Wide ultraviolet light absorption Fega hollow sphere nano-array material and preparation method thereof

A nano-array and hollow sphere technology is applied in the preparation of FeGa hollow sphere nano-array materials, and the field of FeGa hollow sphere nano-array materials can solve problems such as limiting the application range of metal photonic crystals, and achieve high mechanical strength, good ductility, and application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the FeGa hollow sphere nano-array material capable of regulating and controlling the broad ultraviolet light absorption performance by a magnetic field of the present invention comprises the following steps:

[0045] The first step is to clean the substrate;

[0046] The cleaning steps of the glass substrate are as follows:

[0047] Step 1. Ultrasonic cleaning of the substrate in acetone for 40 minutes, and then cleaning with distilled water several times;

[0048] Step 2. Ultrasonic cleaning of the substrate in ethanol for 40 minutes, and then cleaning with distilled water several times;

[0049] Step 3: Put the substrate in distilled water and ultrasonically clean it for 30 minutes;

[0050] Step 4. Place the substrate in a mixture of concentrated sulfuric acid and hydrogen peroxide (concentrated sulfuric acid and H 2 o 2 The volume ratio is 3:1) for 8 hours, then ultrasonic cleaning for 60 minutes, and then repeated cleaning with distill...

Embodiment 1

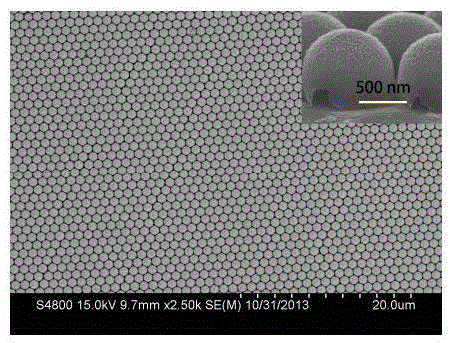

[0072] Synthesis of FeGa hollow sphere array membrane with a diameter of 1 micron:

[0073] 1. Take 10 microliters of polystyrene colloidal spheres with a diameter of 1 micron and mix them with 10 microliters of absolute ethanol solution. Synthesize the colloidal crystal template by using the air-liquid interface synthesis method in a petri dish, and scoop it up with a silicon chip. Absorb excess water with filter paper;

[0074] 2. Put the colloidal crystal template in the vacuum chamber for sputter coating, and vacuum to 10 -5 Pa, into high-purity argon to maintain 6 mtorr, sputtering power 70 watts, pre-sputtering 1000 seconds, sputtering 5000 seconds;

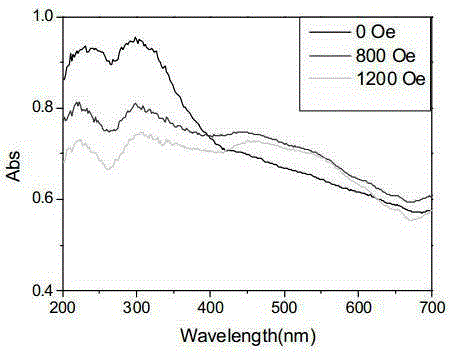

[0075] 3. Take the sample out and immerse it in dichloromethane for 1 minute, and then immerse it in acetone for 1 minute to obtain a shape as follows: figure 1 As shown, the UV light absorption properties are as image 3 shown.

Embodiment 2

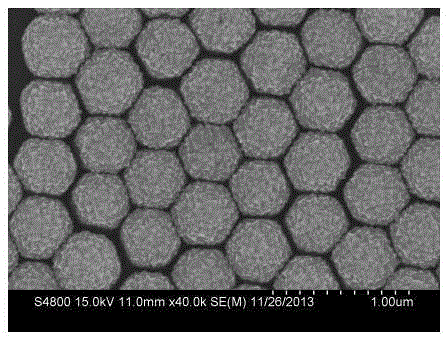

[0077] Synthesis of FeGa hollow sphere array membrane with a diameter of 500nm:

[0078] 1. Mix 10 microliters of polystyrene colloidal spheres with a diameter of 500nm and absolute ethanol at a ratio of 1:1, synthesize a colloidal crystal template in a petri dish by gas-liquid interface synthesis, and scoop it up with a silicon wafer;

[0079] 2. Put the colloidal crystal template in the vacuum chamber for sputter coating, and vacuum to 10 -5 Pa, into the argon gas to maintain 6 mtorr, sputtering power 70 watts, pre-sputtering 1000 seconds, sputtering 1500 seconds;

[0080] 3. Take the sample out and immerse it in dichloromethane for 1 minute, and then immerse it in acetone for 1 minute to obtain a shape as follows: figure 2 As shown, the UV light absorption properties are as Figure 4 shown.

[0081] The prepared sample has strong ultraviolet absorption in the ultraviolet, especially in the range of 200-400 nanometers. In addition, the UV absorption coefficient can be a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com