Production method of hirsutella sinensis bacterial powder

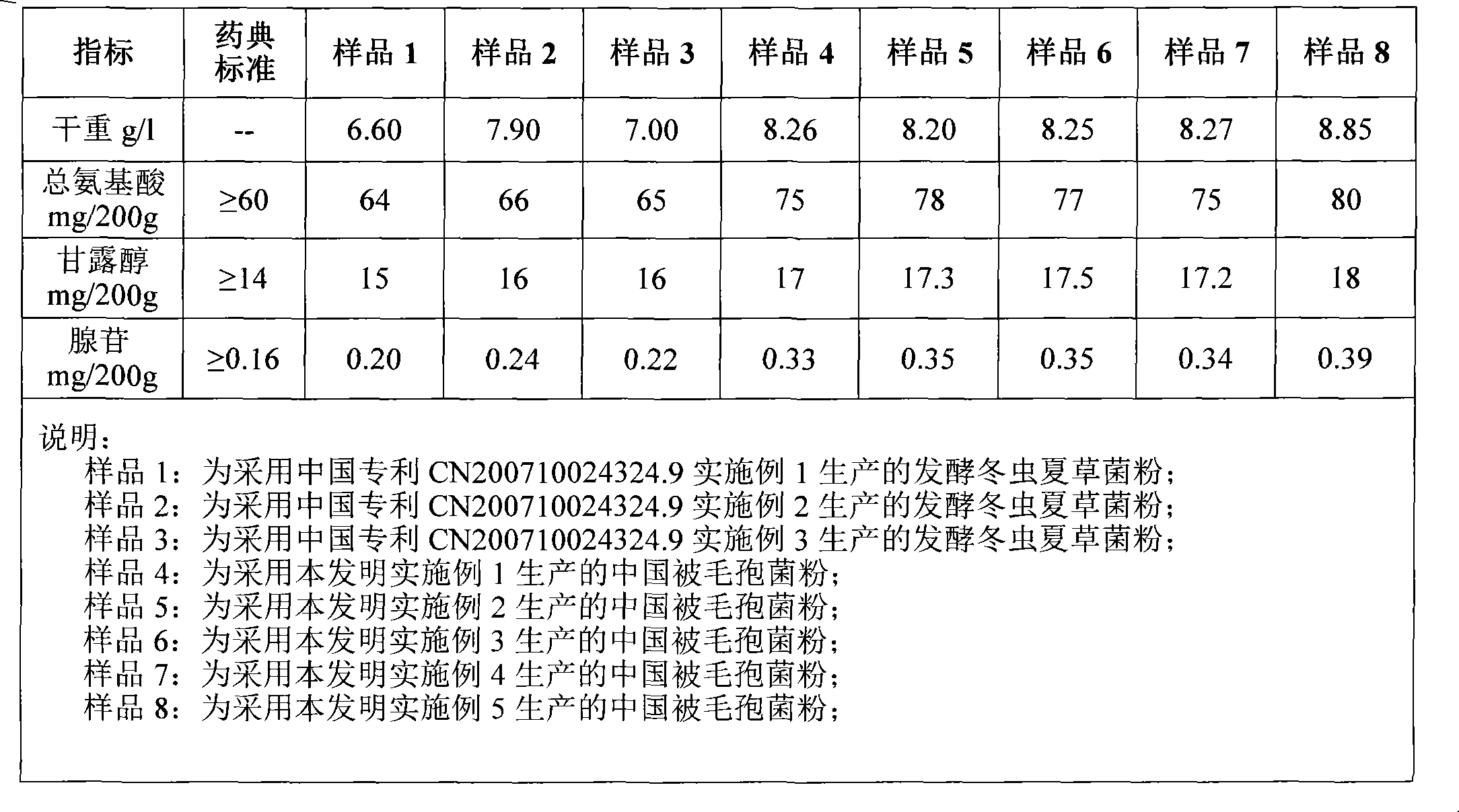

A Chinese Mortierella production method technology, applied in the production field of Chinese Mortierella powder, can solve the problems of high price, low dry matter yield, low mannitol and adenosine content, etc., and achieve the improvement of the content of main nutrients , Wide range of raw material sources, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] First take broad bean powder 2%, glucose 5%, corn flour 1.5%, peptone 1%, agar 0.75%, bran 0.5%, magnesium sulfate 0.05%, dipotassium hydrogen phosphate 0.1%, Water 89.1% makes the slant culture medium, and after receiving Mortierella sinensis strain, ferment for 30 days at 13 DEG C, then the strain is inoculated in broad bean powder 2%, glucose 2.5%, corn flour by weight volume ratio (g / ml) 1%, peptone 2%, yeast extract 5%, magnesium sulfate 0.05%, dipotassium hydrogen phosphate 1%, water 86.95% on a medium shaker, fermented at 17°C for 7 days, and then inoculated in the first-level seed tank, the medium According to weight volume ratio (g / ml), glucose 2%, yeast extract 0.5%, peptone 1%, magnesium sulfate 0.1%, dipotassium hydrogen phosphate 0.8%, water 95.6%, fermented at 13°C for 9 days, and then transferred to a container Fermented at 13 DEG C for 9 days in the secondary fermentation tank of the same level of fermentation medium, and then transferred to a container ...

Embodiment 2

[0022] First take broad bean powder 3%, glucose 4%, corn flour 1%, peptone 0.5%, agar 1%, bran 4%, magnesium sulfate 0.1%, dipotassium hydrogen phosphate 0.05%, Water 86.35% makes slant culture medium, and connects Mortierella sinensis strain 17 ℃ of fermentations for 20 days, then inoculates bacterial classification in by weight volume ratio (g / ml) with broad bean powder 3%, glucose 4%, corn flour 4%, 0.5% peptone, 1% yeast extract, 0.1% magnesium sulfate, 0.05% dipotassium hydrogen phosphate, and 87.35% water on a medium shaker, fermented at 13°C for 9 days, and then inoculated in the first-level seed tank. According to weight volume ratio (g / ml), glucose 3%, yeast extract 4%, peptone 0.5%, magnesium sulfate 1%, dipotassium hydrogen phosphate 1%, water 90.5%, fermented at 17°C for 7 days, and then transferred to a container 17 DEG C of fermenting 7 days in the secondary fermentor of same level fermentation medium, transfer to again containing broad bean powder 3%, glucose 4%...

Embodiment 3

[0024]First take broad bean powder 4%, glucose 2.5%, corn flour 4%, peptone 2%, agar 0.5%, bran 1%, magnesium sulfate 0.8%, dipotassium hydrogen phosphate 1%, Water 84.2% makes the slant culture medium, and after connecting the Mortierella sinensis strain, ferment for 22 days at 15°C, then the bacterial strain is inoculated in the weight-volume ratio (g / ml) with broad bean flour 4%, glucose 5%, corn flour 3%, peptone 1%, yeast extract 2%, magnesium sulfate 0.9%, dipotassium hydrogen phosphate 0.2%, water 83.9% on a medium shaker, fermented at 14°C for 8 days, and then inoculated in the first-level seed tank, the medium According to weight volume ratio (g / ml), glucose 4%, yeast extract 3%, peptone 1.5%, magnesium sulfate 0.05%, dipotassium hydrogen phosphate 0.1%, water 91.35%, fermented at 15°C for 8 days, and then transferred to a container 15 DEG C of fermenting 8 days in the secondary fermenter of same grade fermentation medium, transfer to again containing broad bean flour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com