Preparation method of low-cost ZSM-5 type zeolite molecular sieve, and application thereof

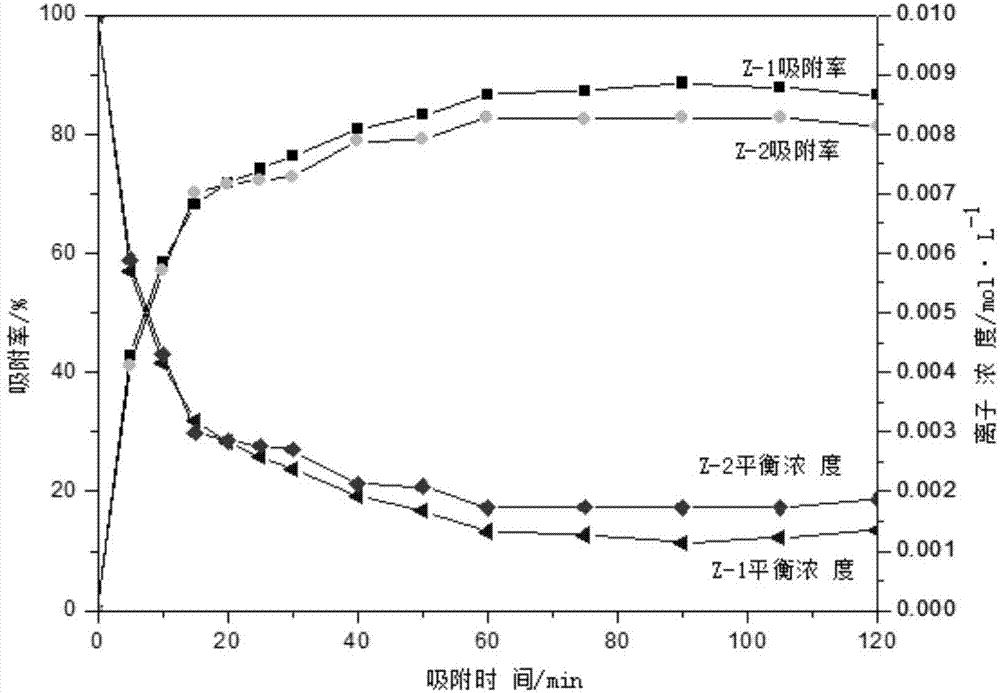

A technology of zeolite molecular sieve and ZSM-5, which is applied in chemical instruments and methods, crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminum silicate zeolite, etc., can solve the problem of high preparation cost, achieve convenient operation, reduce The effect of synthesis cost and good adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

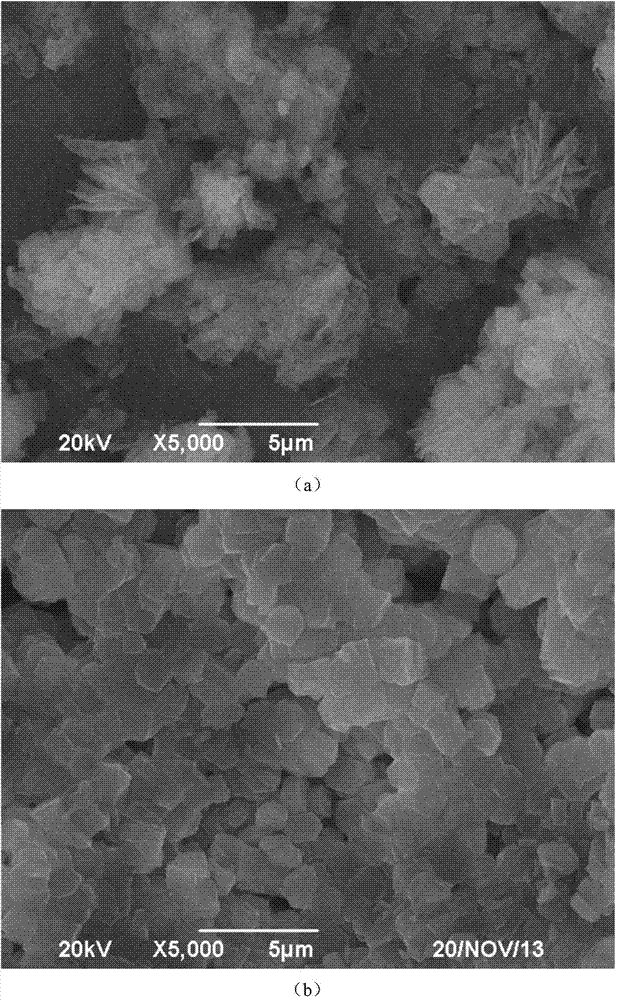

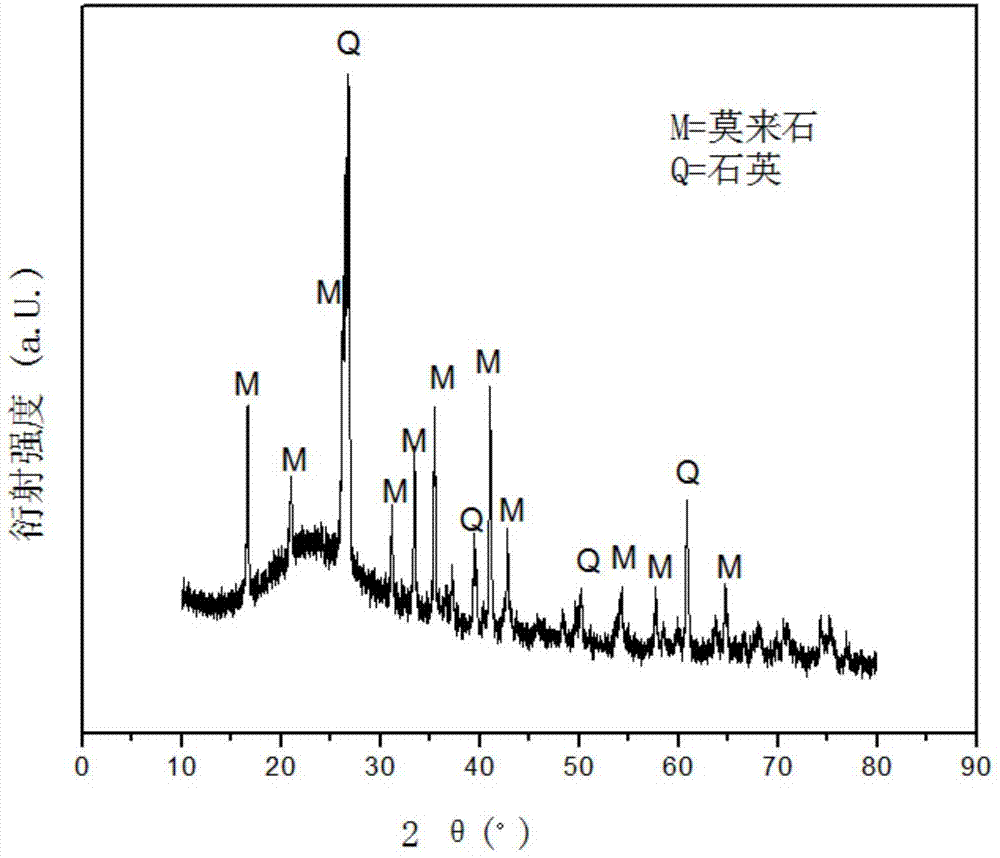

[0029] With reference to the accompanying drawings, this embodiment of a low-cost ZSM-5 type zeolite molecular sieve preparation method, the fly ash used is from a thermal power plant in Huainan, the XRD ray diffraction pattern of the raw fly ash powder is shown figure 2 . The main mineral crystal phases of fly ash raw powder are quartz and mullite, as well as amorphous glass phase components. The main chemical components are analyzed by X-ray fluorescence spectrometer (XRF) in Table 1. It can be seen from Table 1 that Fe, Ca and other metal impurities in the fly ash used in this embodiment account for a part of the proportion, but the content of Si and Al is relatively high, especially with a relatively high Si / Al ratio. Silicon source and aluminum source have high comprehensive utilization value.

[0030] Table 1 The main chemical composition of fly ash (wt%)

[0031]

[0032] The chemical reagents used in this example are tetrapropylammonium hydroxide (TPAOH), NH 4 F, NaOH, H...

Embodiment 2

[0042] The preparation method of a low-cost ZSM-5 zeolite molecular sieve in this example is basically the same as that in Example 1. The preparation steps are briefly described as follows:

[0043] Dry the raw fly ash at 140°C for 20 hours to constant weight, mix the dry fly ash and the HCl solution with a mass percentage concentration of 10% at a solid-liquid ratio (g / mL) of 1:20, and stir thoroughly Centrifuge for 10 minutes at 5000 rpm for 30 min. After removing the supernatant, wash with deionized water to a pH of 6, and dry at 100°C for use.

[0044] Accurately weigh 20g of iron-removing fly ash and 44g of NaOH, grind uniformly to 400 mesh, then place it in a muffle furnace to melt for 3 hours at 500°C, after cooling, grind through a 200-mesh sieve, and then grind the resulting molten material. Add it to the deionized water at the ratio of solid-liquid mass ratio of 1:4, mix it into a slurry, and stir in a water bath at 80℃ for 24h to make the aluminosilicate in the fly ash i...

Embodiment 3

[0047] The preparation method of a low-cost ZSM-5 zeolite molecular sieve in this example is basically the same as that in Example 1. The preparation steps are briefly described as follows:

[0048] Dry the raw fly ash powder at 125°C for 22 hours to constant weight, mix the dry fly ash and HCl solution with a mass percentage concentration of 10% at a solid-liquid ratio (g / mL) of 1:20, and stir thoroughly Centrifuge for 13 minutes at 5000 rpm for 25 minutes, remove the supernatant, wash with deionized water to pH=7, and dry at 100°C for use.

[0049] Accurately weigh the iron-removing fly ash and NaOH according to the mass ratio m(SiO 2 ):m(NaOH)=1:2.2 ratio, grind uniformly to 200 mesh, then place it in a muffle furnace to melt at 450℃ for 4h. After cooling, grind through a 200-mesh sieve. The solid-liquid mass ratio of 1:3 is added to the deionized water, mixed into a slurry, and stirred in a water bath at 80℃ for 24 hours to make the aluminosilicate in the fly ash in OH - Dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com