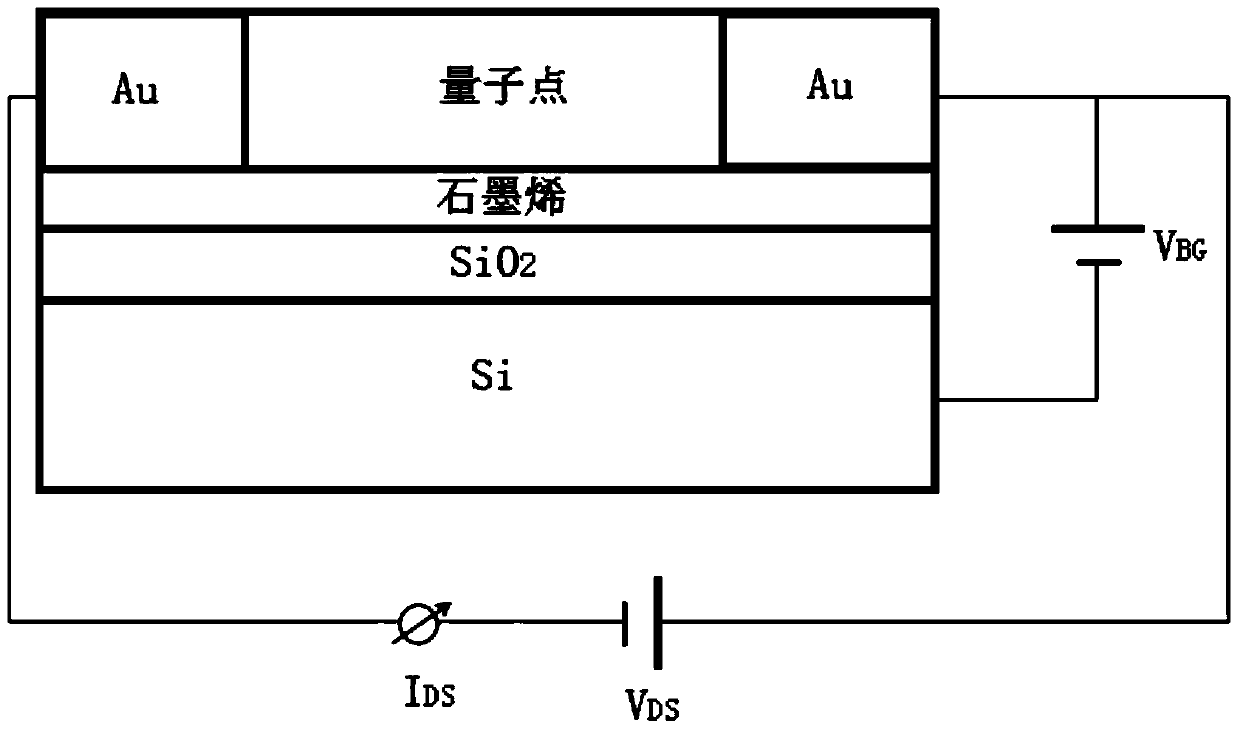

[0024] Embodiment: making InSb quantum dot graphene mid-infrared detector

[0025] When making the InSb quantum dot graphene mid-infrared detector, the present invention takes the following technical solutions:

[0026] 1. Preparation of graphene film: Obtain graphene film through standard mechanical exfoliation process, and the object of exfoliation is highly oriented pyrolytic graphite.

[0027] 2. Transferred graphene film: Transfer the exfoliated graphene to SiO2 / Si substrate with 285nm. Single-layer and double-layer graphene were found by optical microscopy, and Raman scattering spectroscopy was measured by RenishawInviaRaman microscope to determine the actual number of layers of the selected graphene sheet.

[0028] 3. Fabrication of source and drain electrodes: use PMMA as a photoresist, and manufacture drain and source electrodes of the device by electron beam lithography, and the metal of the drain and source electrodes is 5nmTi / 100nmAu.

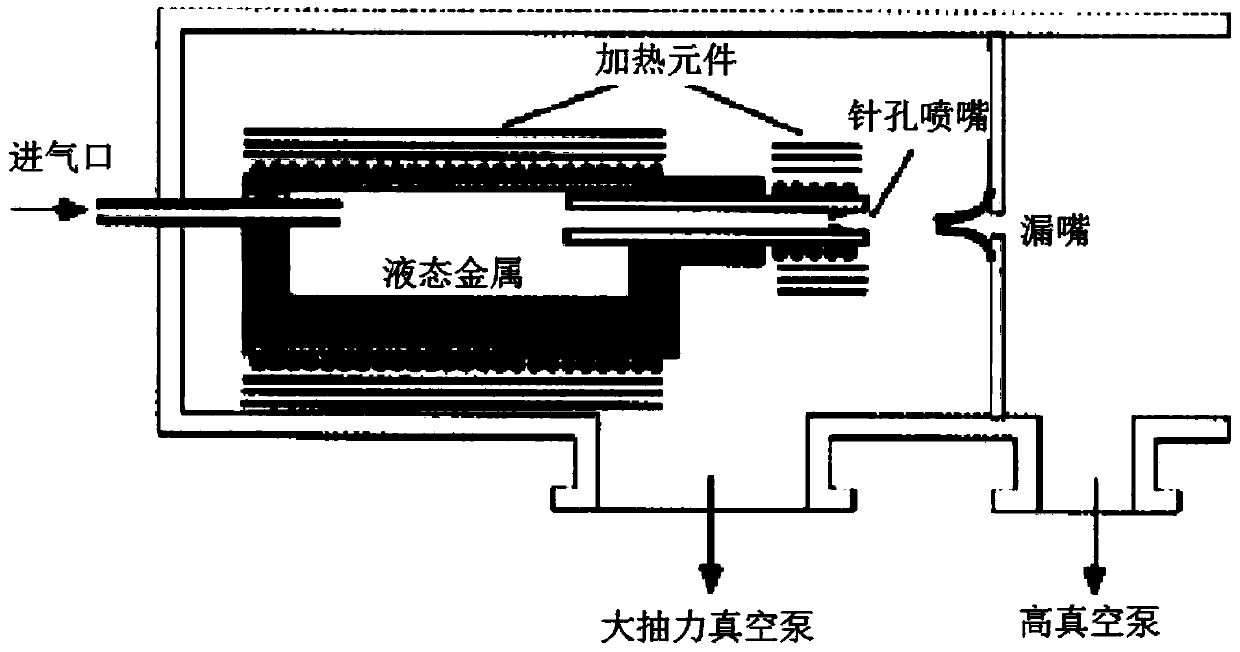

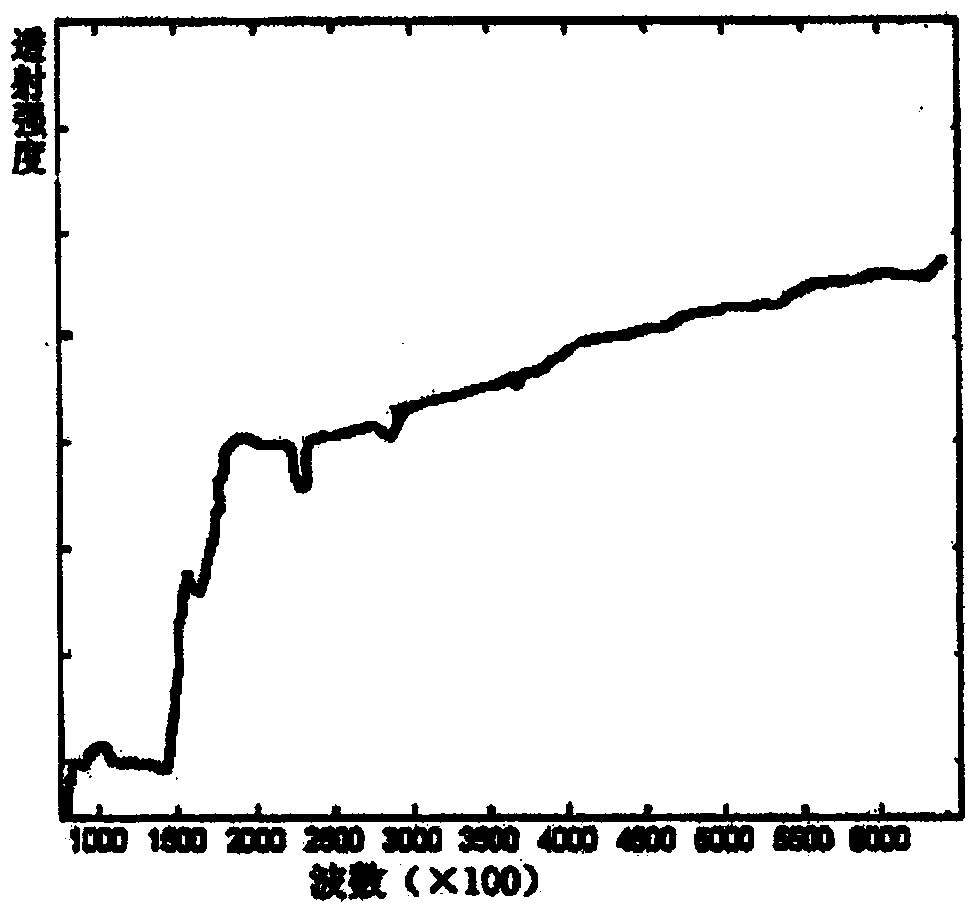

[0029] 4. Depositing InSb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com