Method for modifying melamine pyrophosphate fire retardant by grafting oxidized graphene

A technology of melamine pyrophosphate and melamine, applied in the field of materials, can solve the problems of large particle size, large addition, environmental pollution, etc., and achieve the effects of small impact on mechanical properties, small particle size and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

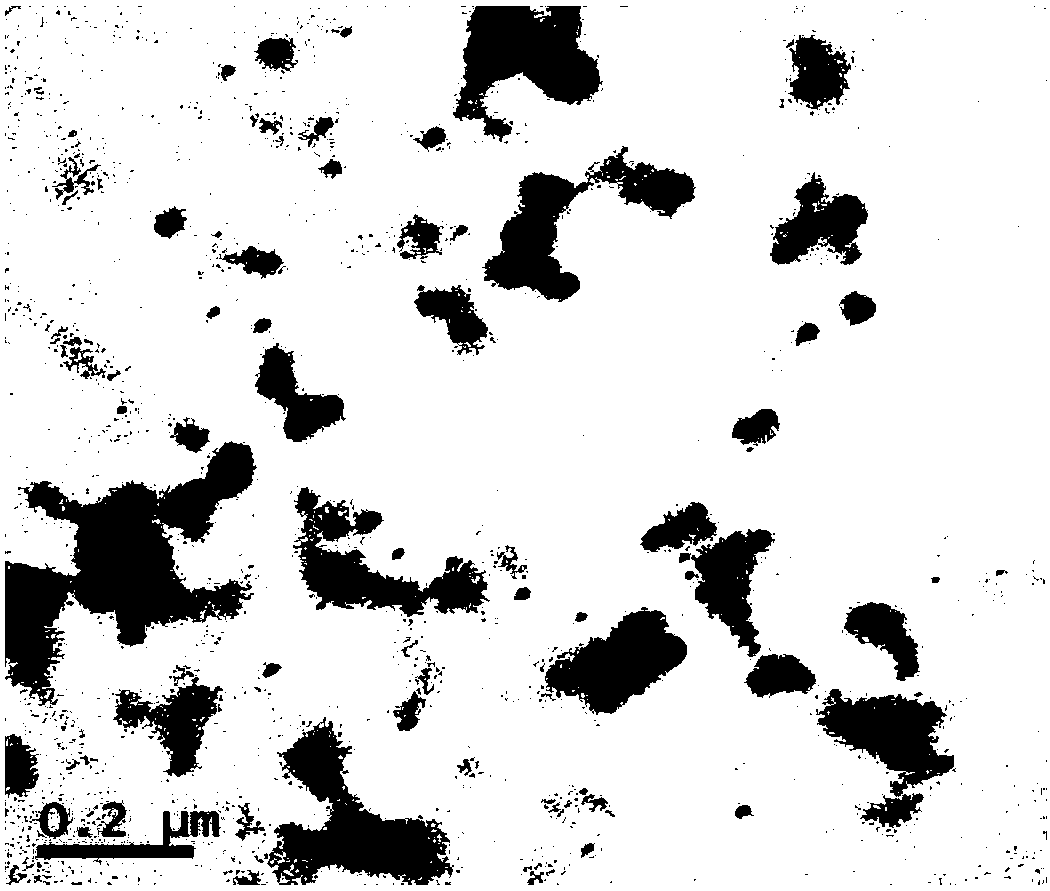

Image

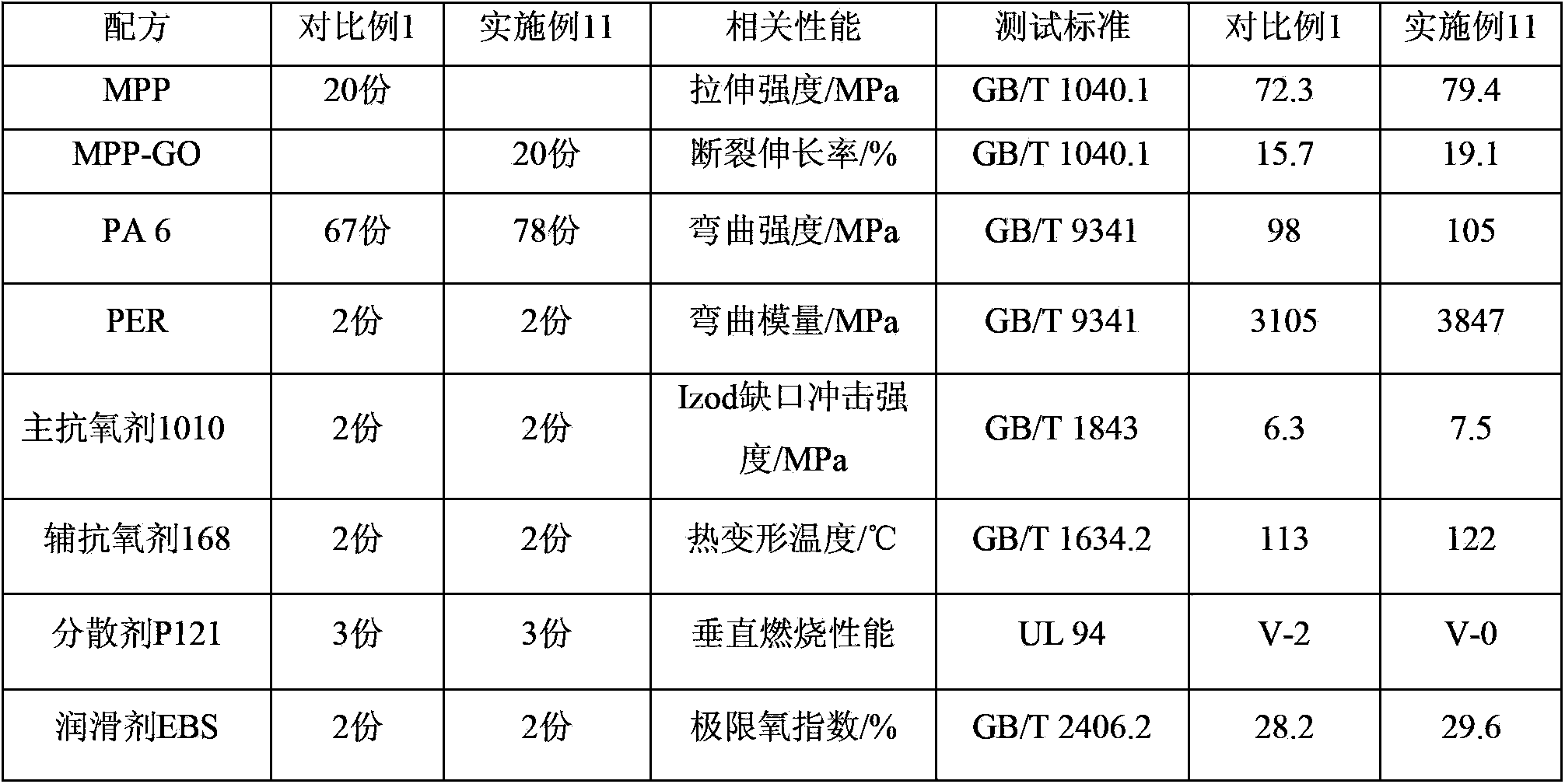

Examples

Embodiment 1

[0033] (1) 50.40g melamine and 26.59g anhydrous sodium pyrophosphate (Na 4 P 2 o 7 ), the molar ratio is 2:1, add it into 500ml distilled water, stir well, the stirring rate is 400r / min, and the stirring time is 30min, so that the system is dispersed evenly;

[0034] (2) Then, add 154 mL of graphene oxide (GO) colloidal solution dispersed by ultrasonic to the system of step (1), the solid content of the graphene oxide colloid is 0.025 g / mL, and the content of graphene oxide GO is 5% of melamine and anhydrous sodium pyrophosphate quality and, and with dripping the dilute nitric acid solution of catalysis, stabilizer, its concentration is 1mol / L, and rate of addition is 2ml / min, and the adjustment reaction system pH value is 4, The temperature was raised to 85°C, the stirring reaction time was 2 hours, and the stirring rate was 360rad / min;

[0035] (3) After the reaction is complete, the reaction product is suction filtered and washed, and the product is dried at 90°C for 48 ...

Embodiment 2

[0037] (1) 50.40g melamine and 26.59g anhydrous sodium pyrophosphate (Na 4 P 2 o 7 ), the molar ratio is 2:1, add it into 350ml distilled water, stir well, the stirring speed is 500r / min, and the stirring time is 15min, so that the system is dispersed evenly;

[0038] (2) Then, add 308ml of graphene oxide (GO) colloidal solution dispersed by ultrasonic to the system of step (1), the solid content of graphene oxide colloid is 0.025g / mL, and the content of graphene oxide GO is 10% of the mass sum of melamine and anhydrous sodium pyrophosphate, and dropwise the dilute nitric acid solution of catalysis and stabilizer, its concentration is 0.5mol / L, and the rate of addition is 2ml / min, and the pH value of the reaction system is adjusted to be 6 , the temperature was raised to 90°C, the stirring reaction time was 4 hours, and the stirring rate was 360rad / min;

[0039] (3) After the reaction is complete, the reaction product is suction filtered and washed, and the product is dried...

Embodiment 3

[0041] (1) 50.40g melamine and 26.59g anhydrous sodium pyrophosphate (Na 4 P 2 o 7 ), the molar ratio is 2:1, add it into 500ml distilled water, stir well, the stirring rate is 400r / min, and the stirring time is 30min, so that the system is evenly dispersed;

[0042](2) Then, add 462ml of graphene oxide (GO) colloidal solution dispersed by ultrasonic to the system of step (1), the solid content of the graphene oxide colloid is 0.05g / mL, and the content of graphene oxide GO is 30% of the mass sum of melamine and anhydrous sodium pyrophosphate, and dripping the dilute nitric acid solution of catalyst and stabilizer, its concentration is 0.5mol / L, and the rate of addition is 2ml / min, and the pH value of the adjustment reaction system is 4 , the temperature was raised to 85°C, the stirring reaction time was 4 hours, and the stirring rate was 360rad / min;

[0043] (3) After the reaction is complete, the reaction product is suction filtered and washed, and the product is dried at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com