Mesoporous silica and preparation method thereof

A mesoporous silica and silicon dioxide technology, applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the problems of complex synthesis process, large particle size, and small specific surface area, and achieve simple synthesis process and equipment Easy, gentle results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

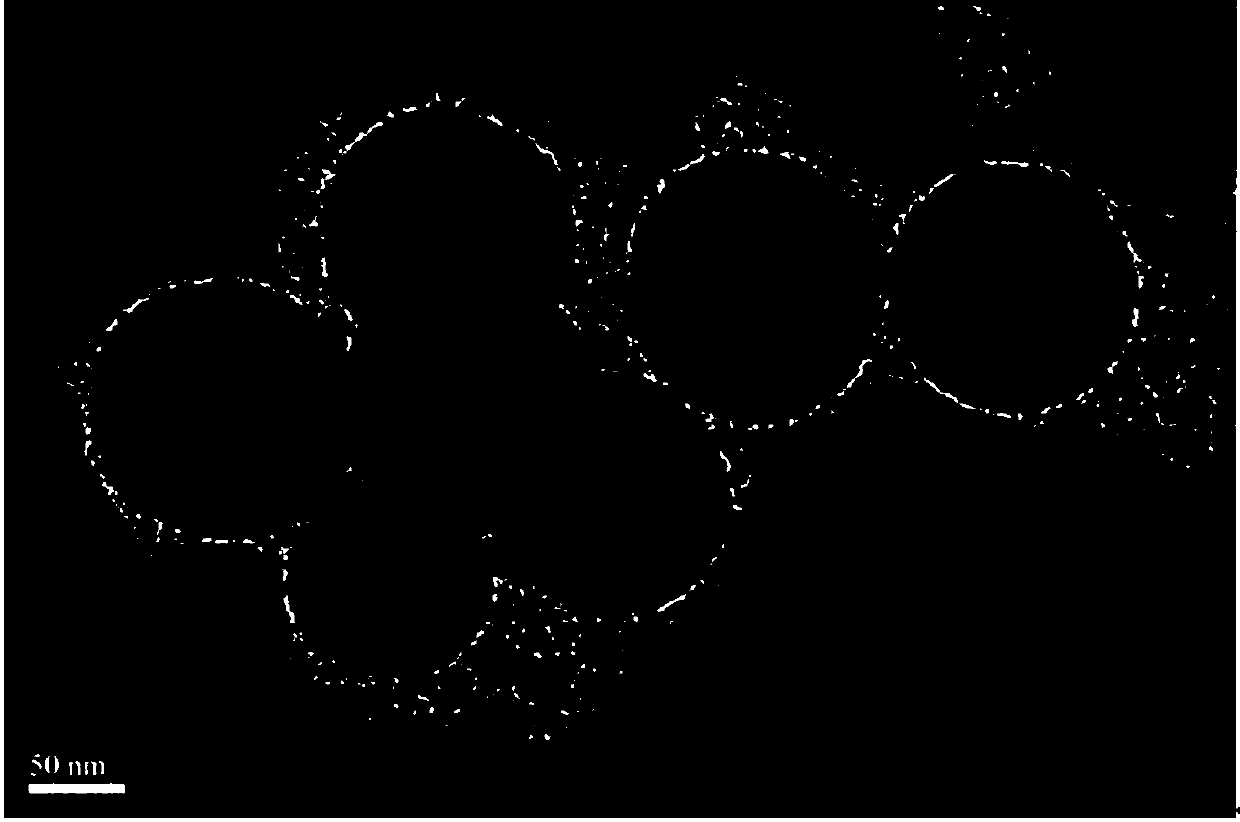

Embodiment 1

[0021] (1) Weigh 0.3g cetylammonium bromide and 0.2g polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123), add 20mL deionized water, and stir for 30 Minutes to make it fully dissolve to form a white solution; add 0.85mL concentrated ammonia to 20mL deionized water and 20mL absolute ethanol to form a mixed solution of ammonia-water-ethanol;

[0022] (2) Mix the above two solutions, after stirring for 30 minutes, slowly add 2.5 mL of tetraethyl orthosilicate, and continue to stir at room temperature for 4 hours to obtain a white silica emulsion; then stop stirring and age it For 10 hours, and dry in an oven;

[0023] (3) Put the dried silica powder in a muffle furnace at 550°C for heat treatment for 3 hours to obtain mesoporous silica nanosphere powder.

Embodiment 2

[0025] (1) Weigh 0.55g cetylammonium bromide, add 20mL deionized water, stir for 30 minutes, make it fully dissolved to form a white solution; add 0.85mL concentrated ammonia to 25mL deionized water and 25mL absolute ethanol , Configured as a mixed solution of ammonia-water-ethanol;

[0026] (2) Mix the above two solutions, stir for 30 minutes, slowly add 2.5 mL of tetraethyl orthosilicate, continue to stir at room temperature for 4 hours to obtain a silica white emulsion; then stop stirring and age it For 10 hours, and dry in an oven;

[0027] (3) Place the dried silica powder in a muffle furnace at 550°C for heat treatment for 3 hours to obtain mesoporous silica nanosphere powder.

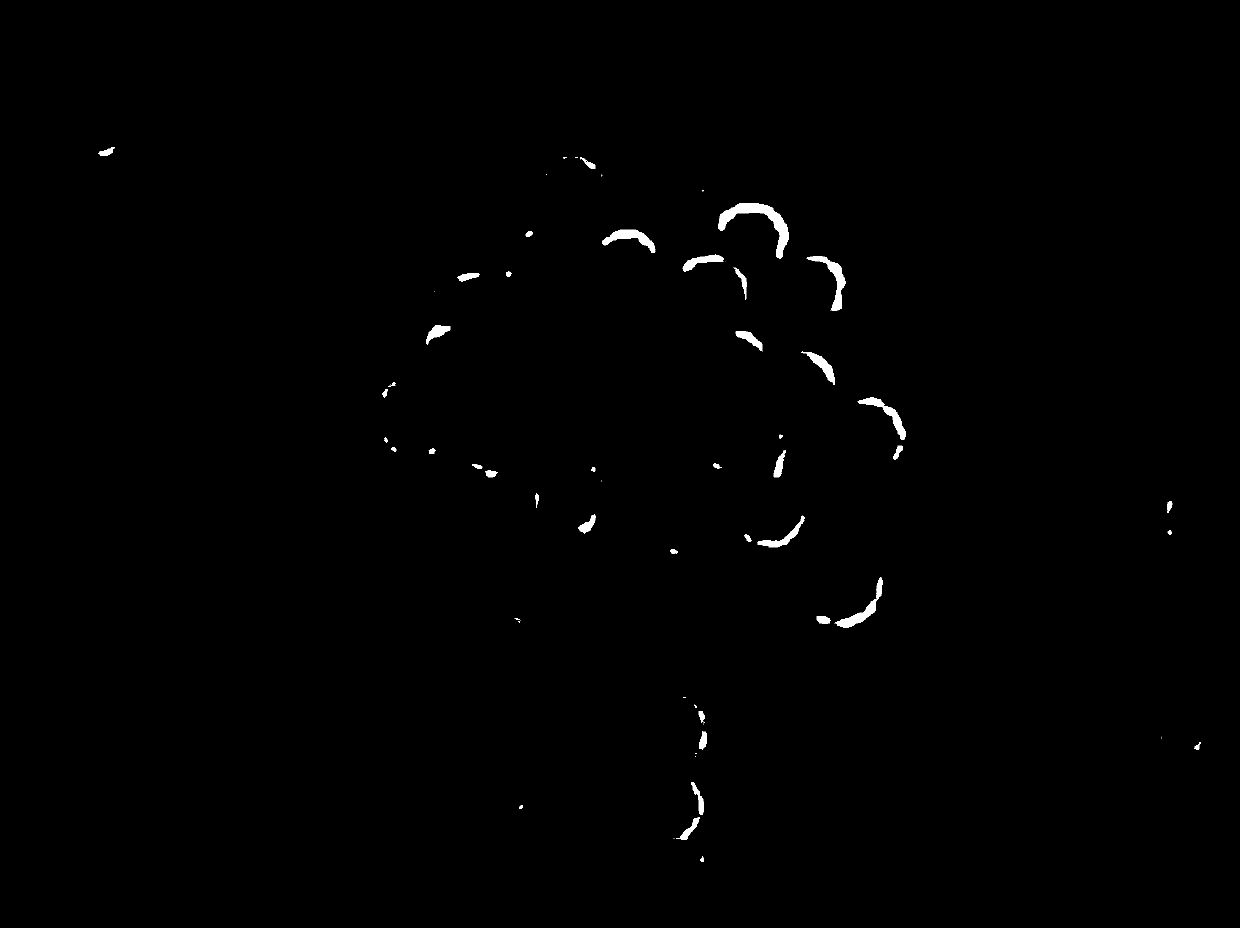

Embodiment 3

[0029] (1) Weigh 0.8g cetylammonium bromide, add 25mL deionized water, stir for 30 minutes to make it fully dissolved to form a white solution; add 1mL concentrated ammonia to 30mL deionized water and 30mL absolute ethanol, Configured as a mixed solution of ammonia-water-ethanol;

[0030] (2) Mix the above two solutions, after stirring for 30 minutes, slowly add 2.5 mL of tetraethyl orthosilicate, and continue to stir at room temperature for 4 hours to obtain a white silica emulsion; then stop stirring and age it For 10 hours, and dry in an oven;

[0031] (3) Place the dried silica powder in a muffle furnace at 550°C for heat treatment for 3 hours to obtain mesoporous silica nanosphere powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com