A wooden door manufacturing process

A manufacturing process, wooden door technology, applied in the field of wooden door forming processing and surface finishing processing system technology, can solve the problems of lack of synchronization ability, artificial edge scraping, endangering human health, etc., to prolong the natural leveling time, improve the "mirror" level, The effect of improving the environmental protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

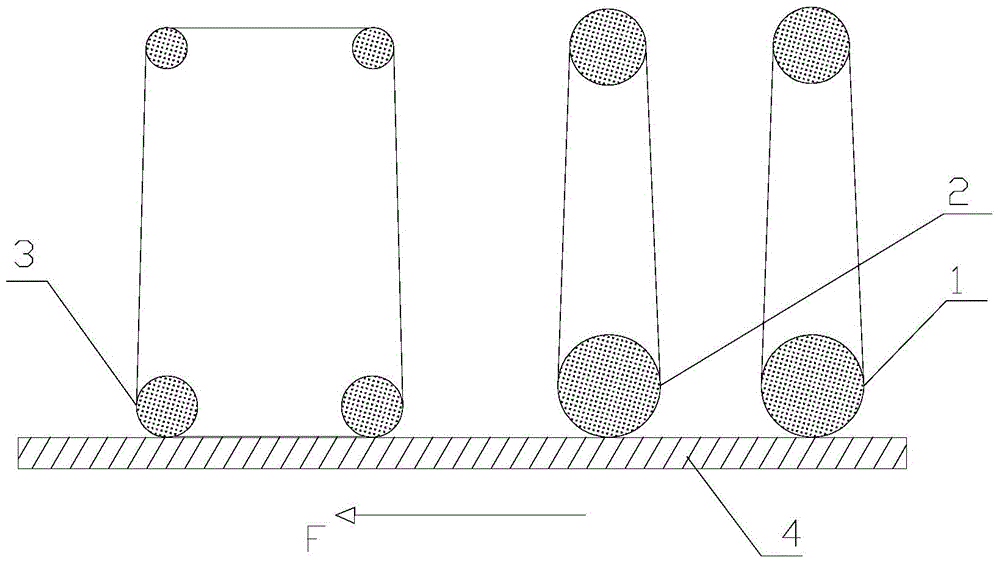

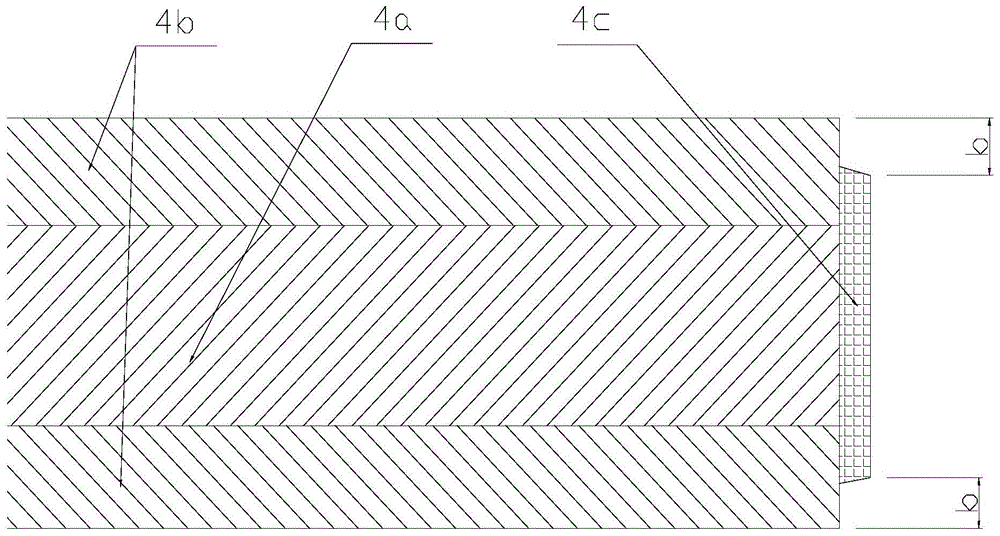

Image

Examples

Embodiment Construction

[0071] The present invention is further described below by embodiment, and present embodiment is only used for further description of the present invention, but can not be interpreted as the limitation of protection scope of the present invention, those skilled in the art makes some non-essential claims according to the content of the present invention Improvements and adjustments also belong to the protection scope of the present invention.

[0072] The technical proposal proposed by the method completely solves the defects or deficiencies of the above-mentioned process. Proceed as follows:

[0073] 1. Use plain HDF, MDF or particle board (wooden veneer) as the substrate on the upper and lower sides of the wooden door. Substrate thickness 5mm~12mm, density 780—860Kg / m 3 ;Substrate format size 2440mmX1220mm (the thickness of the veneer attached to the surface of the veneer substrate is 0.30-0.80mm);

[0074] 2. Saw and cut the substrate (HDF, MDF or particle board) and soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com