A stabilizer composition specially used for halogen-containing rubber

A technology of stabilizer and composition, applied in the field of stabilizer composition of halogen-containing rubber, can solve the problems of increasing the volume cost of halogen-containing rubber products, increasing the proportion of rubber materials, increasing the weight of rubber products, etc., and improving the aging resistance. , the effect of improving the degree of dispersion and improving the physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] It is specially used in the stabilizer composition of halogen-containing rubber, including 60% magnesium oxide, 10% magnesium hydroxide, and 30% calcium 2-hydroxy-1,4-phthalate.

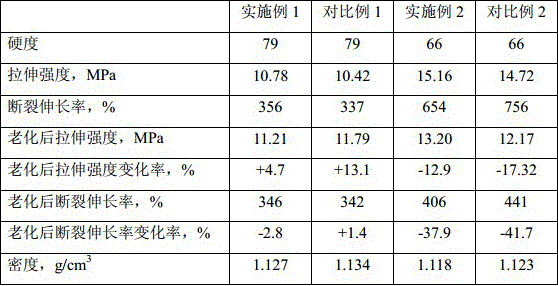

[0021] Weigh 200g of chlorinated polyethylene, 6g of vulcanizing agent DCP, 4g of cross-linking auxiliary agent TAIC, 4g of stearic acid, 4g of zinc stearate, 40g of chlorinated paraffin, 10g of epoxy soybean oil, 54g of light calcium carbonate, half supplement Mix 30g of strong carbon black, 70g of gas-mixed carbon black, and 20g of stable composition (accurate to 0.001g) in an enamel cup or stainless steel cup, and then place the mixed sample on a double stick that has been preheated to 130~140°C Kneading on a drum mill to obtain a rubber compound. Then vulcanize according to the positive curing time at (150±2)°C to obtain vulcanized rubber. Tested according to national standards, the obtained properties are shown in Table 1. Scanning electron micrographs of the tensile fracture surface ar...

Embodiment 2

[0023] It is specially used in the stabilizer composition of halogen-containing rubber, including 60% magnesium oxide, 20% magnesium salicylate, and 20% calcium 3-hydroxy-1,2-phthalate.

[0024] On the double-drum mill, pass the CR2321 neoprene several times, and then add various additives: 4 parts of stabilizer composition, 5 parts of zinc oxide, 40 parts of semi-reinforcing carbon black, DOP 5 part, 5 parts of softening oil, 1 part of stearic acid, and 1.5 parts of HVA-2 to obtain a rubber compound. Then vulcanize according to the positive curing time at (150±2)°C to obtain vulcanized rubber. Tested according to national standards, the obtained properties are shown in Table 1.

Embodiment 3

[0026] It is specially used in the stabilizer composition for halogen-containing rubber, including 40% magnesium oxide, 20% magnesium hydroxide, 30% calcium salicylate, and 10% magnesium m-hydroxybenzoate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com