High-insulation hydrolysis-preventing polyurethane filling and sealing material and preparation method thereof

A potting material and high insulation technology, which is applied in the field of high insulation and hydrolysis-resistant polyurethane potting materials and its preparation, can solve the problems of shelf life and use effect, too fast reaction speed, short operation time, etc., to achieve Excellent hydrolysis resistance, less air bubbles, excellent effect of hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

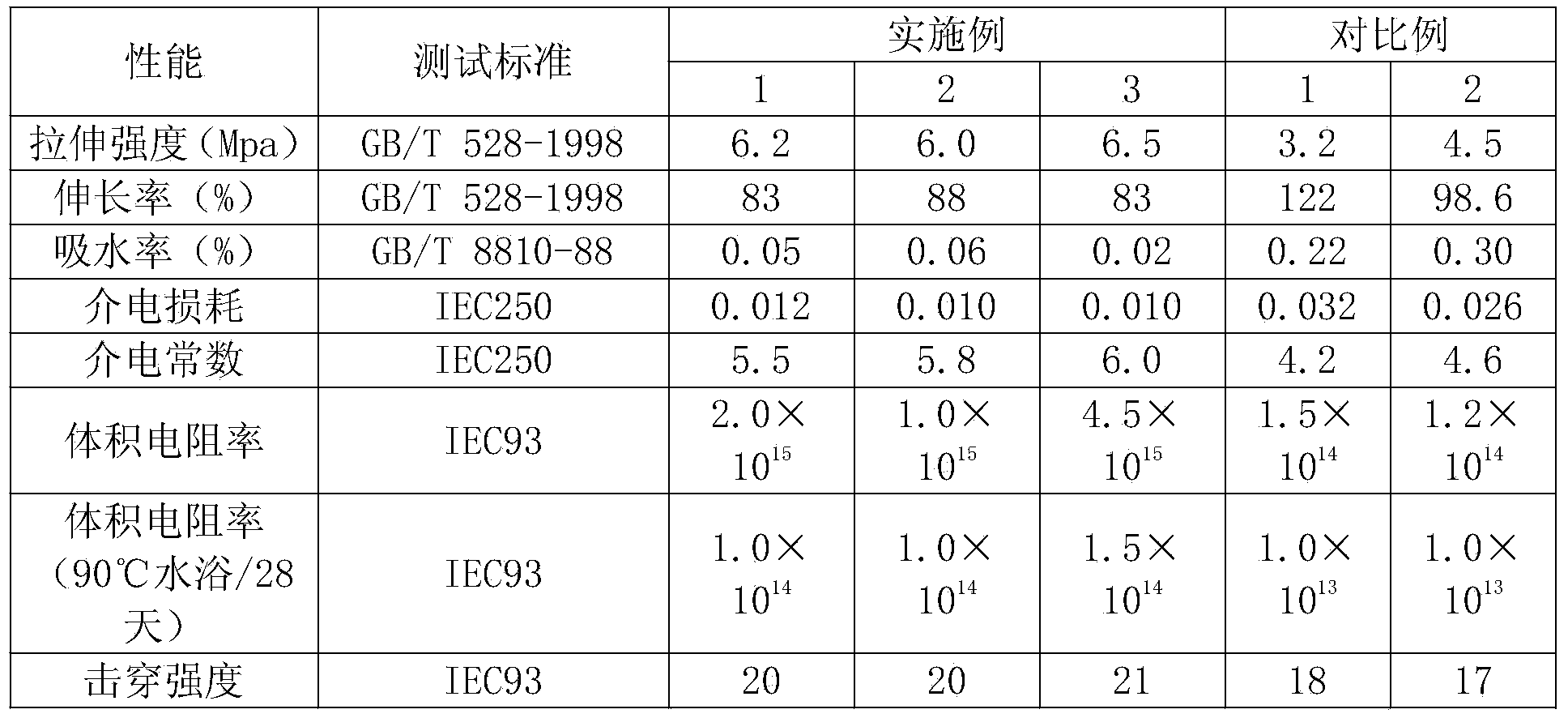

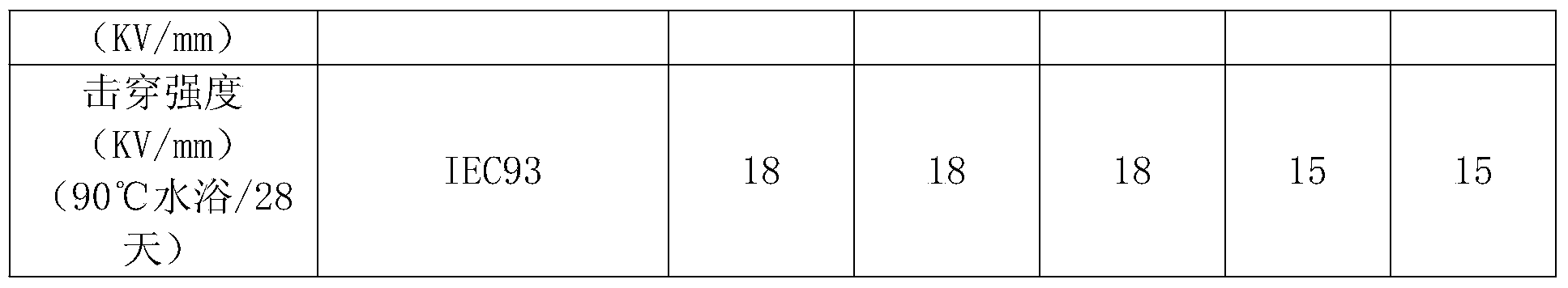

Examples

Embodiment 1

[0035] This embodiment relates to a high-insulation and hydrolysis-resistant polyurethane potting material; the polyurethane potting material is a two-component; wherein, the composition is measured by weight percentage, and component A consists of 44% castor oil, 3.5% poly Ether polyol, 1% chain extender, 7.25% desiccant, 44% filler, 0.05% catalyst, 0.1% yellow colorant, 0.1% defoamer; B component is 100% poly isocyanate.

[0036] The preparation method of the polyurethane potting material of the present embodiment is specifically as follows:

[0037]Component A: Weigh 44kg of castor oil (hydroxyl value 162mgKOH / g), 3.5kg of polyoxypropylene glycol (hydroxyl value 110mgKOH / g) and 1kg of 1,2 propylene glycol in a 150L stirred tank, and stir at 120°C for 2h , while vacuum degassing (vacuum pressure -0.1Mpa); add 0.1kg of defoamer, 0.05kg of stannous octoate and stir for 0.5h, then add 7.25kg of 4A molecular sieve, 0.1kg of yellow color paste, calcium carbonate (pre-baked at 12...

Embodiment 2

[0041] This embodiment relates to a high-insulation and hydrolysis-resistant polyurethane potting material; the polyurethane potting material is a two-component; wherein, the composition is measured by weight percentage, and component A is composed of 45.5% castor oil, 3% poly Ether polyol, 1.5% chain extender, 10% desiccant, 39.78% filler, 0.02% catalyst, 0.1% yellow colorant, 0.1% defoamer; B component is 100% poly isocyanate.

[0042] The preparation method of the polyurethane potting material of the present embodiment is specifically as follows:

[0043] Component A: Weigh 45.5kg of castor oil (hydroxyl value 162mgKOH / g), 3kg of polyoxypropylene triol (hydroxyl value 110mgKOH / g) and 1.5kg of 1,4-butanediol in a 150L stirred tank, at 120°C Stir under pressure for 1.5h, while vacuum degassing (vacuum pressure-0.1Mpa); add 0.1kg of defoamer, 0.02kg of stannous octoate and stir for 0.5h, then add 10kg of 4A molecular sieve, 0.1kg of yellow color paste, silicon micropowder (pr...

Embodiment 3

[0047] This embodiment relates to a high-insulation and hydrolysis-resistant polyurethane potting material; the polyurethane potting material is two-component; wherein, the composition is measured by weight percentage, and component A is composed of 50% castor oil, 2% poly Ether polyol, 2% chain extender, 6.5% desiccant, 39.2% filler, 0.1% catalyst, 0.1% yellow color paste, 0.1% defoamer; B component is 100% poly isocyanate.

[0048] The preparation method of the polyurethane potting material of the present embodiment is specifically as follows:

[0049] Component A: Weigh 50kg of castor oil (hydroxyl value 162mgKOH / g), 2kg of polypropylene glycol (hydroxyl value 110mgKOH / g) and 2kg of trimethylolpropane in a 150L stirred tank, stir at 120°C for 2h, and vacuum Degassing (vacuum pressure -0.1Mpa); add 0.1kg of defoamer, 0.1kg of stannous octoate and stir for 0.5h, then add 6.5kg of 4A molecular sieve, 0.1kg of yellow color paste, talcum powder (after pre-baking at 120°C for 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com