Energy-saving waste gas treatment method and apparatus thereof

A waste gas treatment device and waste gas treatment technology are applied in the direction of ion exchange treatment devices, separation methods, chemical instruments and methods, etc., which can solve the problems of affecting the cooling water heating system, heavy pressure, cross-contamination, etc., and improve the use of equipment High efficiency, low resistance, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Target experimental exhaust gas

[0047] Treatment of waste gas from nitric acid heating process, the main pollutants are nitrogen oxides. During the experiment, three nitric acid beakers were heated at the same time, and the volatilization of nitrogen oxides was 210mg / m 3 , the discharge of the fume hood is 1700m 3 / h.

[0048] 2. Process parameters

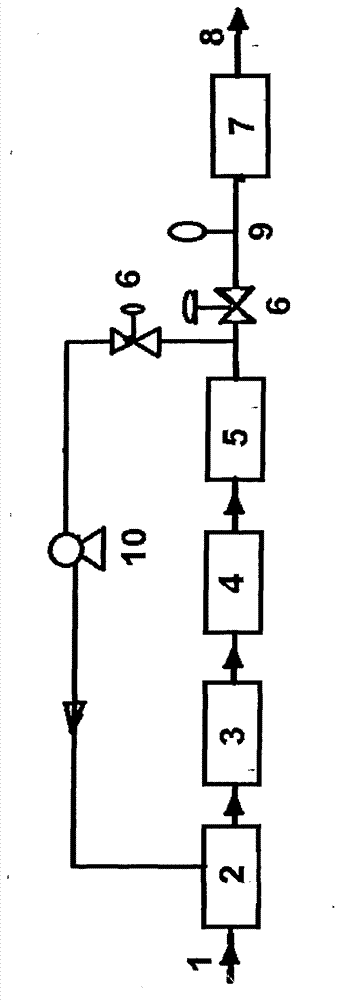

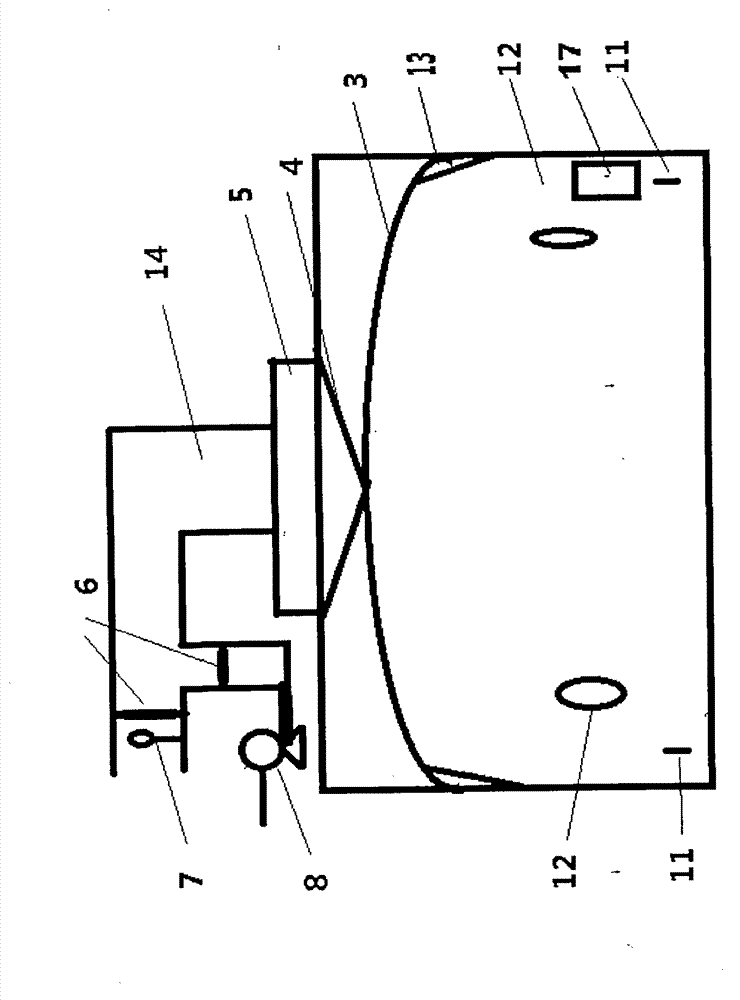

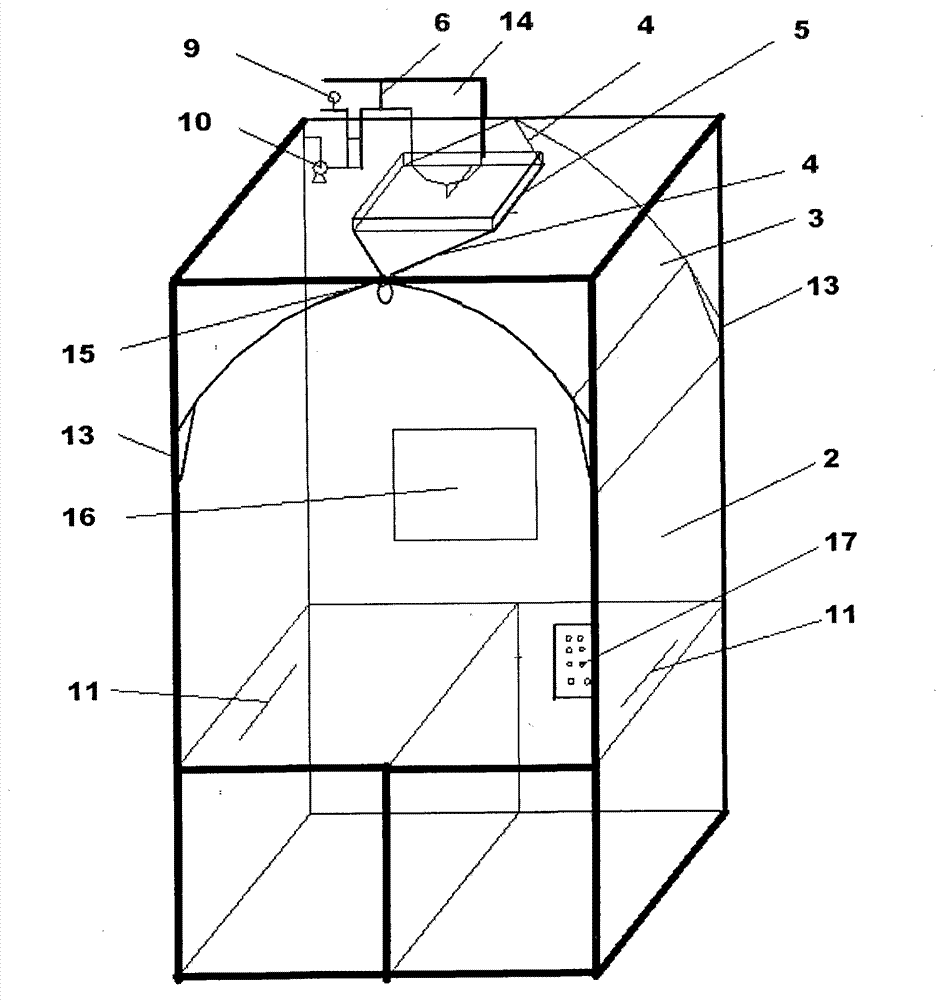

[0049] use as figure 2 and image 3 For the shown device, the specific process parameters are as follows:

[0050] (1) Ion exchange resin membrane 3: The effective filtration area is 2.25m 2 , consisting of two pieces. It is Clean-Q501 ion exchange resin membrane with a thickness of 5mm.

[0051] (2) Activated carbon fiber adsorption layer 3: effective filtration area 1.5m 2 , which is composed of four activated carbon fiber adsorption layers, which is ordinary activated carbon fiber.

[0052] (3) Nanophotocatalytic device: size: 500*300*150mm, ceramic solid-carrying material per 100*100*50mm; ultraviolet la...

Embodiment 2

[0058] 1. Target experimental exhaust gas

[0059] The formaldehyde is heated, and the three formaldehyde reactions are carried out simultaneously.

[0060] 2. Process parameters

[0061] use as figure 2 and image 3 For the shown device, the specific process parameters are as follows:

[0062] (1) Ion exchange resin membrane 3: The effective filtration area is 2.25m 2 , consisting of two pieces. It is Clean-Q501 ion exchange resin membrane with a thickness of 5mm.

[0063] (2) Activated carbon fiber adsorption layer 3: effective filtration area 1.5m 2 , which consists of four activated carbon fiber adsorption layers, which are ordinary activated carbon fibers.

[0064] (3) Nanophotocatalytic device: size: 500*300*150mm, ceramic solid-carrying material per 100*100*50mm; ultraviolet lamps, 4, 245nm; bismuth vanadate usage 10g, rhenium oxide usage 0.3g.

[0065] (4) The recycled gas ratio is 50%.

[0066] It is found through experimental testing that the treatment effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com