A method and system for treating ultra-clean sewage without sludge biospheres

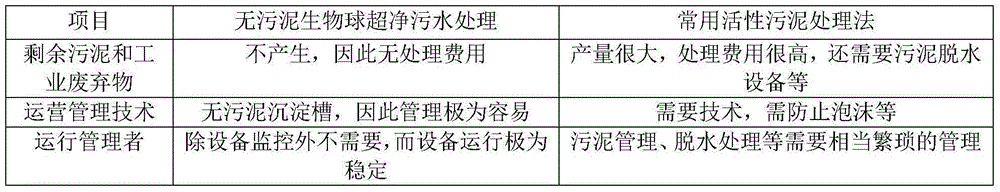

A sewage treatment method and sewage treatment system technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve the problem of harsh microbial working conditions, high operating costs, and low treatment efficiency and other issues to achieve the effect of reducing equipment cost and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

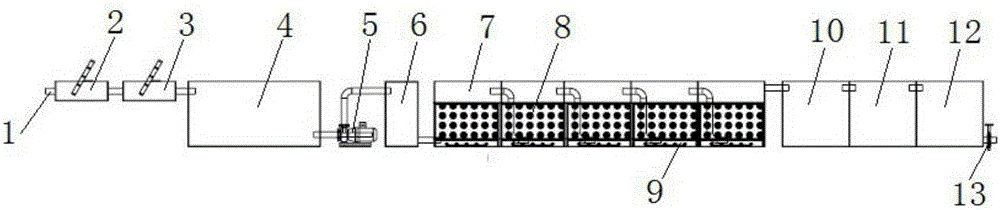

[0048] Taking domestic sewage as the treatment object, a kind of sludge-free biological ball ultra-clean sewage treatment method of the present embodiment includes the following steps:

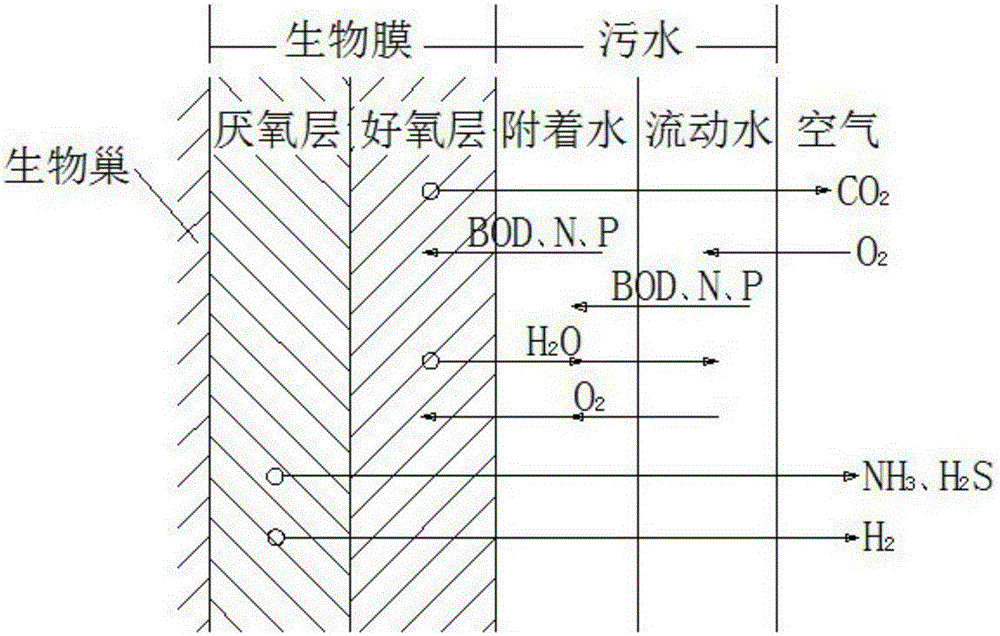

[0049] (1) Establish microbial carriers: install biological nests in bioreactor tanks, and use sand balls as biofilm fillers; set the number of bioreactor tanks and the total volume of biological nests according to the type of sewage, and set the total volume of biological nests Distributed to each biological reaction tank; Among them, the ball diameter of the sand ball is 30mm-50mm, the porosity is 60%-85%, suitable for the growth and reproduction of microorganisms on the surface, and the resistance to water flow is small, which is different from the traditional biological ceramsite In comparison, the effect of bio-film is more ideal, and the cost is greatly reduced; in the whole system of sewage treatment, the ratio of the total volume of biological nests to the total amount of sewage treatme...

Embodiment 2

[0059] Taking biopharmaceutical factory sewage as the treatment object, a kind of sludge-free biological ball ultra-clean sewage treatment method of the present embodiment includes the following steps:

[0060] (1) Establish microbial carriers: install biological nests in bioreactor tanks, and use sand balls as biofilm fillers; set the number of bioreactor tanks and the total volume of biological nests according to the type of sewage, and set the total volume of biological nests Assigned to each bioreactor tank. For biopharmaceutical factory sewage, the ratio of the total volume of the biological nest to the total amount of sewage treatment is 1:1, and there are at least 8 biological reaction tanks. With the increase in the number of biological reaction tanks, the discharged sewage is more stable; At the same time, 8 bioreactors are set up, which are divided into three parts: the front section, the middle section and the back end. Among them, the height of the biological nest ...

Embodiment 3

[0069] Taking printing and dyeing factory sewage as the treatment object, a kind of sludge-free biological ball ultra-clean sewage treatment method in this embodiment includes the following steps:

[0070] (1) Establish microbial carriers: install biological nests in bioreactor tanks, and use sand balls as biofilm fillers; set the number of bioreactor tanks and the total volume of biological nests according to the type of sewage, and set the total volume of biological nests Assigned to each bioreactor tank. For printing and dyeing factory sewage, the ratio of the total volume of biological nests to the total amount of sewage treatment is 1:1.5, and there are at least 6 biological reaction tanks. With the increase in the number of biological reaction tanks, the discharged sewage will be more stable; specifically, when installing , there are 6 bioreactors, which are divided into three parts: the front section, the middle section and the back end. Among them, the height of the bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com