Particle size control method of ceramic powder prepared by wet chemical method

A technology of ceramic powder and wet chemical method, which is applied in the field of ceramic powder preparation, can solve the problems of increasing process difficulty and preparation cost, environmental pollution, initial powder agglomeration, etc., to reduce the difficulty of preparation process and reduce production cost, Effect of Reducing Agglomerated Particle Size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This example is used to prepare CoAl 2 o 4 Blue ceramic pigment, the control method of its preparation method and particle size is as follows:

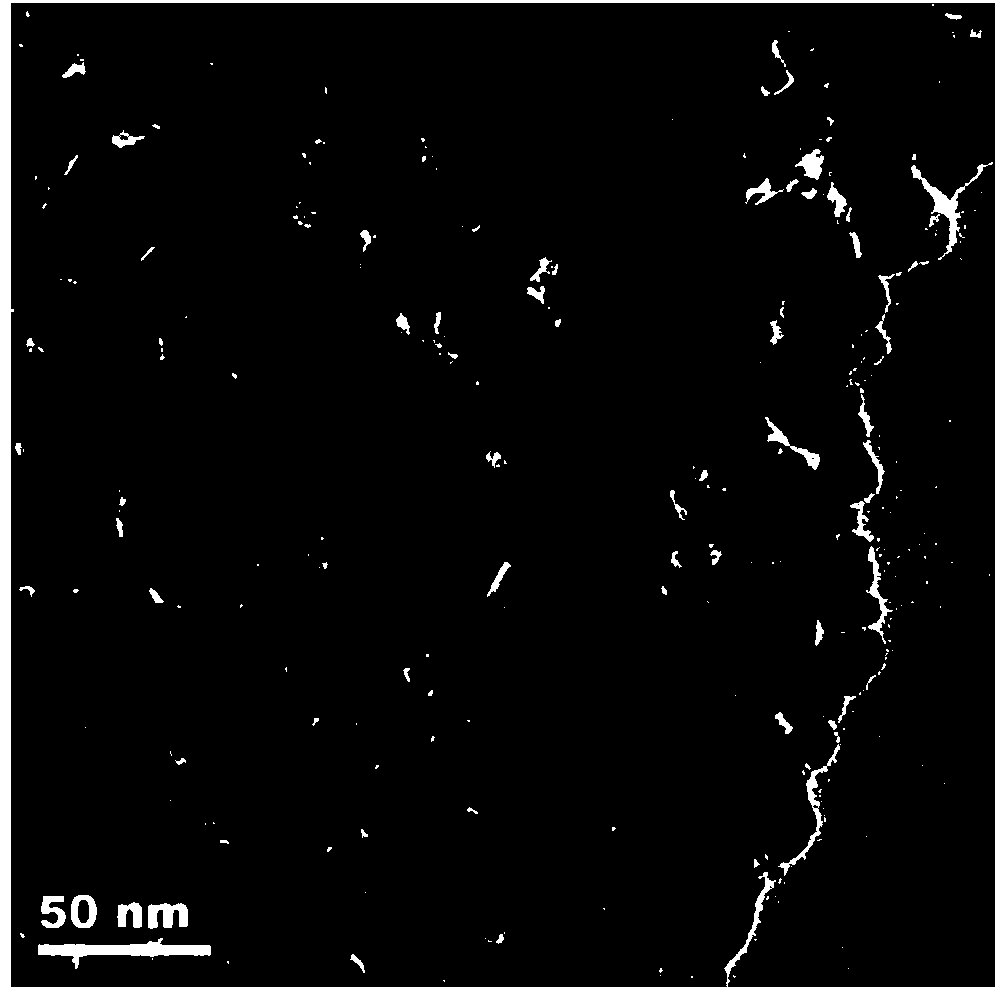

[0025] (1) Co(NO 3 ) 2 ·6H 2 O3.4926g, Al(NO 3 ) 2 9H 2 O13.5046g and 9.0084g of glycine were dissolved in 200ml of water to obtain a mixed solution. Put the mixed solution in an evaporating dish, adjust the power of the electric furnace to slowly evaporate the water in the solution, and when the solution becomes viscous and large bubbles are formed, increase the power of the electric furnace to burn the solution to obtain the initial powder. Such as figure 1 As shown, the particle size of the initial powder is about 30nm.

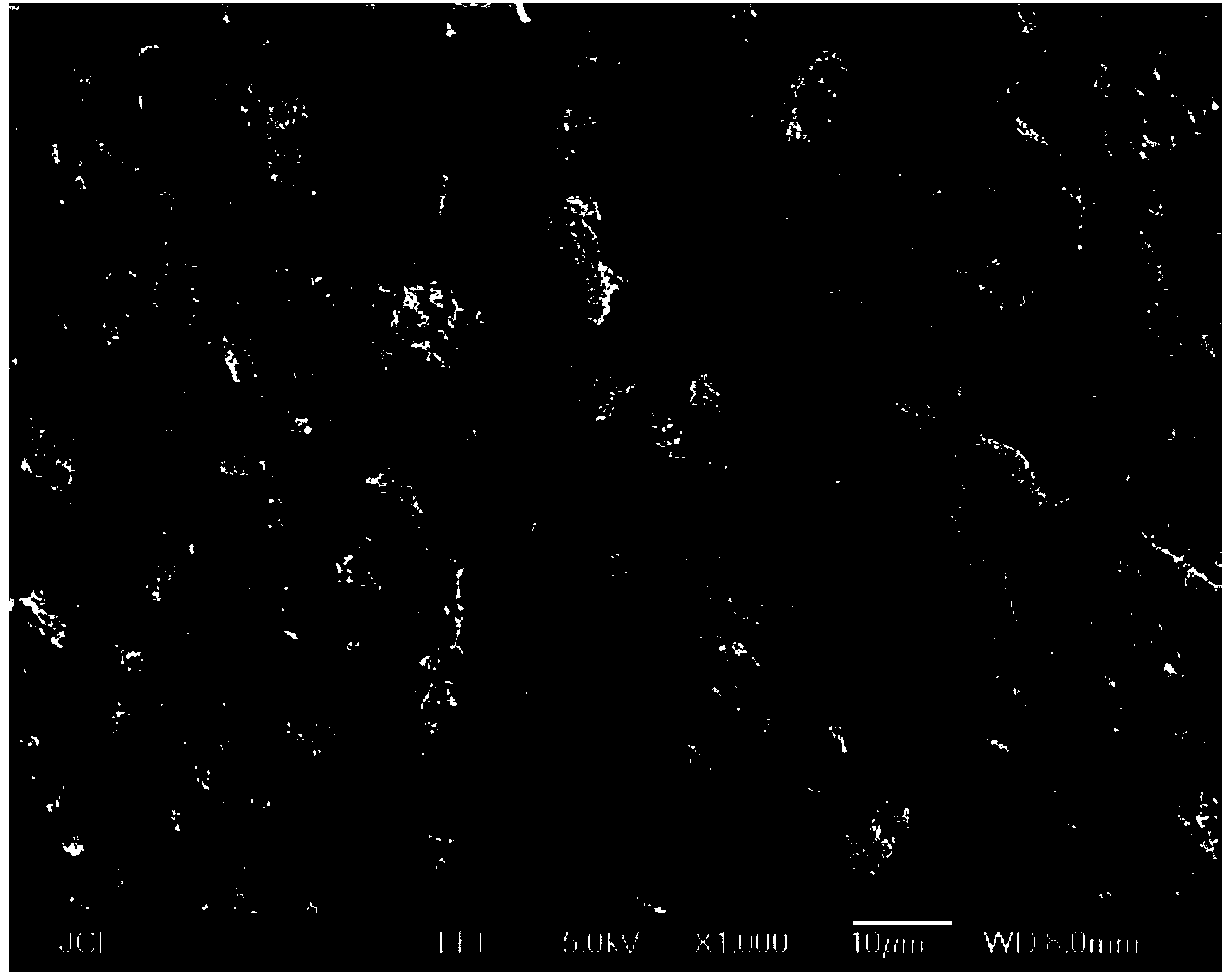

[0026] (2) Add graphite or starch to the initial powder for mixing as shown in Table 1, wherein the average particle diameter D50 of graphite is 13.1 μm, and the average particle diameter D50 of starch is 9.21 μm. Add absolute ethanol as a grinding aid, ball mill for 2 hours to mix evenly, dry in ...

Embodiment 2

[0032] This embodiment is used to prepare YAlO doped with Cr 3 Pink ceramic pigment, the control method of its preparation method and particle size is as follows:

[0033] (1) 11.4918g of yttrium nitrate, 0.12g of chromium nitrate, and 11.1414g of aluminum nitrate are dissolved in 80ml distilled water to obtain A solution; 7.507g of glycine is dissolved in 100ml of distilled water, and the pH value of the solution is adjusted with ammonia water or slightly greater than 7 and A solution of B was obtained. Slowly add solution B into solution A, and stir evenly to obtain a mixed solution. Add the mixed solution into a heat-resistant pot, and use a disc-type electric furnace with a transformer until the solution is viscous and hemispherical and bubbles into a hard shell; then increase the voltage of the transformer and heat up until the solution burns to form a light pink fluffy solid and Obtain the initial powder.

[0034] (2) Add combustible graphite or starch to the initial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com