A method for preparing a high-density, large-size, high-uniformity molybdenum-titanium alloy target

A technology of molybdenum-titanium alloy and large size, which is applied in the preparation of high-uniformity molybdenum-titanium alloy target material, high density, and large size field, which can solve the problems of target surface composition segregation, sputtering deposition layer performance degradation, deformation, etc. Achieve the effect of improving density uniformity, uniform microstructure and improving target quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method for preparing a high-density, large-size, high-uniformity molybdenum-titanium alloy target described in this embodiment includes the following steps,

[0033] (1) Select Mo powder with a purity of 99.96wt% and a Fischer particle size of 3 μm and titanium powder with a purity of 99.9wt% and a particle size of -325 mesh as raw materials; weigh a certain amount of Mo powder and Ti powder, add the polyethylene glycol that is equivalent to Mo powder and Ti powder weight and 3% wherein, add ethanol simultaneously, the ethanol weight that adds accounts for 30% of slurry gross weight, forms a mixture, and this mixture adopts roller ball mill Grinding for 36 hours, the ball-to-material ratio is 2:1 to form a slurry;

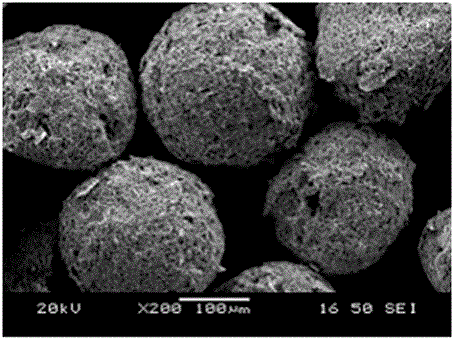

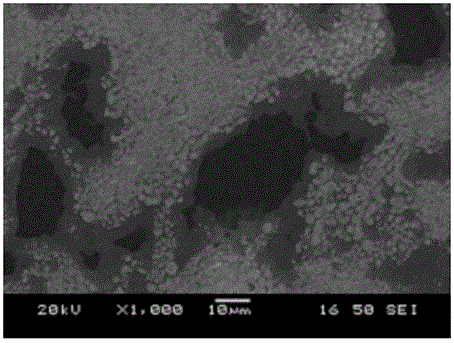

[0034](2) Spray and granulate the slurry with a closed cycle spray dryer, the inlet temperature of the spray dryer is 300°C, and the nozzle speed of the spray dryer is 8000rpm to obtain Mo-Ti composite powder;

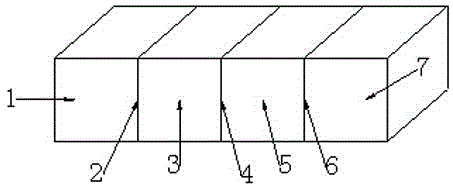

[0035] (3) The Mo-Ti composite powder is ...

Embodiment 2

[0038] The method for preparing a high-density, large-size, high-uniformity molybdenum-titanium alloy target described in this embodiment includes the following steps,

[0039] (1) Select Mo powder with a purity of 99.96wt% and a Fischer particle size of 3 μm and titanium powder with a purity of 99.9wt% and a particle size of -325 mesh as raw materials; weigh a certain amount of Mo powder and Ti powder, add the paraffin wax that is equivalent to Mo powder and Ti powder weight and 1% therein, add hexane simultaneously, the weight that adds hexane accounts for 60% of slurry gross weight, forms a mixture, and this mixture adopts roller type ball mill to grind After 36 hours, the grinding balls are Mo balls, and the ball-to-material ratio is 2:1 to form a slurry;

[0040] (2) Spray and granulate the slurry with a closed-cycle spray dryer, the inlet temperature of the spray dryer is 250°C, and the nozzle speed of the spray dryer is 12000rpm to obtain Mo-Ti composite powder filled w...

Embodiment 3

[0044] The method for preparing a high-density, large-size, high-uniformity molybdenum-titanium alloy target described in this embodiment includes the following steps,

[0045] (1) Select Mo powder with a purity of 99.96wt% and a Fischer particle size of 3 μm and titanium powder with a purity of 99.9wt% and a particle size of -325 mesh as raw materials; weigh a certain amount of Mo powder and Ti powder, add the polyethylene glycol that is equivalent to Mo powder and Ti powder weight and 2% wherein, add ethanol simultaneously, the weight that adds ethanol accounts for 50% of slurry gross weight, forms a mixture, and this mixture adopts roller type ball mill Grinding for 48 hours, the grinding balls are Mo balls, and the ball-to-material ratio is 2:1 to form a slurry;

[0046] (2) Spray and granulate the slurry with a closed-cycle spray dryer, the inlet temperature of the spray dryer is 280°C, and the nozzle speed of the spray dryer is 10000rpm to obtain Mo-Ti composite powder f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com