Catalytic carbon fibers and preparation method

A technology of carbon fiber and catalytic carbon, which is applied in the fields of materials, chemistry and chemical industry, can solve problems such as complex preparation routes, achieve good chemical stability, simple equipment, and prevent aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

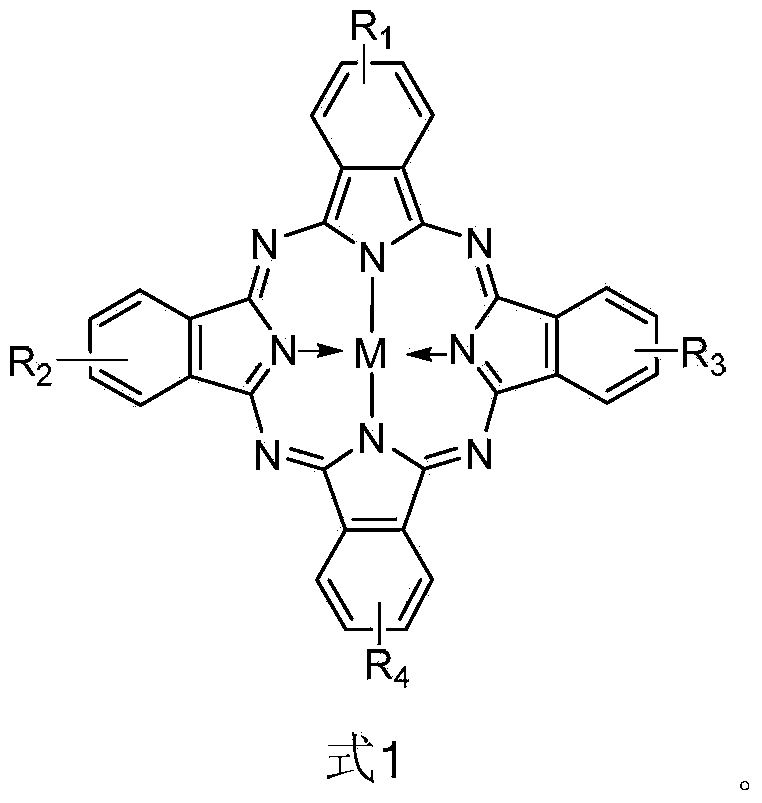

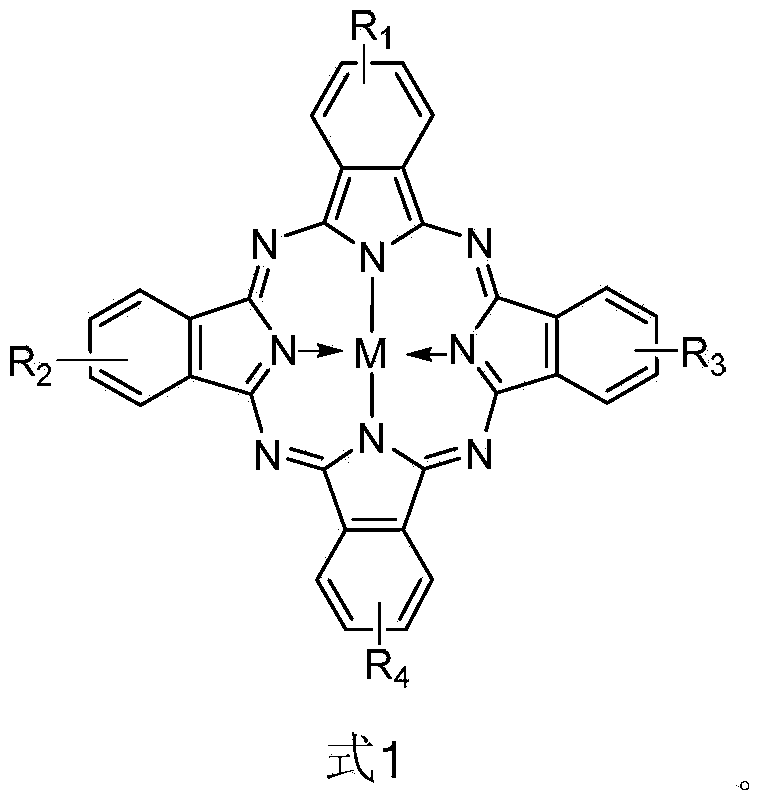

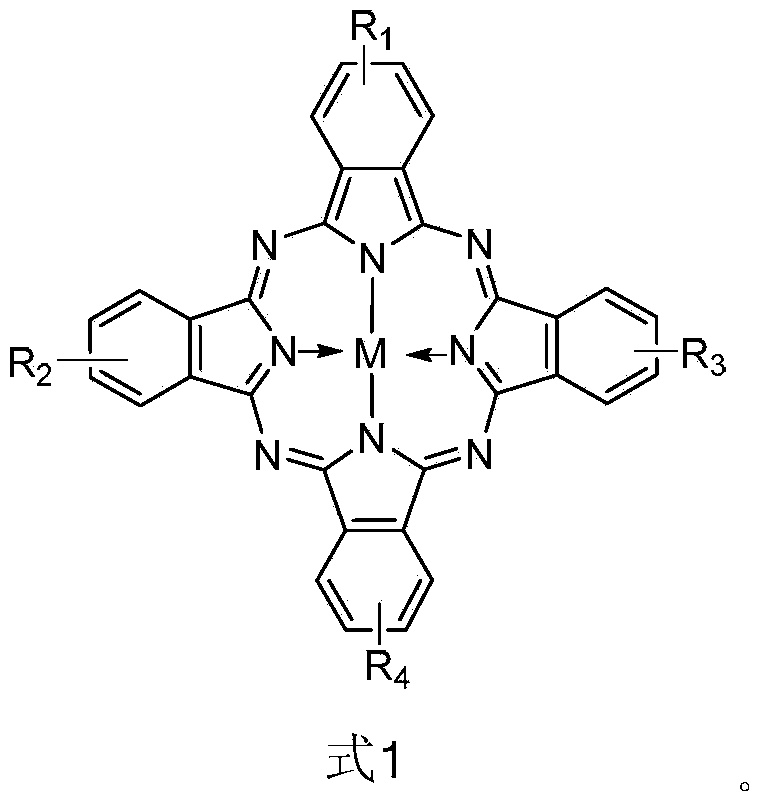

[0018] A kind of preparation method of catalytic carbon fiber as above, this preparation method selects for use containing-NH 2 The metal phthalocyanine and p-aminobenzenesulfonic acid are used as raw materials, and the carbon fiber is dispersed in the solvent at a reaction temperature of 60-90 ° C, and the -NH 2 The metal phthalocyanine, p-aminobenzenesulfonic acid and condensing agent were added therein, stirred and reacted for 2-48 hours, after the reaction was completed, the carbon fiber loaded with metal phthalocyanine was taken out, and the reaction solvent, N,N-dimethylformamide, Wash with water and ethanol, and dry at 80-100°C to obtain catalytic carbon fiber.

[0019] A method for preparing catalytic carbon fibers as described above, the preparation method is to disperse carbon fibers in a solvent under the condition that the reaction temperature is 60-90 ° C, and fully dissolve in the solvent containing -NH 2 The metal phthalocyanine and the condensing agent are add...

Embodiment 1

[0022] Weigh 0.05g of tetraaminocobalt phthalocyanine and 0.25g of p-aminobenzenesulfonic acid and dissolve them fully in 40mL and 60mL of dimethyl sulfoxide, respectively, and add dropwise to 200mL of dimethyl sulfoxide solution containing 2g of carbon fiber, at 85 Stir vigorously in an oil bath at ℃, react for 30 minutes, then add 1mL isoamyl nitrite (97%), react at 85℃ for 12 hours, finally remove the reaction solution, take out the carbon fiber loaded with cobalt phthalocyanine, and use N, N - Repeated washing with dimethylformamide, water and ethanol, and drying at 80°C to obtain 2.16g of catalytic carbon fibers.

Embodiment 2

[0024] Weigh 0.3g of tetraaminocobalt phthalocyanine and fully dissolve it in 100mL of dimethyl sulfoxide, add it dropwise to a solution of dimethyl sulfoxide (300mL) containing 6g of carbon fiber that is vigorously stirred in an oil bath at 85°C and continue stirring for 30 Minutes later, add 4 mL of isoamyl nitrite (97%), react at 85°C for 12 hours, remove the reaction solution, take out the carbon fiber loaded with cobalt phthalocyanine, and wash with N,N-dimethylformamide, water, ethanol Repeated washing and drying at 90°C yielded 6.13g of cobalt phthalocyanine-loaded carbon fibers; weighed 0.65g of p-aminobenzenesulfonic acid and fully dissolved it in 100mL of dimethyl sulfoxide, and added it dropwise to the The dimethyl sulfoxide (300 mL) solution containing 6.13 g of cobalt phthalocyanine-supported carbon fibers was stirred for 30 minutes, then 4 mL of isoamyl nitrite (97%) was added, and reacted at 85 ° C for 12 hours, and finally the reaction solution was removed. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com