Refractive index of 1.67 blue light level protective resin lens and preparation method thereof

A resin lens, refractive index technology, applied in the field of optical lenses, can solve the problems of aggravating chromatic aberration and visual blur, increasing the distance of light chromatic aberration, strengthening the blood supply to the eyes, etc., to achieve excellent adhesion, reduce tingling and soreness, The effect of preventing cataract and macular degeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

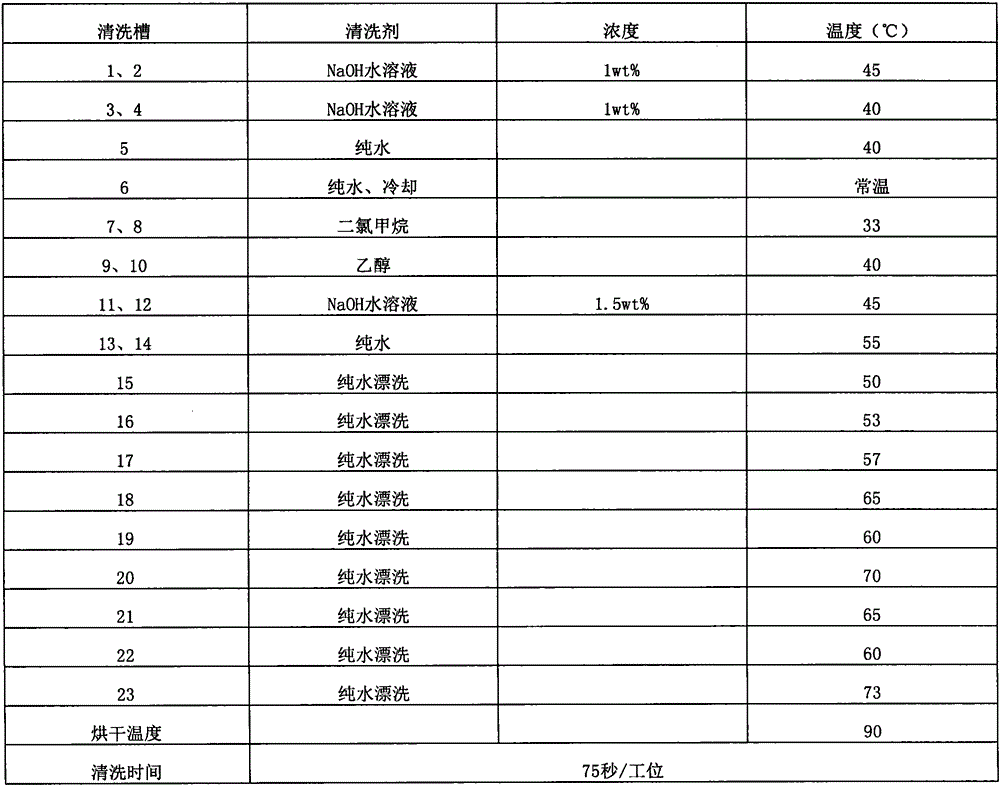

[0025] The blue-light grade protective resin lens described in the present embodiment, its resin substrate is made of 560 parts by weight of p-xylene diisocyanate MR-7A, 440 parts by weight of 2,3-bis((2-mercaptoethyl)sulfanyl)-1 - propanethiol MR-7B, 0.4 parts by weight dimethyl tin dilauryl mercaptide, 3 parts by weight UV-366, 5 parts by weight UV-329 and 2 parts by weight triphenyl phosphite; its preparation The process includes batching, filling, primary curing, substrate treatment, secondary curing and substrate cleaning:

[0026] 1. Ingredients

[0027] 1.1 Weighing of raw materials: p-xylene diisocyanate MR-7A: 560 parts by weight, 2,3-bis((2-mercaptoethyl)thio)-1-propanethiol MR-7B: 440 parts by weight, dimethyl Base tin dilauryl mercaptide: 0.4 parts by weight, UV-329: 5 parts by weight, UV-366: 3 parts by weight, triphenyl phosphite: 2 parts by weight;

[0028] 1.2 Mixing and stirring: add the above-mentioned accurately weighed various raw materials into the stirr...

Embodiment 2

[0059] The blue-light grade protective resin lens described in this embodiment, its resin substrate is made of p-xylene diisocyanate MR-7A-560 parts by weight, 2,3-bis((2-mercaptoethyl)sulfanyl)-1-propane Mercaptan MR-7B: 440 parts by weight, dimethyl tin dilauryl mercaptide: 0.4 parts by weight, 3 parts by weight dihydroxyethylglycine, 22 parts by weight diethylene glycol diacrylate, UV-329: 5 Parts by weight, UV-366: 3 parts by weight, triphenyl phosphite: 2 parts by weight; its preparation process includes steps such as batching, filling, primary curing, substrate treatment, secondary curing and substrate cleaning:

[0060] 1. Ingredients

[0061] 1.1 Weighing of raw materials: p-xylene diisocyanate MR-7A: 560 parts by weight, 2,3-bis((2-mercaptoethyl)thio)-1-propanethiol MR-7B: 440 parts by weight, dimethyl Base tin dilauryl mercaptide: 0.4 parts by weight, dihydroxyethylglycine: 3 parts by weight, diethylene glycol diacrylate: 22 parts by weight, UV-329: 5 parts by weigh...

Embodiment 3

[0093]Compared with Example 1, the difference is only in the third SiO 2 A waterproof film layer is deposited on the film layer, and the water vapor transmission rate is lower than 3×10 under the conditions of 25°C and 90% R.H. -4 gm -3 the day -1 ; wherein the waterproof film layer is prepared by PECVD method, wherein the deposition temperature is 100 ~ 120 ° C, with 0.50Wcm -2 The power is applied to the plasma, the working pressure is 200-250Pa, the flow rate of silane is 100sccm, the flow rate of methane is 20sccm, the flow rate of ammonia is 300sccm, the flow rate of nitrogen is 2000sccm, the flow rate of hydrogen is 5000sccm, and the thickness of the waterproof film layer is 1.5~3.5μm. The waterproof film layer has extremely excellent waterproof performance, which can ensure that the resin lens of the present invention maintains a blue light filtering rate of 45-50% within 3-5 years.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com