Method for removing arsenic from yellow phosphorus through oxidation

A yellow phosphorus and oxidant technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high production cost, long process flow of arsenic removal, poor safety performance, etc., and achieve good economic and social benefits, The effect of increasing the solid-liquid contact surface and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

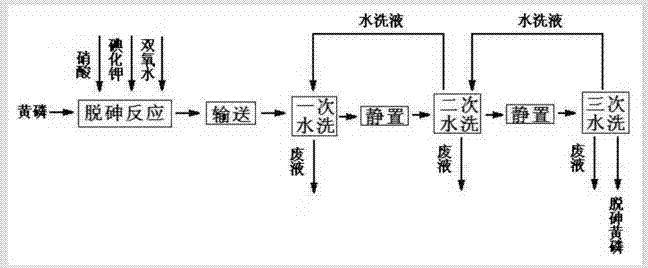

Image

Examples

Embodiment 1

[0032] A method for removing arsenic by oxidation of yellow phosphorus. Under normal pressure, a nitric acid solution with a mass concentration of 5-25% is prepared as a basic oxidant, and the yellow phosphorus and nitric acid solution are put into a reaction kettle at a weight ratio of 1:1-5 and stirred , mix evenly, heat and keep the temperature at 65~80°C. Add the oxidation catalyst potassium iodide solution with a mass concentration of 5-25% after stirring and mixing the yellow phosphorus and the basic oxidant nitric acid solution for 10-60 minutes, and the oxidation catalyst potassium iodide solution is 1-5% of the mass of the yellow phosphorus. After adding the oxidation catalyst potassium iodide solution, add an oxidation enhancer hydrogen peroxide solution with a mass concentration of hydrogen peroxide effective content of 10 to 30% to the reaction kettle every 40 to 60 minutes, and the oxidation enhancer hydrogen peroxide solution is 5 to 20% of the mass of yellow phos...

Embodiment 2

[0035] A method for removing arsenic by oxidation of yellow phosphorus. Under normal pressure, a nitric acid solution with a mass concentration of 10% is prepared as a basic oxidant, and the yellow phosphorus and the nitric acid solution are put into a reactor in a weight ratio of 1:2 to stir and mix evenly. Heat and maintain the temperature at 70°C. After stirring and mixing the yellow phosphorus and the basic oxidant nitric acid solution for 40 minutes, add the oxidation catalyst potassium iodide solution with a mass concentration of 10%, and the oxidation catalyst potassium iodide solution is 2% of the yellow phosphorus mass. After adding the oxidation catalyst potassium iodide solution, add an oxidation enhancer hydrogen peroxide solution with a mass concentration of 10% of the effective content of hydrogen peroxide to the reactor every 40 minutes. The oxidation enhancer hydrogen peroxide solution is 5% of the mass of yellow phosphorus, and add it in 4 times.

[0036] Afte...

Embodiment 3

[0038] A method for removing arsenic by oxidation of yellow phosphorus. Under normal pressure, a nitric acid solution with a mass concentration of 15% is prepared as a basic oxidant, and the yellow phosphorus and the nitric acid solution are put into a reactor in a weight ratio of 1:3 to stir and mix evenly. Heat and maintain the temperature at 75°C. After stirring and mixing the yellow phosphorus and the basic oxidant nitric acid solution for 30 minutes, add the oxidation catalyst potassium iodide solution with a mass concentration of 15%, and the oxidation catalyst potassium iodide solution is 3% of the yellow phosphorus mass. After adding the oxidation catalyst potassium iodide solution, add an oxidation enhancer hydrogen peroxide solution with a mass concentration of 15% of the effective content of hydrogen peroxide to the reactor every 45 minutes. The oxidation enhancer hydrogen peroxide solution is 15% of the mass of yellow phosphorus, and is added in three times.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com