Method for synthetizing NaA type molecular sieve membrane in seed crystal aerosol

A molecular sieve and sol technology, used in chemical instruments and methods, separation/purification of hydroxyl compounds, membrane technology, etc., can solve the problems of low yield and production capacity, difficult supports, etc., and achieve low yield and production capacity. , excellent performance, high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

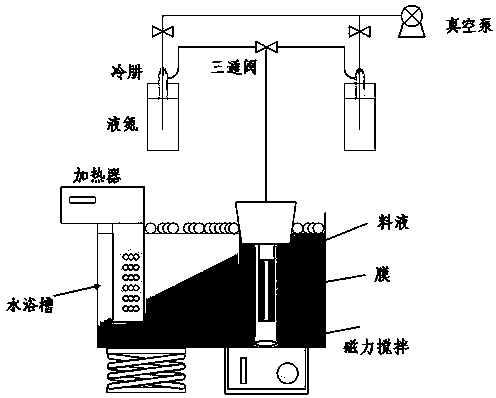

Method used

Image

Examples

Embodiment 1

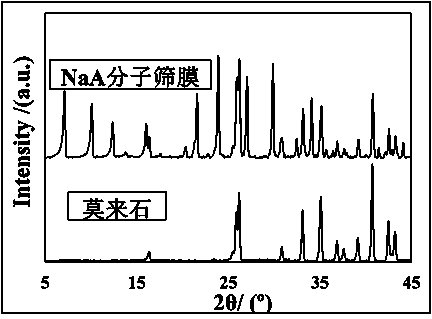

[0027] The heterogeneous SOD molecular sieve seed crystals were used to induce the synthesis of nanometer NaA molecular sieve crystals in fluorine-containing sol. Sodium silicate, aluminum hydroxide, sodium hydroxide, sodium fluoride and water are used as raw materials to prepare a composition of 1SiO 2 : 0.5Al 2 o 3 : 1Na 2 O: 40H 2 O: 1NaF sol for crystal seed synthesis, then nano SOD crystals are added in the sol for seed crystal synthesis, the addition is 2% by weight, and this synthetic stoste is at 80 o C hydrothermal synthesis in a water bath shaking condition for 6 days, centrifuged at 8000 rpm for 30 minutes, and washed 4 times to obtain ~30 nm NaA molecular sieve crystals.

[0028] The NaA molecular sieve membrane was synthesized on the porous tubular mullite support by using the seeded sol. Sodium silicate, aluminum hydroxide, sodium hydroxide, sodium fluoride and water are used as raw materials to prepare a composition of 1 SiO 2 : 0.5 Al 2 o 3 : 1 Na 2 O...

Embodiment 2

[0032] The synthetic ratio is the same as that of Preparation Step Example 1. The difference is that the amount of seed crystal added is 3 g seed crystal. The synthesized membrane was cleaned and applied to the pervaporation performance of 10 wt% water / ethanol system at 75 oC, the results are as follows Figure 11 shown.

Embodiment 3

[0034] The synthetic ratio is the same as that of Preparation Step Example 1. The difference is that the amount of seed crystal added is 0.3 g seed crystal. The synthesized membrane was cleaned and applied to the pervaporation performance of 10 wt% water / ethanol system at 75 oC, the results are as follows Figure 11 shown. Figure 5 Surface and cross-sectional microstructures of NaA-type zeolite membranes synthesized on porous mullite tubular supports are shown. The surface of the support body is covered by a few square NaA molecular sieve crystals, which cannot form a continuous molecular sieve film layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com