Nano-silver/poly(2-acrylamido-2-methylpropanesulfonic acid) doped polyaniline binary composite material and preparation method thereof

A technology based on acrylamide and methyl propane sulfonic acid, which is applied in the direction of silver compounds, silver compounds, chemical instruments and methods, etc., can solve the problems of poor dispersion of nano-silver, limited application, easy agglomeration, etc., and achieve low cost, Good application prospect, not easy to reunite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

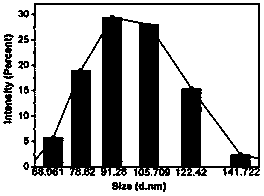

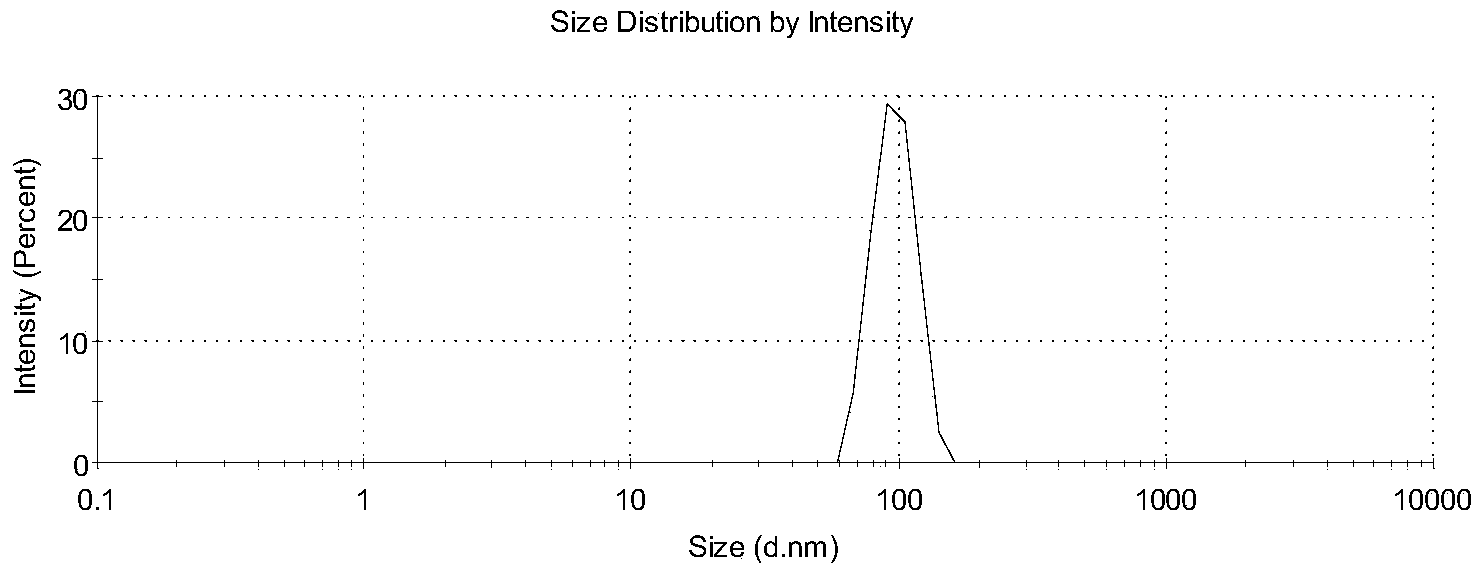

[0029] Take 5.0g of PAAMPS and add it to 95.0g of distilled water to configure a PAAMPS emulsion with a mass fraction of 5%. Dissolve 0.44g of sodium hypophosphite in 10mL of distilled water and add it to 100mL of a 5% PAAMPS emulsion with a mass fraction of 5%, followed by electric stirring for 15 Minutes later, the temperature of the reaction system was raised to 40°C, and 10 mL of silver nitrate solution containing 1.42 g was added dropwise at a rate of 15-20 drops / min, and the reaction time was 70 minutes; the nano-silver emulsion was obtained; , washed, dried, and the obtained nano-silver is detected, and the particle size distribution of nano-silver particles is as follows: figure 2 with image 3 The scanning electron microscope image is shown in Figure 4 shown.

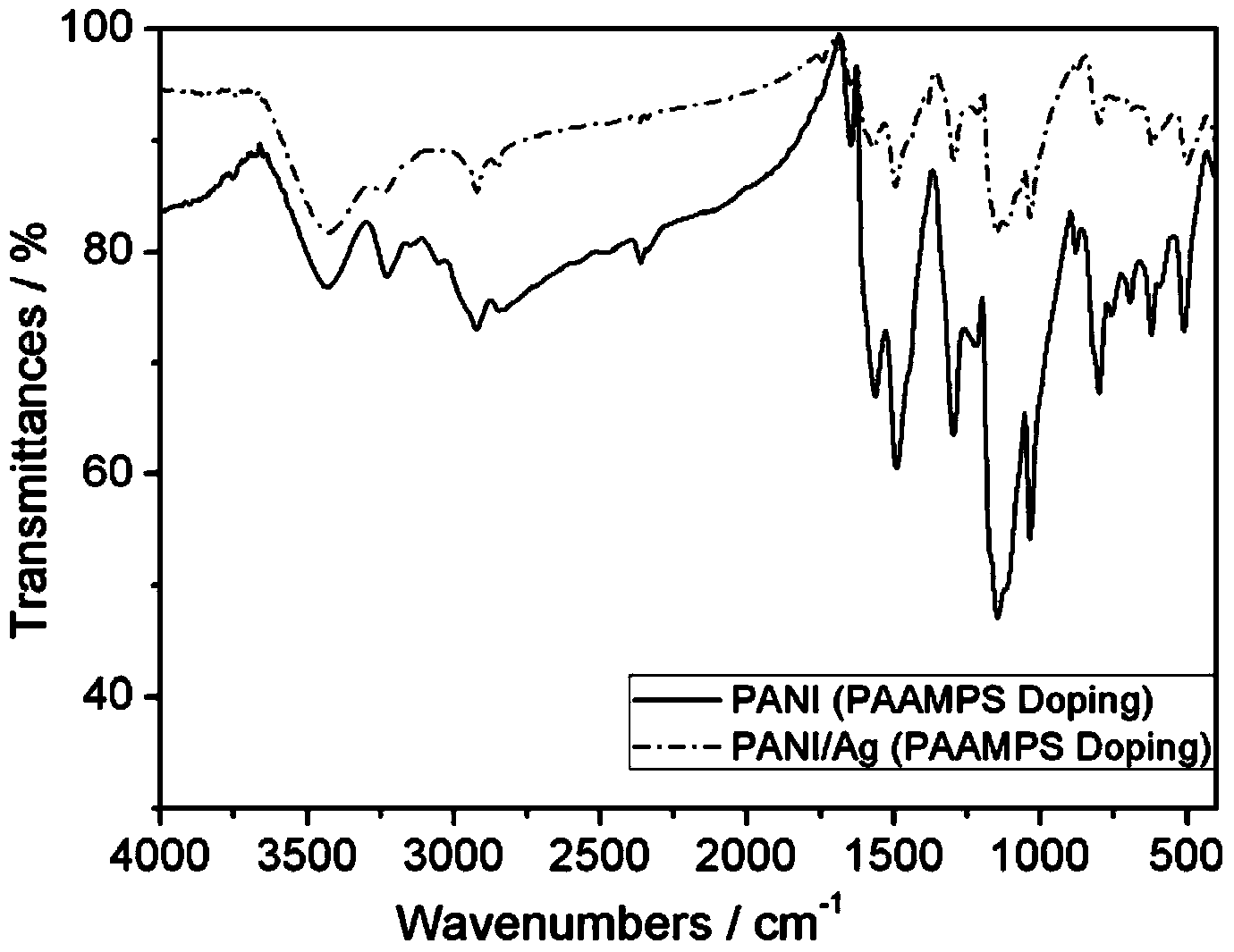

[0030] Add 2.50g of aniline to the prepared nano-silver emulsion, and after ultrasonic dispersion for 10 minutes, add 30mL of an aqueous solution containing 5.71g of ammonium persulfate dropwise to the reac...

Embodiment 2

[0033] Take 15.0g of PAAMPS and add it into 85.0g of distilled water to configure a PAAMPS emulsion with a mass fraction of 15%. Dissolve 0.88g of sodium hypophosphite in 10mL of distilled water and add it to 100mL of a mass fraction of 15% PAAMPS emulsion, followed by electric stirring for 15 Minutes later, the temperature of the reaction system was raised to 40°C, and 10 mL of silver nitrate solution containing 2.84 g was added dropwise, the dropping rate was controlled at 15-20 drops / min, and the reaction time was 70 minutes; the silver nano-emulsion was obtained;

[0034] Add 2.50 g of aniline to the prepared nano-silver microemulsion, and ultrasonically disperse it for 10 minutes. Then, under electric stirring, add 30 mL of an aqueous solution containing 5.71 g of ammonium persulfate dropwise to the reaction system to initiate the polymerization of aniline at a rate of 15 to 20 drop / min, the reaction temperature is controlled at 0-5°C, and the reaction time is 12 hours; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com