Oil-resistant fluorinated silicone rubber and preparation method thereof

A fluorosilicone rubber and oil-resistant technology, which is applied in the field of oil-resistant fluorosilicone rubber and its preparation, can solve the problems of large swelling rate, increased cost, and increased dosage of vulcanizing agent, etc., to achieve improved oil resistance, improved dispersion and compatibility, The effect of excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

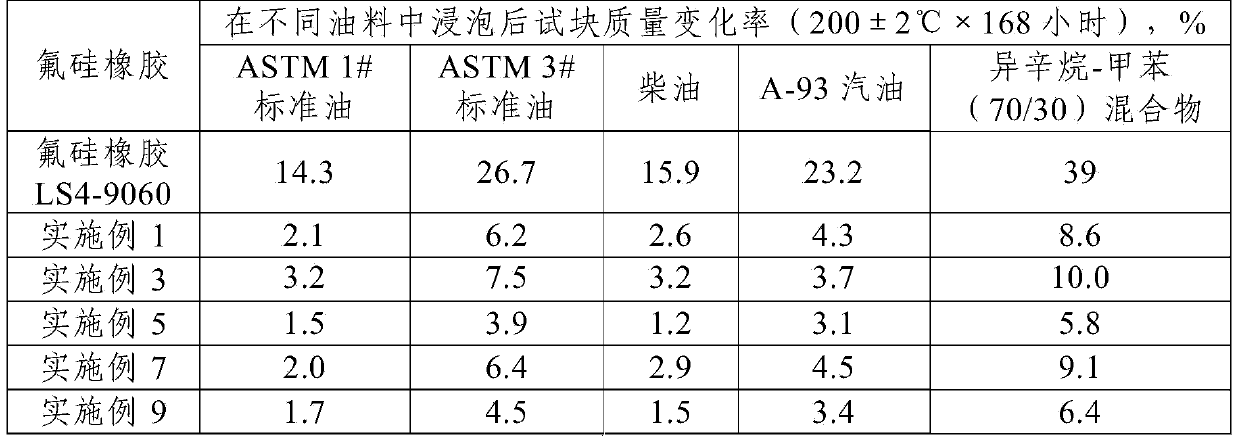

Examples

Embodiment 1

[0028] Step 1, adding alumina powder and polyethylene glycol to distilled water to make a dispersion with a mass percentage of alumina of 5%, and then mixing the n-butanol solution of coconut oleic acid with the alumina dispersion at a ratio of 1:10 After mass ratio mixing, azeotropic distillation is carried out under stirring conditions, the filter cake is washed, and then ultrasonically dispersed in absolute ethanol until the absolute alcohol is completely volatilized, then dried and ground to obtain modified alumina powder; the alumina The mass ratio of powder and Polyethylene Glycol is 100:1; In the n-butanol solution of described coconut oleic acid, the mass ratio of coconut oil and n-butanol is 1:20;

[0029] Step 2: Mix 100g of fluorosilicone rubber LS4-9060, 10g of N990 carbon black, 60g of modified alumina powder and 0.03g of stearic acid in step 1 on the open mill, and cool to At room temperature, the masterbatch was obtained; the mixing temperature was 120°C, and th...

Embodiment 2

[0032] The present embodiment is the same as Example 1, wherein the difference is that the carbon black used is spray carbon black, and the vulcanizing agent used is dicumyl peroxide, benzoyl peroxide, 2,4-dichlorobenzoyl peroxide acyl or di-tert-butyl peroxide cumene.

Embodiment 3

[0034] Step 1, adding alumina powder and polyethylene glycol into distilled water to make a dispersion with a mass percent content of alumina of 8%, and then mixing the n-butanol solution of coconut oleic acid with the alumina dispersion at a ratio of 1:10 After mass ratio mixing, azeotropic distillation is carried out under stirring conditions, the filter cake is washed, and then ultrasonically dispersed in absolute ethanol until the absolute alcohol is completely volatilized, then dried and ground to obtain modified alumina powder; the alumina The mass ratio of powder and Polyethylene Glycol is 100:1; In the n-butanol solution of described coconut oleic acid, the mass ratio of coconut oil and n-butanol is 1:20;

[0035] Step 2: Mix 100g of fluorosilicone rubber LS4-9060, 3g of sprayed carbon black, 30g of modified alumina powder and 0.01g of stearic acid in Step 1 on an open mill, and then cool down to At room temperature, the masterbatch was obtained; the mixing temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com