Catalyst for synthesizing methyl formate by virtue of gas-phase methanol carbonylation as well as preparation method and application of catalyst

A gas-phase methanol, methyl formate technology, applied in the direction of carbon monoxide or formate reaction preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the difficult separation of catalyst and product, practical Difficulty in operation, inability to produce normally, etc., to achieve the effect of low impurity content, high selectivity and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

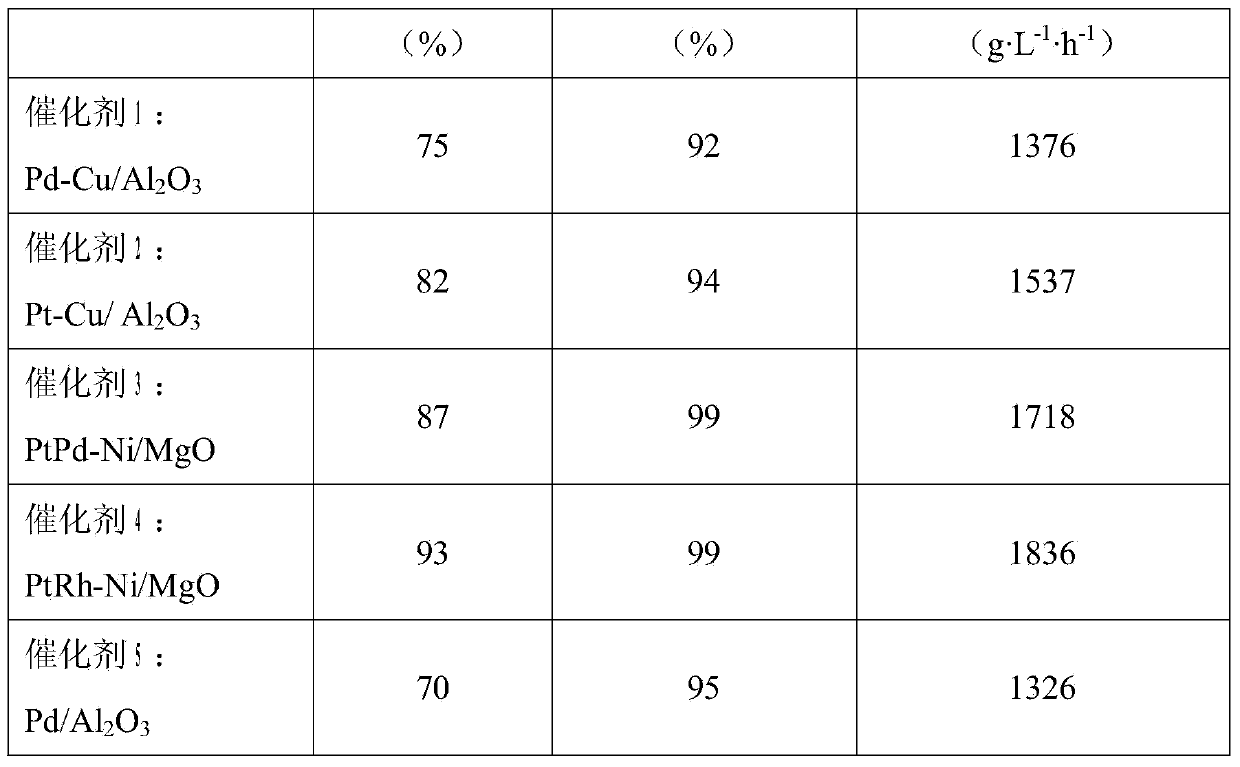

Embodiment 1

[0030] Weigh 1g of alumina and impregnate it into 15mL of 50mmol / L CuCl 2 2H 2 O ethanol solution, let it stand for 18 hours, dry at 100°C for 15 hours, roast at 400°C for 5 hours, then re-immerse in 1.25mL of 37.6mmol / L potassium chloropalladate aqueous solution, then add 4mL of water, stir for 3 hours, Ultrasonic dispersion for 3 hours, drying at 120°C for 15 hours, roasting at 400°C for 5 hours, adding 0.1g ascorbic acid, 0.2g citric acid, 0.5g polyvinylpyrrolidone, reducing at 90°C for 1 hour, and drying at 60°C for 15 hours in a vacuum. Pd-Cu / Al in the Gas-Phase Methanol Carbonylation to Methyl Formate 2 o 3 Catalyst 1.

Embodiment 2

[0032] Weigh 1g of alumina and impregnate it into 15mL of 50mmol / L CuCl 2 2H 2 O ethanol solution, let it stand for 18 hours, dry at 100°C for 15 hours, bake at 400°C for 5 hours, then re-immerse in 0.68mL of 37.6mmol / L aqueous solution of chloroplatinic acid, add 4mL of water, stir for 3 hours, and ultrasonically disperse For 3 hours, dry at 120°C for 15 hours, roast at 400°C for 5 hours, add 0.1g ascorbic acid, 0.2g citric acid, 0.5g polyvinylpyrrolidone, reduce at 90°C for 1 hour, and dry at 60°C for 15 hours in a vacuum, then it will be used in gas phase methanol Pt-Cu / Al in Carbonylation Synthesis of Methyl Formate2 o 3 Catalyst 2.

Embodiment 3

[0034] Weigh 1g of Ni(NO) of magnesia 17mL50mmol / L 3 ) 2 ·6H 2 In O ethanol solution, let stand for 18 hours, dry at 100°C for 15 hours, roast at 400°C for 5 hours, then re-impregnate into 0.63mL37.6mmol / L of potassium chloropalladate and 0.34mL37.6mmol / L of chloroplatinic acid Add 4mL of water to the aqueous solution, stir for 3 hours, ultrasonically disperse for 3 hours, dry at 120°C for 15 hours, bake at 400°C for 5 hours, add 1mL of formaldehyde, 0.24g of sodium citrate, 0.6g of polyethylene oxide-polyepoxide Propane-polyethylene oxide triblock copolymer was reduced at 100°C for 2 hours and dried at 60°C in vacuum for 15 hours to obtain PtPd-Ni / MgO catalyst 3 for the gas-phase methanol carbonylation to methyl formate reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com