Preparation method of multi-component nano catalyst

A nano-catalyst, multi-component technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of reducing, difficult to guarantee nano-copper particles, and difficult to achieve Pt dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation method of copper platinum core-shell (CuPt) nano material

[0032] Under 80°C argon atmosphere with magnetic stirring, 45mg (0.172mmol) copper acetylacetonate (Cu(acac) 2 ) And 17.3mg polyvinylpyrrolidone (PVP K30 ) Dissolve in 25mL ethylene glycol (EG), keep stirring for 30 minutes until both are dissolved; quickly heat to 198°C, reflux for 3 hours, and then quickly cool to 0°C to obtain a suspension, namely ethylene glycol Dispersed Cu nanoparticles; further increase the temperature of the suspension to 80°C, and add 17.5mg platinum dichloride (PtCl) under an argon atmosphere 2 ), fully agitate to completely dissolve it, quickly raise the temperature to 130°C, keep it for 4 hours, and quickly store it in an ice bath, and finally obtain ethylene glycol-dispersed CuPt nanoparticles.

Embodiment 2

[0034] Preparation method of supported copper platinum core-shell (CuPt / CB) catalytic material

[0035] To the ethylene glycol-dispersed CuPt nanoparticles obtained in [Example 1], 50 mL of acetone was added, and after stirring for 20 minutes, centrifuged at 1000 rpm for 30 minutes to remove the supernatant. Repeat the above steps three times to obtain a precipitate, then quickly disperse the precipitate in 20 mL of ethanol under ultrasonic conditions, and add 1 g of carbon black (CB), stir to dryness, and dry overnight at 60°C to obtain 1.1 wt% Cu and CuPt / CB catalytic material with 0.9wt% Pt loading.

Embodiment 3

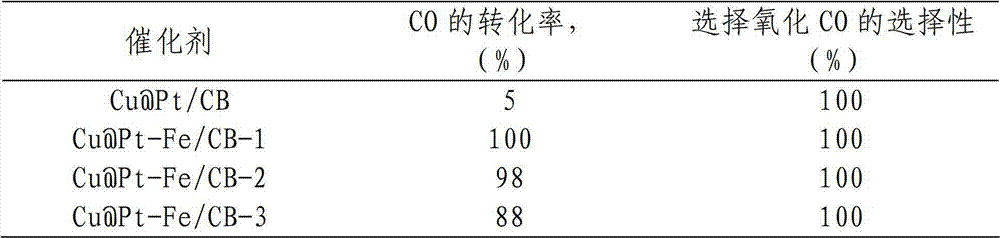

[0037] Preparation method of supported nano-copper core single-layer platinum shell stabilized nano-iron island catalytic material with different loading capacity (CuPt-Fe / CB)

[0038] (A) Take 0.2 g of the CuPt / CB catalytic material obtained in [Example 2], place it in a 100mL three-necked flask, add 20mL (0.05M) hydrochloric acid and 10mL (3mM) ferric nitrate solution, and stir vigorously for 30 minutes. Blow hydrogen under the liquid surface (maintain the hydrogen pressure at 1.2 bar), and maintain the hydrogen atmosphere for 1.5 hours. Then take it out, filter, rinse with 1L deionized water, and dry overnight at 60°C to obtain a CuPt-Fe / CB-1 catalytic material with a loading amount of 0.1wt% Fe, 1.1wt% Cu and 0.9wt% Pt. Calculated as a benchmark.

[0039] (B) Take 0.2 g of the CuPt / CB catalytic material obtained in [Example 2], place it in a 100mL three-necked flask, add 20mL (0.05M) hydrochloric acid and 10mL (17mM) ferric nitrate solution, and stir vigorously for 30 minutes....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com