Method for determining content of silicon and zirconium in silicozirconium alloy

A silicon-zirconium alloy and determination method technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of difficult observation of end points, titration interference, and unsatisfactory effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

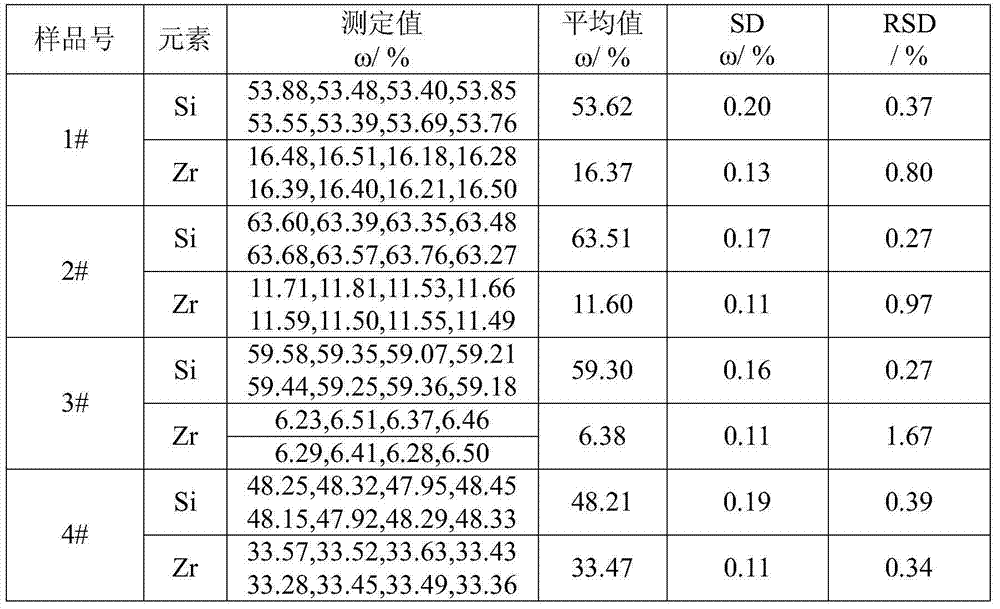

[0018] Preferred embodiments of the present invention are described in detail below.

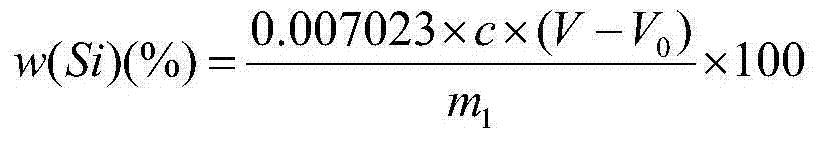

[0019] A. Determination of silicon

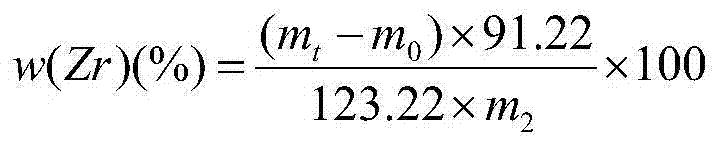

[0020] Weigh 0.2g (accurate to 0.1mg) of a sample with a particle size of less than 100 mesh into a 250mL beaker, add 20mL of 1+4 sulfuric acid, heat to dissolve, add 10mL of nitric acid to oxidize, evaporate until sulfuric acid fumes are emitted, and then remove it (the fuming time is long Easy to splash), after cooling down slightly, add 20mL of 1+1 hydrochloric acid to dissolve salts, dilute to about 100mL with hot water (above 80°C), filter with slow filter paper, wash silicic acid into the funnel with 10% hot hydrochloric acid, wipe Clean the silicic acid on the wall of the cup, wash it for 4 to 5 times, transfer the precipitate together with the filter paper into a polytetrafluoroethylene beaker, add 20mL of nitric acid, slowly add 10mL of hydrofluoric acid while stirring, smash the filter paper, and add 30mL saturated potassium nitrate solution, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com