Polyurethane polymer capable of rapidly decomposing, preparation method and applications thereof

A polyurethane polymer, rapid degradation technology, applied in the field of polyurethane polymer and its preparation, can solve the problems of high cost, secondary pollution, secondary pollution cost, etc., achieve good degradation performance, solve pollution problems, good mechanical properties and The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

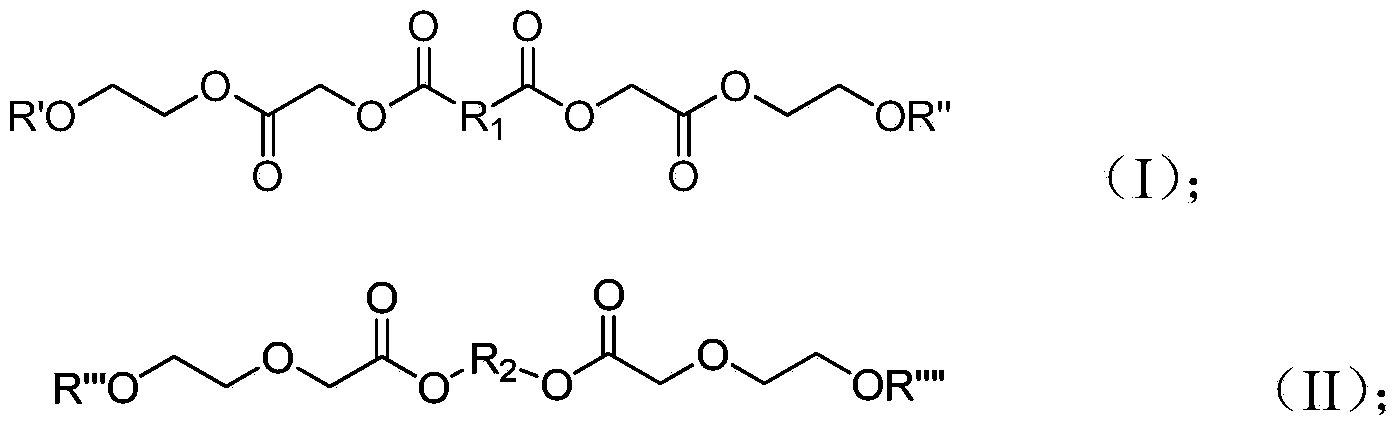

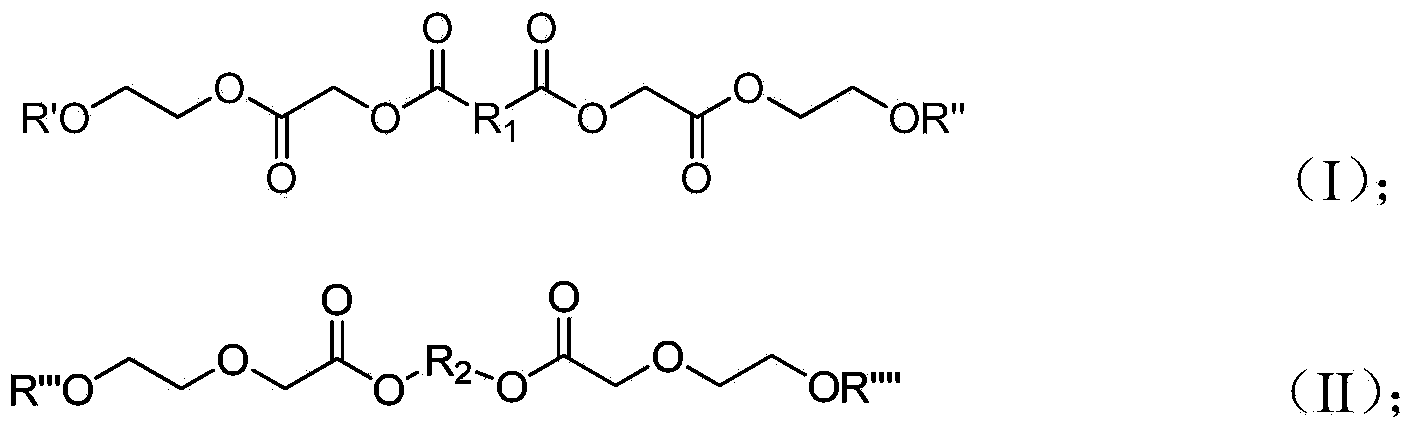

Method used

Image

Examples

Embodiment 1

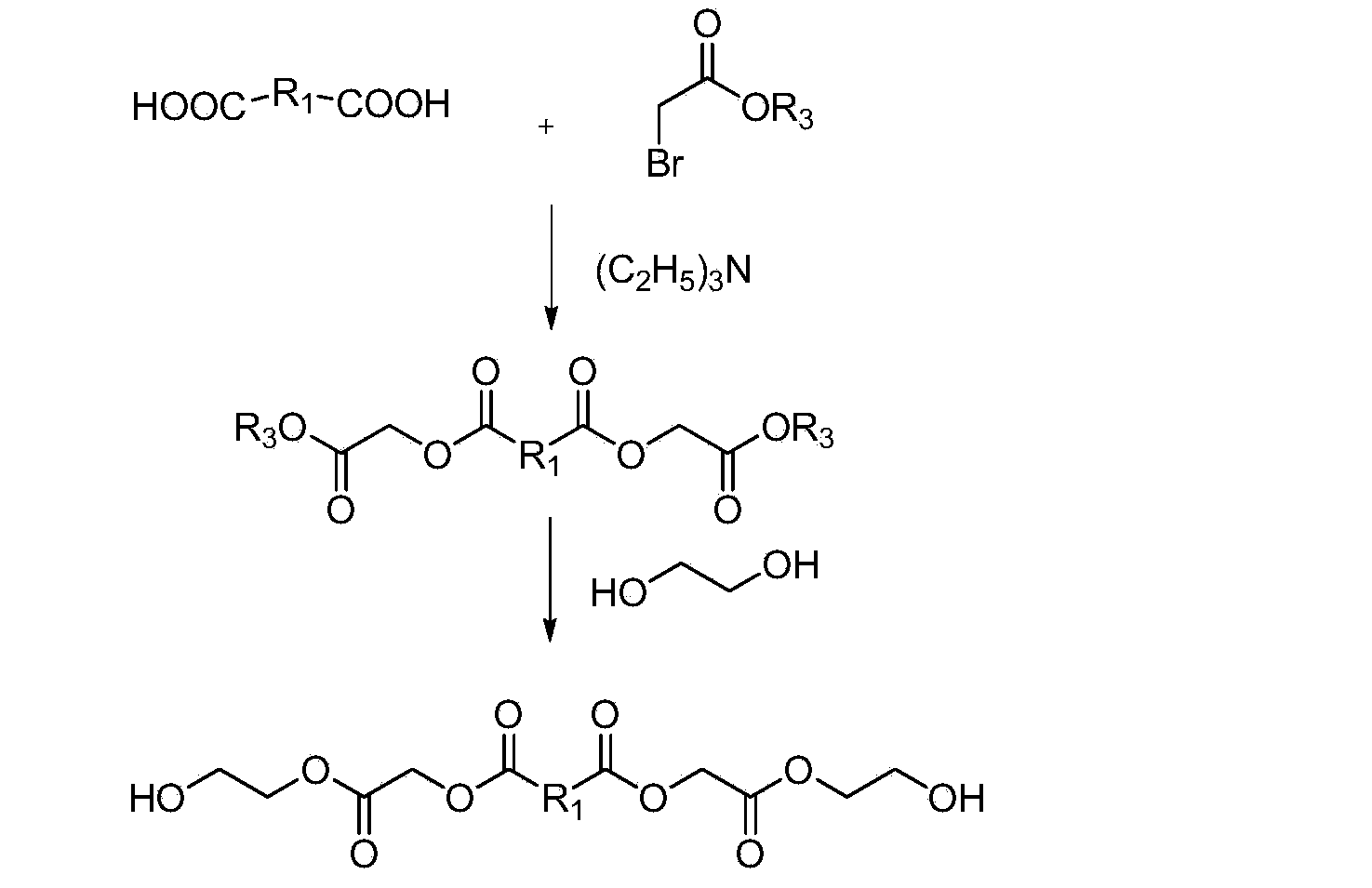

[0043] Put 11.8g (0.1mol) of succinic acid and 5.3g (0.05mol) of sodium carbonate into 100ml of acetonitrile solution; add 36.7g (0.24mol) of methyl bromoacetate to the system; after the addition, react at 30°C for 2h, remove Solvent, filter, dry the filter residue, wash with water to remove the salt on the surface, and obtain it.

[0044] Add 6.55 g (0.025 mol) of the compound obtained above to 6.2 g (0.1 mol) ethylene glycol solution, add 0.02 g ethylene glycol antimony to the above solution, protect the mixture with nitrogen, and raise the temperature to 80° C. for 6 hours. Finally, the excess ethylene glycol was removed by vacuuming with an oil pump, and the measured hydroxyl value index was 174.1, and the degraded polyol DR-1 was obtained. The structural formula of DR-1 is:

[0045]

Embodiment 2

[0047] Dissolve 21.44g (0.21mol) of p-dioxanone in 100ml of acetonitrile solution, add 6.2g (0.10mol) of ethylene glycol to the solution, add 0.064g of zinc lactate, stir at room temperature for 30min, heat up to 60°C for 24h , and then remove the solvent and excess p-dioxanone in a vacuum at 3 mmHg, and the measured hydroxyl value index is 210.7, and the degraded segment DR-2 can be obtained. The structural formula of DR-2 is:

[0048]

Embodiment 3

[0050]Dissolve 21.44g (0.21) p-dioxanone in 100ml of acetonitrile solution, add 10.4g (0.1mol) of neopentyl glycol to the solution, add 0.055g of zinc lactate, stir at room temperature for 30min, heat up to 60°C for 24h , and then remove the solvent and excess dioxanone under vacuum at 3 mmHg, and the measured hydroxyl value index is 182.0, and DR-3 can be obtained. The structural formula of DR-3 is:

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com