Electrochemical luminescence sensor for detecting pesticide carbaryl and preparation method thereof

A carbaryl and sensor technology, applied in the field of electrochemiluminescence sensing, can solve the problems of poor water solubility and poor water solubility of graphene, and achieve the effects of low detection limit, high sensitivity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of graphene oxide-phthalocyanine composites:

[0028] GO-CoPc composites were prepared by adding 100 mg CoPc and 10 mg GO to 30 mL ionic liquid ([BMIM]PF 6 ), sonicated for 10 h, centrifuged, and washed with water in a semi-permeable membrane until the solvent [BMIM]PF 6 completely removed, then 60 o C Vacuum drying prepared GO-CoPc nanocomposites, set aside.

[0029] (2) Glassy carbon electrode (GCE) surface pretreatment:

[0030] The GCE electrode was polished with alumina powder with a particle size of 1 μm and 0.05 μm in turn, and the electrode was placed in a 5 mmol / L potassium ferricyanide solution by cyclic voltammetry, and scanned at -0.2 to 0.6 V. The peak potential difference Below 110 mV indicates that the electrode pretreatment is completed, and then ultrasonically cleaned in ethanol and double distilled water in turn, and dried with nitrogen for later use.

[0031] (3) Modification process of the ECL sensor interface:

[0032]Disperse 2...

Embodiment 2

[0034] (1) Preparation of graphene oxide-phthalocyanine composites:

[0035] GO-CoPc composites were prepared by adding 100 mg CoPc and 16 mg GO to 30 mL ionic liquid ([BMIM]PF 6 ), sonicated for 10 h, centrifuged, and washed with water in a semi-permeable membrane until the solvent [BMIM]PF 6 completely removed, then 60 o C Vacuum drying prepared GO-CoPc nanocomposites, set aside.

[0036] (2) Glassy carbon electrode (GCE) surface pretreatment:

[0037] The GCE electrode was polished with alumina powder with a particle size of 1 μm and 0.05 μm in turn, and the electrode was placed in a 5 mmol / L potassium ferricyanide solution by cyclic voltammetry, and scanned at -0.2 to 0.6 V. The peak potential difference Below 110 mV indicates that the electrode pretreatment is completed, and then ultrasonically cleaned in ethanol and double distilled water in turn, and dried with nitrogen for later use.

[0038] (3) Modification process of the ECL sensor interface:

[0039] Disperse ...

Embodiment 3

[0041] (1) Preparation of graphene oxide-phthalocyanine composites:

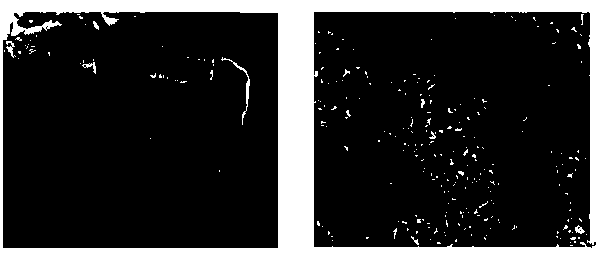

[0042] GO-CoPc composites were prepared by adding 100 mg CoPc and 25 mg GO to 30 mL ionic liquid ([BMIM]PF 6 ), sonicated for 10 h, centrifuged, and washed with water in a semi-permeable membrane until the solvent [BMIM]PF 6 completely removed, then 60 o C Vacuum drying prepared GO-CoPc nanocomposites, set aside. figure 1 (A) is GO, (B) is the transmission electron microscope image of GO-CoPc. It can be seen from the figure that CoPc is adsorbed on the surface of GO, indicating that the composite material was successfully prepared.

[0043] (2) Glassy carbon electrode (GCE) surface pretreatment:

[0044] The GCE electrode was polished with alumina powder with a particle size of 1 μm and 0.05 μm in turn, and the electrode was placed in a 5 mmol / L potassium ferricyanide solution by cyclic voltammetry, and scanned at -0.2 to 0.6 V. The peak potential difference Below 110 mV indicates that the electrode pret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com