Preparation method of one-dimensional ferrous oxalate nanowire

A ferrous oxalate and nanowire technology is applied in the field of preparation of energy storage nanomaterials and achieves the effects of simple preparation process, high purity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Dissolve 4.04 grams of ferric nitrate nonahydrate in a mixed solution of 75 ml of ethylene glycol and 25 ml of water, then add 3.9 grams of oxalic acid, then transfer to a polytetrafluoroethylene reactor, place in an oven and heat to 100 oC , reacted for 15 hours to obtain a precipitate;

[0025] (2) Suction filter the precipitate and wash with deionized water and absolute ethanol;

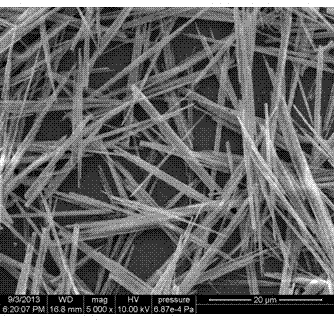

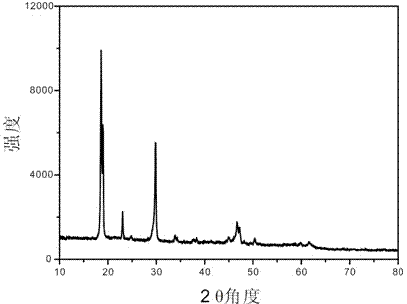

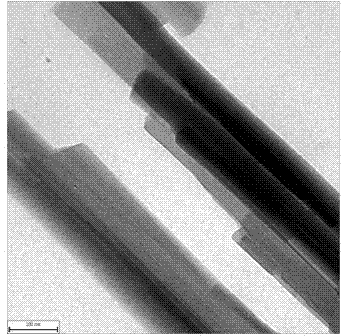

[0026] (3) Put the filter cake in an oven and dry it at 60-80 oC for 12 hours to obtain one-dimensional ferrous oxalate nanowires with a diameter of 150-300 nanometers and a length of 20-100 micrometers.

[0027]

Embodiment 2

[0029] (1) Dissolve 2.70 grams of ferric chloride hexahydrate in a mixed solution of 75 ml of ethylene glycol and 25 ml of water, then add 3.9 grams of oxalic acid, then transfer to a polytetrafluoroethylene reactor, place in an oven and heat to 100 oC, reacted for 15 hours to obtain a precipitate;

[0030] (2) Suction filter the precipitate and wash with deionized water and absolute ethanol;

[0031] (3) Put the filter cake in an oven and dry it at 60-80 oC for 12 hours to obtain one-dimensional ferrous oxalate nanowires with a diameter of 150-300 nanometers and a length of 20-100 micrometers.

Embodiment 3

[0033] (1) Dissolve 4.00 grams of ferric sulfate in a mixed solution of 50 ml of ethylene glycol and 50 ml of water, then add 3.9 grams of oxalic acid, then transfer to a polytetrafluoroethylene reactor, place in an oven and heat to 110 oC, react 24 hours, obtain precipitate;

[0034] (2) The precipitate was centrifuged and washed with deionized water and absolute ethanol;

[0035] (3) Put the product in an oven and dry it at 60-80 oC for 12 hours to obtain one-dimensional ferrous oxalate nanowires with a diameter of 150-300 nanometers and a length of 20-100 micrometers.

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com