Corrosion-resistant and wear-resistant pipe coating and preparation method thereof

An anti-corrosion and wear-resistant, coating technology, applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of high stress concentration damage, easy surface wear, low wear resistance, etc. The effect of long service life, high adhesion, strong corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

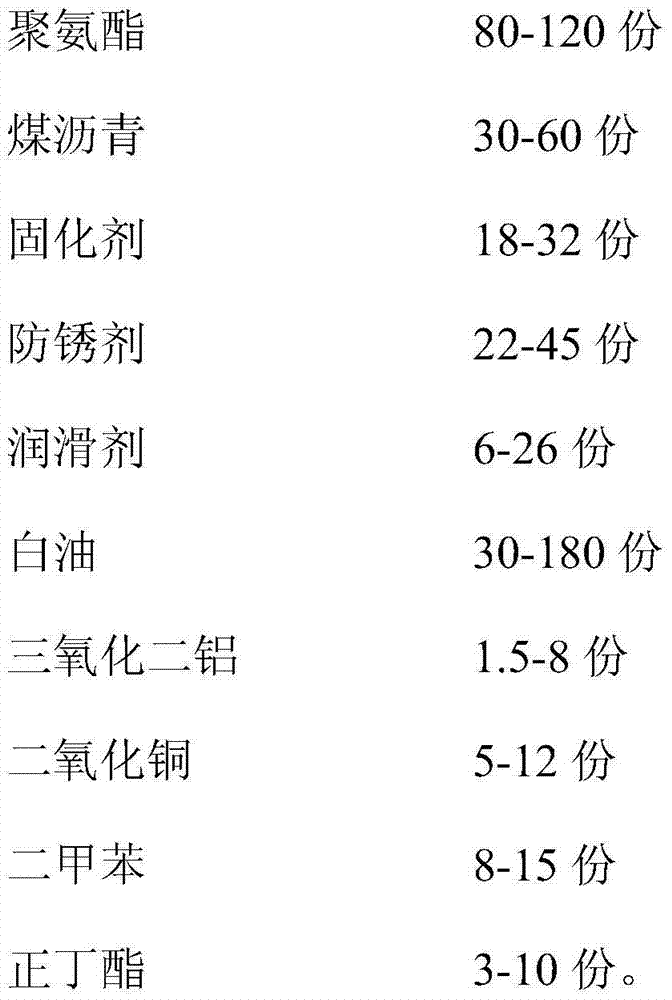

Method used

Image

Examples

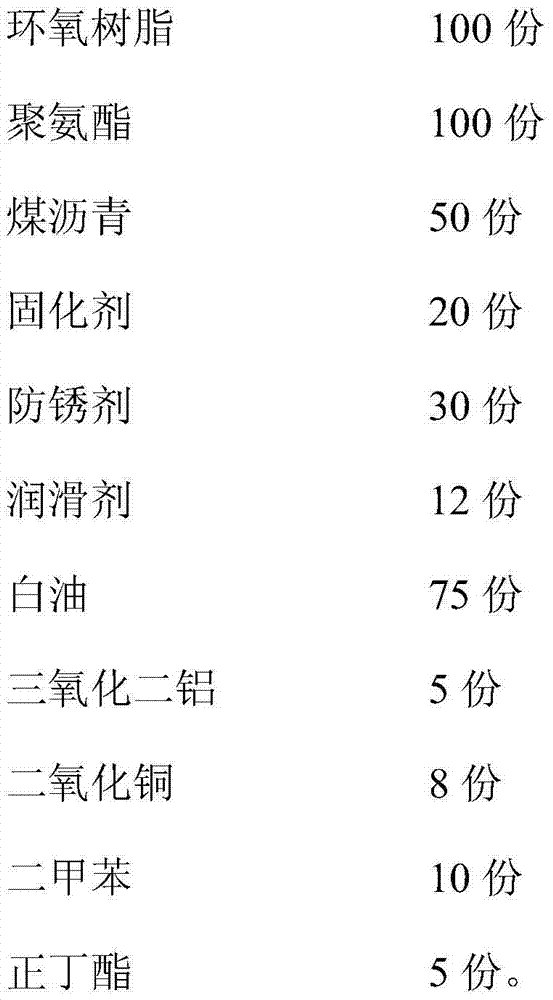

example 1

[0022] A preparation method of an anti-corrosion and wear-resistant pipe coating, the preparation method is as follows:

[0023] (1) Put 75 parts by weight of white oil and 50 parts of coal tar pitch into the cooking kettle, stir, heat to 115°C, and keep warm for 25 minutes to obtain a mixed solution;

[0024] (2) Prepare a curing agent, mix calcium carbonate, barium sulfate, and mica powder in a weight ratio of 1:1:1 to obtain a curing agent, and set aside;

[0025] (3) Prepare antirust agent, mix zinc phosphate and organic chromate in a weight ratio of 1:2 to obtain antirust agent, set aside;

[0026] (4) Prepare a lubricant, mix stearic acid, paraffin wax, and oxidized polyethylene wax in a weight ratio of 1:2:1, and prepare the lubricant for later use;

[0027] (5) Pump the mixed solution into the paint tank, add 20 parts by weight of curing agent, 30 parts of rust inhibitor, and 12 parts of lubricant in sequence, stir for 10 minutes, and then add 5 parts of dioxide Alum...

example 2

[0032] A preparation method of an anti-corrosion and wear-resistant pipe coating, the preparation method is as follows:

[0033] (1) Put 45 parts by weight of white oil and 45 parts of coal tar pitch into the cooking kettle, stir, heat to 115°C, and keep warm for 25 minutes to obtain a mixed solution;

[0034] (2) Prepare a curing agent, mix calcium carbonate, barium sulfate, and mica powder in a weight ratio of 1:1:1 to obtain a curing agent, and set aside;

[0035] (3) Prepare antirust agent, mix zinc phosphate and organic chromate in a weight ratio of 1:2 to obtain antirust agent, set aside;

[0036] (4) Prepare a lubricant, mix stearic acid, paraffin wax, and oxidized polyethylene wax in a weight ratio of 1:2:1, and prepare the lubricant for later use;

[0037] (5) Pump the mixed solution into a paint tank, add 18 parts by weight of curing agent, 25 parts of rust inhibitor, and 8 parts of lubricant in sequence, stir for 10 minutes, and then add 3 parts of dioxide Aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

| Wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com