Method for preparing ethyl alcohol by adopting carrier fermenting technique

A technology, ethanol technology, is applied in the field of ethanol preparation by carrier fermentation technology, which can solve the problems of no recovery of fermented strains, inability to perform high-density fermentation, and no immobilization of strains, so as to avoid substrate inhibition and reduce immobilization. Cost, effect of preventing sugar accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for producing ethanol through synchronous saccharification and fermentation of mycelium as carrier and fermentation strain:

[0034] 1. Inoculate Saccharomyces cerevisiae strains into a 250ml Erlenmeyer flask containing 100ml of seed medium according to the inoculum amount of 5%, culture it in a shaker at 30°C and 100r / min for 30 hours, and centrifuge the fermentation broth at 5000r / min for 5min. Yeast cells were collected; the seed medium was yeast extract 10 g / L, peptone 20 g / L, glucose 20 g / L, and natural pH.

[0035] 2. Make Aspergillus niger into a spore suspension with sterile water, inoculate it into a 250ml Erlenmeyer flask containing 100ml of enzyme-producing medium according to the inoculum amount of 4%, and cultivate it in a shaker at 30°C and 40r / min for 18h, and the spores OD of the expanded culture of the suspension 600 The value is 0.4. Wherein, the formula of enzyme-producing medium is Jerusalem artichoke powder 25g / L, (NH 4 ) 2 SO 4 5g / L,...

Embodiment 2

[0040] Ethanol was prepared by the following method:

[0041] 1. Inoculate the Saccharomyces cerevisiae strain into a 250ml Erlenmeyer flask containing 100ml seed medium according to the inoculum amount of 8%, culture it in a shaker at 30°C and 100r / min for 30 hours, and centrifuge the fermentation broth at 5000r / min for 5min. Yeast cells were collected; the seed medium was yeast extract 10 g / L, peptone 20 g / L, glucose 20 g / L, and natural pH.

[0042] 2. Make Aspergillus niger into a spore suspension with sterile water, inoculate it into a 250ml Erlenmeyer flask containing 100ml of enzyme-producing medium according to the inoculation amount of 2%, and cultivate it in a shaker at 30°C and 40r / min for 18h, and the spores OD of the expanded culture of the suspension 600 The value is 0.5. Wherein, the formula of enzyme-producing medium is Jerusalem artichoke powder 25g / L, (NH 4 ) 2 SO 4 5g / L, peptone 10g / L, KH 2 PO 4 6 g / L, NaCl 5 g / L, MgSO 4 ·7H 2 O 0.5g / L, FeSO 4 ·7H...

Embodiment 3

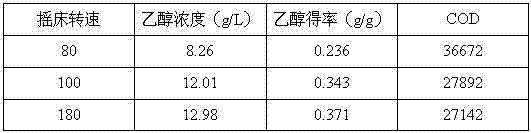

[0047] Study on the influence of the formation of mixed mycelium balls on the fermentation effect under different rotational speed conditions

[0048] Ethanol is prepared by fermentation according to the method of Example 1, the difference is: in step 3, when Aspergillus niger and Saccharomyces cerevisiae are mixed cultured, the shaker speed is mixed according to 80r / min, 100r / min, 180r / min, and the final obtained ethanol The performance parameters are as follows.

[0049]

[0050] Through the comparison of Example 1 and the above data, it can be seen that the rotating speed of the shaking table has a great influence on the formation of mixed mycelium balls, the yield of ethanol, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com