Method for determining content of gamma-aminobutyric acid in red yeast through high-efficient liquid chromatography

A high-performance liquid chromatography, aminobutyric acid technology, applied in the field of determination of red yeast yeast components, can solve the problems of low accuracy of detection results, unstable and reliable, interference detection effect, etc., to improve detection accuracy, reduce interference, Less interference from impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

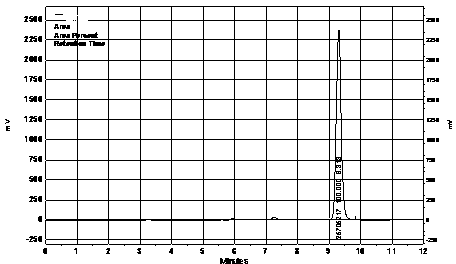

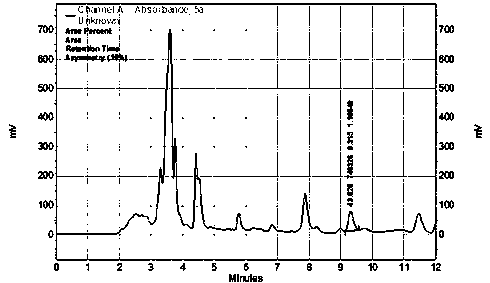

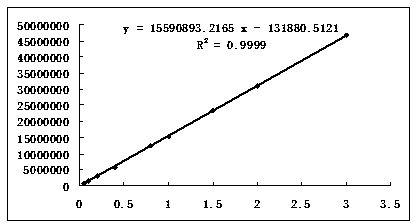

[0025] Embodiment 1: The method for measuring the content of gamma-aminobutyric acid in red yeast rice by this high-performance liquid chromatography adopts the following raw materials, instruments and process steps.

[0026] 1. The experimental equipment and reagents are as follows

[0027] 1) Instrument: Agilent 1260 high performance liquid chromatography (Agilent, USA); chromatographic column is Diamonsil C18 250 x 4.6 mm, 5 μm (Dima Technology); syringe microporous membrane; 0.22 μm organic filter membrane; spin Evaporator (Shanghai Shenke); electronic balance (Mettler-Toledo Instrument Co., Ltd.); high-speed centrifuge (Xiangyi Group); ultrasonic instrument.

[0028] 2) Experimental reagents: γ-aminobutyric acid standard, methanol, acetonitrile, formic acid, tetrahydrofuran, ultrapure water.

[0029] Second, the experiment is as follows:

[0030] 1) Experiment with γ-amino acid standard and determine the best chromatographic conditions.

[0031] 2) Use the established ...

Embodiment 2

[0066] Embodiment 2: The method for the determination of gamma-aminobutyric acid content in red yeast rice by this high performance liquid chromatography except the following difference, other is the same as embodiment 1.

[0067] (1) Sample handling:

[0068] (1) Extraction of γ-aminobutyric acid from red yeast rice samples: Accurately weigh 2.0g of red yeast rice samples and put them in a 100mL centrifuge tube; add 60ml of ultrapure water according to the mass-volume ratio of 1:30, and ultrasonically extract for 2.5 hours. Centrifuge at 5000rmp for 8 minutes to collect the supernatant; repeat the above steps 5 times, and combine the supernatants; add 1 times the volume of absolute ethanol and 1 / 10 volume of 7wt% ammonium sulfate solution, and precipitate at 0°C for 10 minutes;

[0069] (2) Centrifuge at 5000rmp for 8 minutes, discard the precipitate, concentrate under reduced pressure at room temperature to remove the solvent, then add the compound enzyme preparation, adjust...

Embodiment 3

[0074] Embodiment 3: The method for the determination of gamma-aminobutyric acid content in red yeast rice by this high performance liquid chromatography except the following difference, other is the same as embodiment 1.

[0075] (1) Sample handling:

[0076] (1) Extraction of γ-aminobutyric acid from red yeast rice samples: Accurately weigh 2.0g of red yeast rice samples and put them in a 50mL centrifuge tube; add 20ml of ultrapure water according to the mass-volume ratio of 1:10, and ultrasonically extract for 4 hours. Centrifuge at 7000rmp for 5min, collect the supernatant; repeat the above steps 4 times, combine the supernatant; add 1.5 times the volume of absolute ethanol and 1 / 5 volume of 5wt% potassium acetate solution, and precipitate at 4°C for 20min;

[0077] (2) Centrifuge at 7000rmp for 5min, discard the precipitate, concentrate under reduced pressure at room temperature to remove the solvent, then add the compound enzyme preparation, adjust the pH=3.5, and treat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com