Ultraviolet curable coating for hardening treatment of plastic surfaces and preparation method of ultraviolet curable coating

A technology of curing coatings and hardening treatment, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as harm to the health of construction workers, increase of system viscosity, particle dispersion and system compatibility, shrinkage and warpage of coating materials, etc. problem, to achieve the effect of fast curing rate, excellent abrasion resistance and large degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

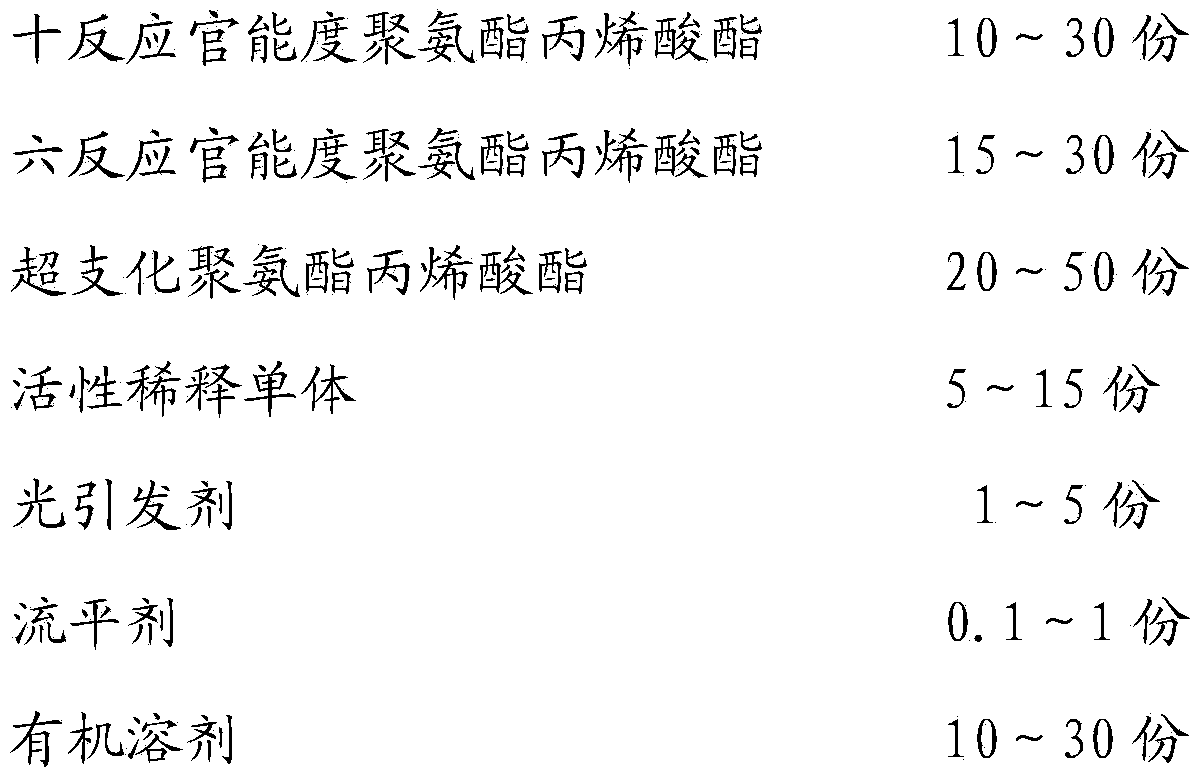

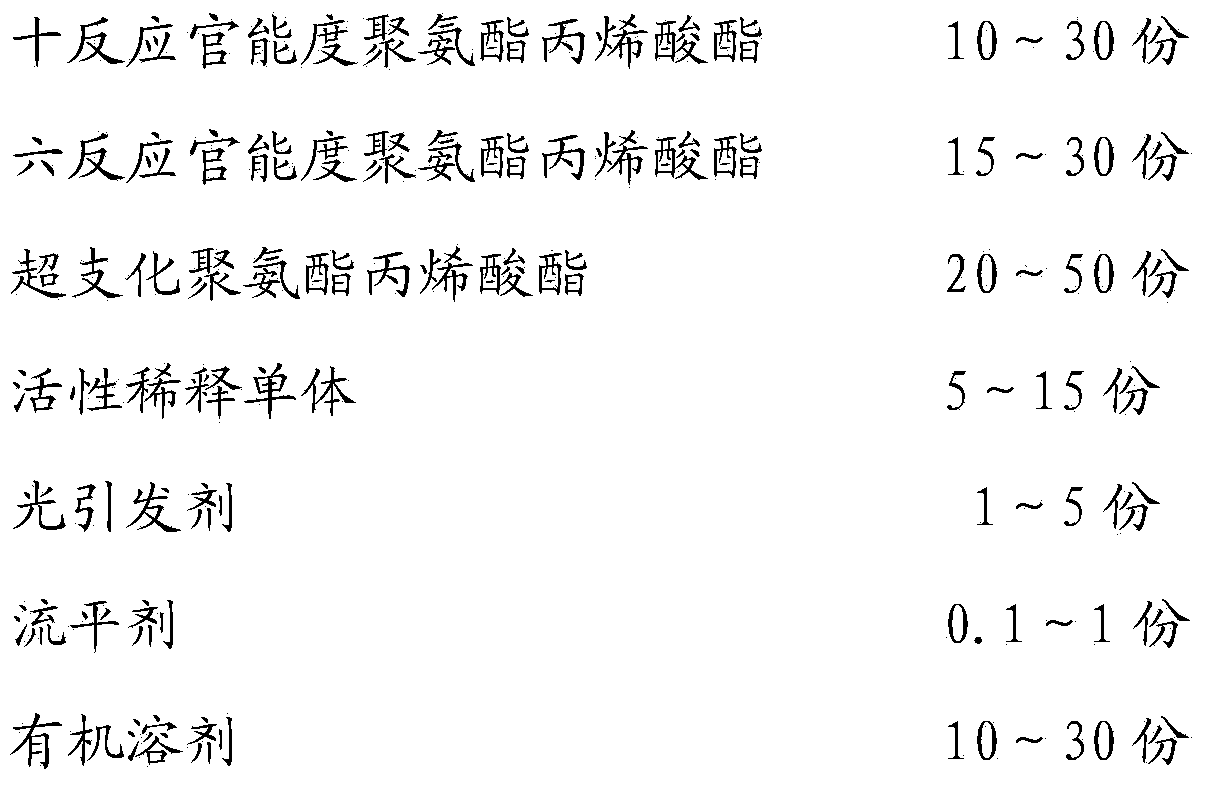

Method used

Image

Examples

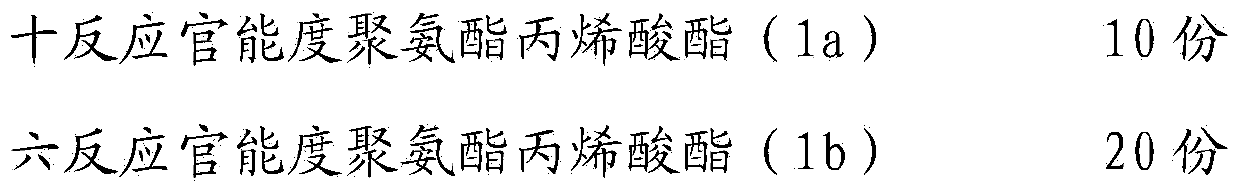

Embodiment 1

[0043] After dehydrating 100 parts by mass of polyethylene oxide diol with a molecular weight of 1500 under reduced pressure at 110-120°C for 3 hours, the temperature was lowered to 60°C, and 30 parts by mass of diphenylmethane diisocyanate and 0.04 parts by mass of octanoic acid sulfide were added under a nitrogen atmosphere. Tin, react at 60°C for 3h, then add 60 parts by mass of dipentaerythritol pentaacrylate, 10 parts by mass of acetone and 0.1 part by mass of hydroquinone monomethyl ether, react at 60°C for 2h. After the reaction is completed, the acetone is removed under reduced pressure to obtain ten-reactive functional polyurethane acrylate (1a).

[0044] After 100 parts by mass of polycaprolactone diol with a molecular weight of 500 was dehydrated under reduced pressure at 110-120°C for 3 hours, the temperature was lowered to 70°C, and 58 parts by mass of 1,3,3-trimethyl-5- Isocyanato-1-isocyanatomethylcyclohexane and 0.05 parts by mass of dibutyltin dilaurate were r...

Embodiment 2

[0051] After 100 parts by mass of polyoxytetramethylene glycol with a molecular weight of 2000 was dehydrated under reduced pressure at 110-120°C for 3 hours, the temperature was lowered to 70°C, and 20 parts by mass of 1,3,3-trimethyl- 5-isocyanato-1-isocyanatomethylcyclohexane and 0.03 parts by mass of dibutyltin dilaurate were reacted at 70°C for 4h, then 42 parts by mass of dipentaerythritol pentaacrylate, 10 parts by mass of acetone and 0.1 parts by mass of hydroquinone monomethyl ether was reacted at 80°C for 2 hours. After the reaction is completed, the acetone is removed under reduced pressure to obtain ten-reactive functional polyurethane acrylate (2a).

[0052] After dehydrating 100 parts by mass of polybutylene adipate diol with a molecular weight of 1000 under reduced pressure at 110-120°C for 3 hours, the temperature was lowered to 70°C, and 37 parts by mass of dicyclohexylmethane-4,4 '-Diisocyanate and 0.04 parts by mass of dibutyltin dilaurate were reacted at 7...

Embodiment 3

[0058] After dehydrating 100 parts by mass of polyneopentyl glycol adipate diol with a molecular weight of 500 under reduced pressure at 110-120°C for 3 hours, the temperature was lowered to 80°C, and 47 parts by mass of 1,6-hexamethylene was added under a nitrogen atmosphere. Diisocyanate and 0.04 parts by mass of stannous octoate were reacted at 80°C for 3 hours, then 84 parts by mass of dipentaerythritol pentaacrylate, 10 parts by mass of acetone and 0.2 parts by mass of hydroquinone monomethyl ether were added and reacted at 70°C for 4 hours. After the reaction is completed, the acetone is removed under reduced pressure to obtain a ten-reactive functional polyurethane acrylate (3a).

[0059] After dehydrating 100 parts by mass of polycaprolactone diol with a molecular weight of 1500 under reduced pressure at 110-120°C for 3 hours, the temperature was lowered to 60°C, and 21 parts by mass of toluene diisocyanate and 0.03 parts by mass of dibutyltin dilaurate were added under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com