Preparation method of tin-dioxide-coated carbon fiber material, and product and application thereof

A technology of carbon fiber material and tin dioxide, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of high production cost, achieve the effects of low price, favorable electron transmission, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

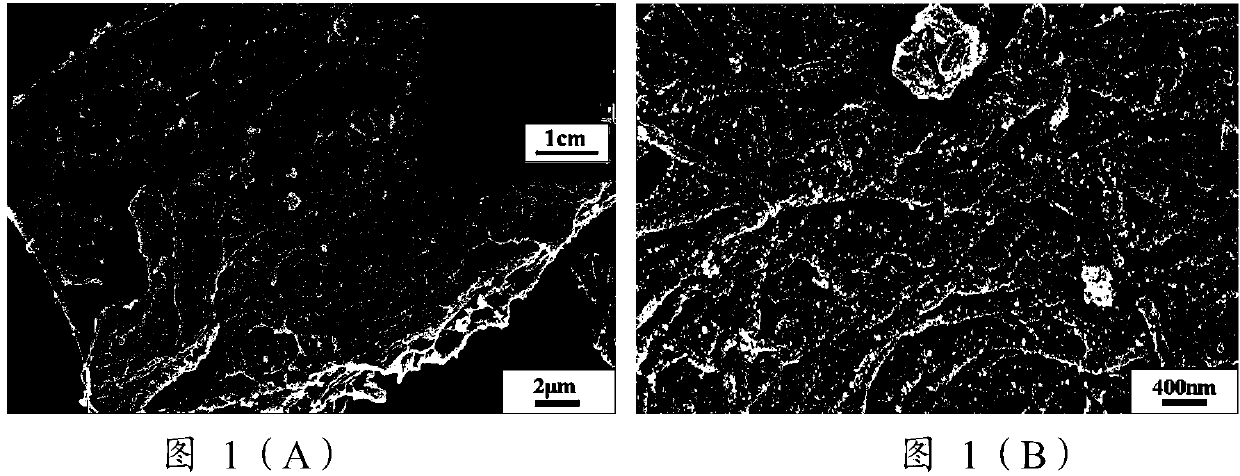

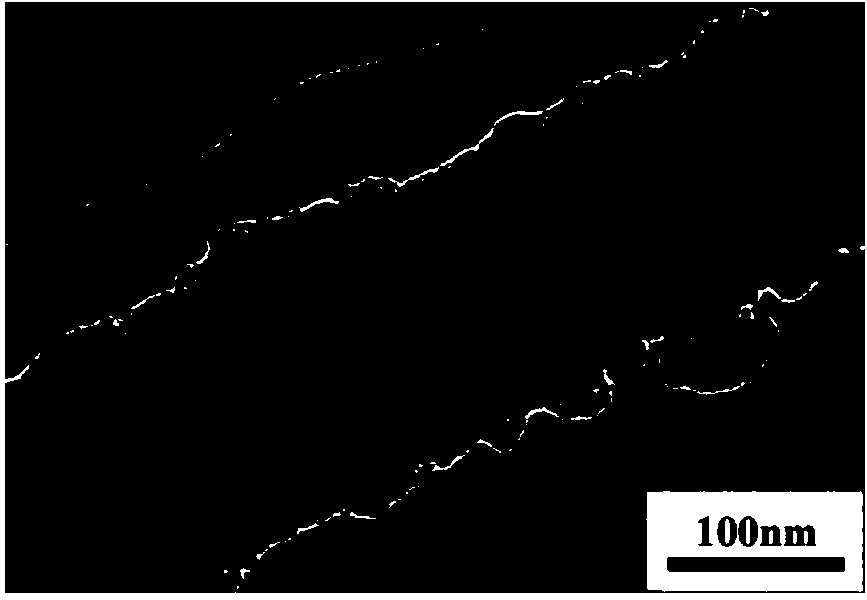

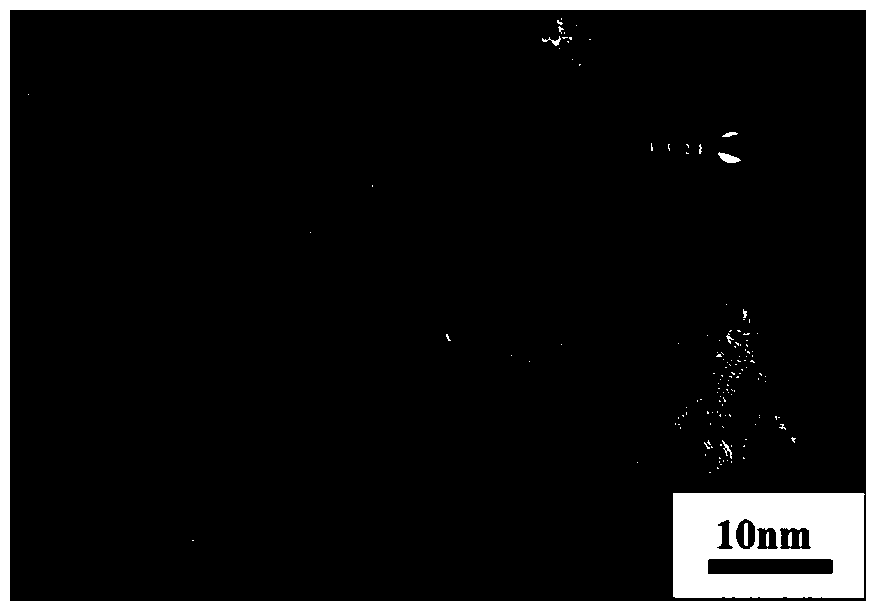

Image

Examples

Embodiment

[0040] (1) Using isopropanol and methanol with a volume ratio of 1:1 as solvents, prepare tetraisopropyl stannate solution with a concentration of 10mM, stir at room temperature for 1 hour, and heat to 50°C.

[0041] (2) Put the quantitative filter paper commonly used in the laboratory in the suction filtration device, wash the filter paper with ethanol for 3 times, and vacuum dry it.

[0042] (3) Wrap the suction filtration device in a heating belt and keep the temperature of the device at 50°C.

[0043] (4) Add 20mL of the tetraisopropyl stannate solution prepared in step (1) to the suction filtration device in step (3), and filter half of the solution with suction to soak the natural cellulose, and keep the liquid level higher than the natural fiber at all times The surface of the element, let it stand for 3 minutes, this is the deposition process.

[0044] (5) Filter the isopropyl stannate solution with low vacuum until the liquid level is slightly higher than the surface...

Embodiment 1

[0050] Step (7) in Example 1 was changed to calcining at 500° C. in air for 6 hours, and the rest were the same as in Example 1. The natural cellulose as a template is removed by air calcination, and the obtained tin dioxide nanotube material is obtained.

[0051] The transmission electron micrograph of the tin dioxide nanotube material that comparative example prepares is as Figure 4 As shown, compared with the tin dioxide-wrapped carbon fiber material prepared in the example, the nanoparticle size of the tin dioxide nanotubes prepared in the comparative example is larger, and the particle size distribution is not uniform enough.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com