Fungicidal composition containing azoxystrobin and tebuconazole and application of fungicidal composition

A composition, the technology of azoxystrobin, which is applied in the field of preparation of pesticide fungicidal composition, can solve the problems of increased environmental pressure, increased cost, and increased dosage, so as to save economic cost, reduce energy consumption, and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

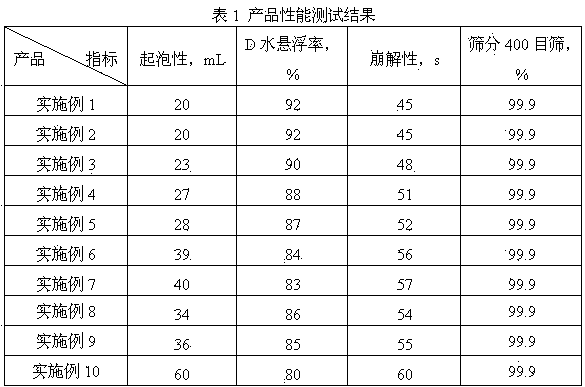

[0041] Example 1 85% Azoxystrobin Tebuconazole Water Dispersible Granules

[0042] Azoxystrobin 49%, tebuconazole 36%, foliar fertilizer potassium chloride 1.807%, diammonium hydrogen phosphate 3.197%, ammonium nitrate 1.946%, chelated iron 0.05%, dispersant sodium polycarboxylate 2.5%, alkyl Sodium phenolsulfonate 1.0%, calcium lignosulfonate 1.0%, wetting agent a-sulfo fatty acid methyl ester 0.5%, sodium a-olefin sulfonate 0.5%, fatty amide N-methyl taurine sodium salt 0.5% 100% of cornstarch, after the mixture is fully mixed, it is pulverized by ultra-fine airflow to obtain a 750-mesh fine powder, and then the resulting fine powder is kneaded by adding an appropriate amount of water in a kneader, and granulated by a rotary granulator. Dry at 50°C in a fluidized fluidized bed to obtain 85% azoxystrobin tebuconazole water dispersible granules.

Embodiment 2

[0043] Example 2 52% Azoxystrobin Tebuconazole Water Dispersible Granules

[0044] Azoxystrobin 30%, tebuconazole 22%, foliar fertilizer potassium chloride 1.807%, diammonium hydrogen phosphate 3.197%, ammonium nitrate 1.946%, chelated iron 0.05%, dispersant sodium polycarboxylate 2.5%, alkyl Sodium phenolsulfonate 1.0%, calcium lignosulfonate 1.0%, wetting agent a-sulfo fatty acid methyl ester 0.5%, sodium a-olefin sulfonate 0.5%, fatty amide N-methyl taurine sodium salt 0.5% , cornstarch make up 100%, after the mixture is fully mixed, carry out ultra-fine airflow pulverization to obtain 720 mesh fine powder, then add appropriate amount of water to the kneader to knead the obtained fine powder, and then granulate through the rotary disc granulator, Dry at 60°C in a fluidized fluidized bed to obtain 52% azoxystrobin tebuconazole water dispersible granules.

Embodiment 3

[0045] Example 3 85% Azoxystrobin Tebuconazole Water Dispersible Granules

[0046] Azoxystrobin 49%, Tebuconazole 36%, Dispersant sodium polycarboxylate 2.5%, Sodium alkylphenol sulfonate 1.0%, Calcium lignosulfonate 1.0%, Wetting agent a-sulfo fatty acid methyl ester 0.5% , 0.5% of sodium α-olefin sulfonate, 0.5% of fatty amide N-methyl taurine sodium salt, and 100% of cornstarch. After the mixture is fully mixed, it is pulverized by ultra-fine airflow to obtain a 730-mesh fine powder. The resulting fine powder is kneaded with an appropriate amount of water in a kneader, granulated by a rotary granulator, and dried in a fluidized fluidized bed at 55°C to obtain 85% azoxystrobin-tebuconazole water-dispersible granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com