Polymer flooding crude oil demulsifier and preparation method and application thereof

A technology of crude oil demulsifier and polymer, which is applied in the direction of chemical dehydration/demulsification, etc. It can solve the problems of inability to meet the requirements of external transportation, difficult separation of oil and water, and serious emulsification of crude oil, so as to reduce the pressure of sewage treatment and efficiently demulsify Milk, the effect of increasing the molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

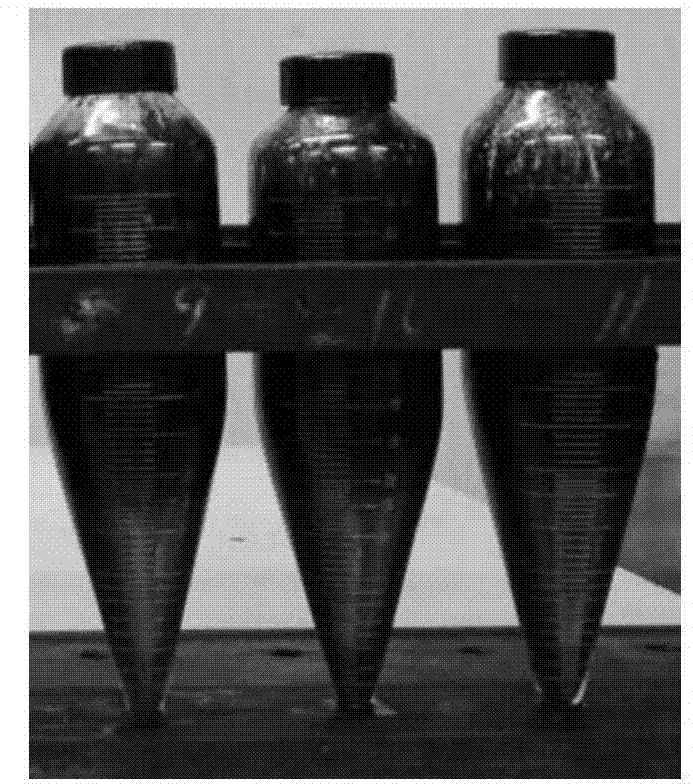

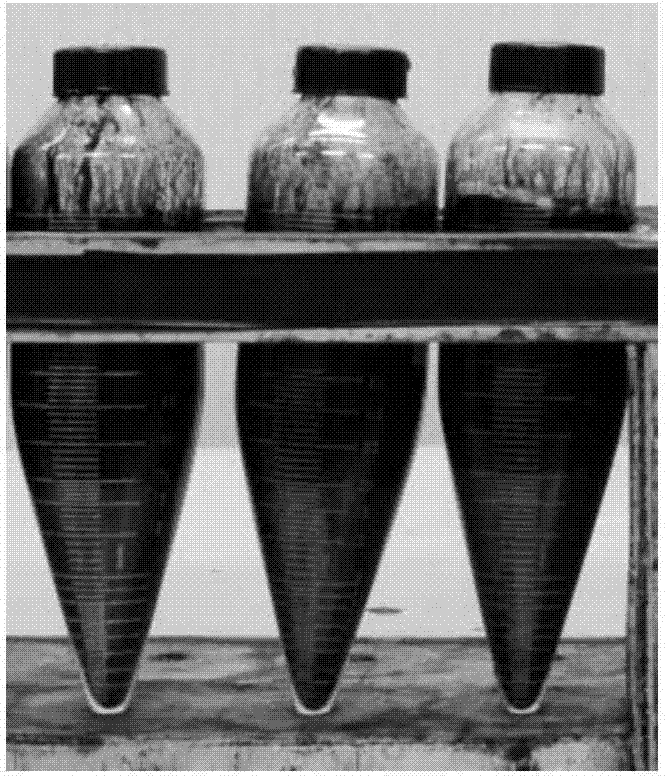

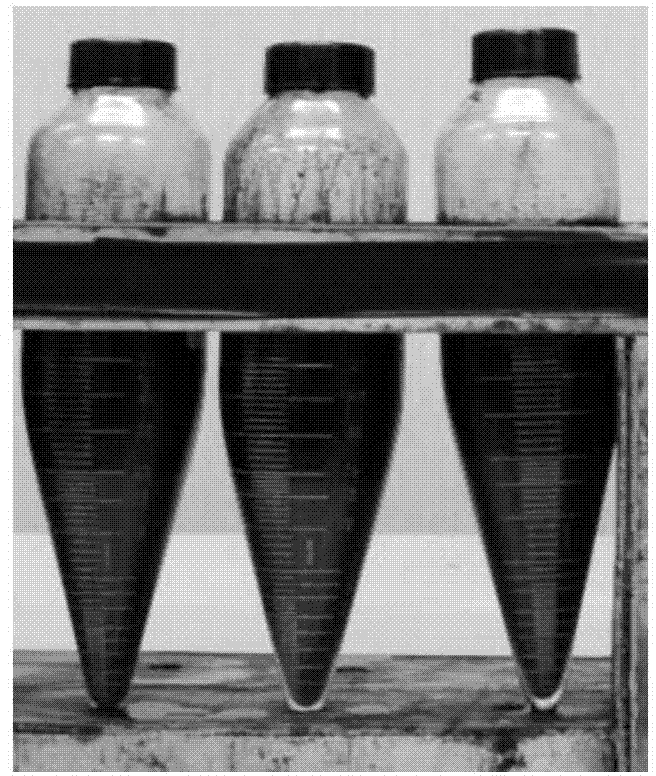

Image

Examples

Embodiment 1

[0063] The synthesis of embodiment 1, demulsifier DP-1

[0064] (1) Synthesis of α,α-bis(4-aminophenyl)-1-(3',5'-dimethyl-4'-sulfophenyl)methane

[0065] 1) Synthesis of aromatic diamines

[0066] Add 37.20g (0.40mol) of aniline and 70mL of distilled water to a three-necked flask equipped with mechanical stirring, a condenser, and a nitrogen port, and stir thoroughly under nitrogen protection. Slowly add 50.00mL concentrated hydrochloric acid (mass fraction 37%) dropwise, keep the system temperature at 40°C, then add 29.52g (0.22mol) 3,5-dimethylbenzaldehyde in batches. After the system was vigorously stirred under reflux for 12 hours, the temperature of the reaction system was lowered to 50° C., and 34.60 g of anhydrous potassium carbonate powder was added in batches under stirring until the system no longer produced bubbles. The solution was subjected to steam distillation, and a solid powder was obtained after suction filtration. Rinse the solid powder with hot water, re...

Embodiment 2

[0077] The synthesis of embodiment 2, demulsifier DP-2

[0078] (1) Synthesis of α,α-bis(4-amino-3,5-diethylphenyl)-1-(4'-methoxy-5'-sulfophenyl)methane

[0079] 1) Synthesis of aromatic diamines

[0080] Add 59.68g (0.40mol) of 2,6-diethylaniline and 120.00mL of distilled water to a three-necked flask equipped with mechanical stirring, a condenser, and a nitrogen port, and stir thoroughly under nitrogen protection. 61.50 mL of sulfuric acid solution (35% by mass) was slowly added dropwise, and the system temperature was maintained at 30°C, and then 28.56 g (0.21 mol) of 4-methoxybenzaldehyde was added in batches. After the system was vigorously stirred under reflux for 6 hours, the temperature of the reaction system was lowered to 50° C., and 36.90 g of sodium bicarbonate powder was added in batches under stirring until the system no longer produced bubbles. The solution was subjected to steam distillation, and a solid powder was obtained after suction filtration. Rinse th...

Embodiment 3

[0091] Embodiment 3, the synthesis of demulsifier DP-3

[0092] (1) α,α-bis(4-amino-3,5-dimethoxyphenyl)-1-(3',5'-dimethyl-4'-sulfophenyl)methane

[0093] 1) Synthesis of aromatic diamines

[0094] Add 61.28g (0.40mol) of 2,6-dimethoxyaniline and 135.00mL of distilled water to a three-necked flask equipped with mechanical stirring, a condenser, and a nitrogen port, and stir thoroughly under nitrogen protection. Slowly add 40.50 mL of concentrated hydrochloric acid (mass fraction 37%) dropwise, and maintain the system temperature at 35°C, then add 28.14 g (0.21 mol) of 3,5-dimethylbenzaldehyde in batches. After the system was vigorously stirred under reflux for 6 hours, the temperature of the reaction system was lowered to 50° C., and 16.40 g of sodium hydroxide powder was added in batches under stirring. The solution was subjected to steam distillation, and a solid powder was obtained after suction filtration. Rinse the solid powder with hot water, recrystallize with dioxan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com