Resin vinylidene chloride-acrylic acid ester-acrylic glycidyl ester terpolymer and preparation method thereof

A technology of glyceryl ester terpolymer and glycidyl ester, which is applied in the field of modification of vinylidene chloride, can solve the problems of decreased barrier properties and increased costs, and achieves improved light resistance and barrier properties, low preparation costs, and high production efficiency. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of high barrier resin vinylidene chloride-acrylic acid ester-acrylic glycidyl ester terpolymer, comprising the steps of:

[0040] (1) At normal temperature, add 20kg of deionized water, 0.2g of hydroxypropyl methylcellulose and 0.7g of benzoyl tert-butyl peroxide into the reactor, and stir for 5min at a speed of 80rpm;

[0041] (2) Add 30 kg of vinylidene chloride, 4 kg of methyl acrylate, and 0.5 kg of glycidyl acrylate, set the reaction temperature to 40°C and the stirring speed to 500 rpm, pass condensed water, and react for 5 hours;

[0042] (3) Add 0.03 g of polymethylsiloxane microspheres and 0.3 g of benzoyl tert-butyl peroxide, raise the temperature to 80° C., stir at 500 rpm, and continue stirring for 8 hours to discharge. Centrifuge at 3000rpm for 30min, wash with deionized water and ethanol three times, and finally dry in a vacuum oven at 60°C for 9h to obtain the product.

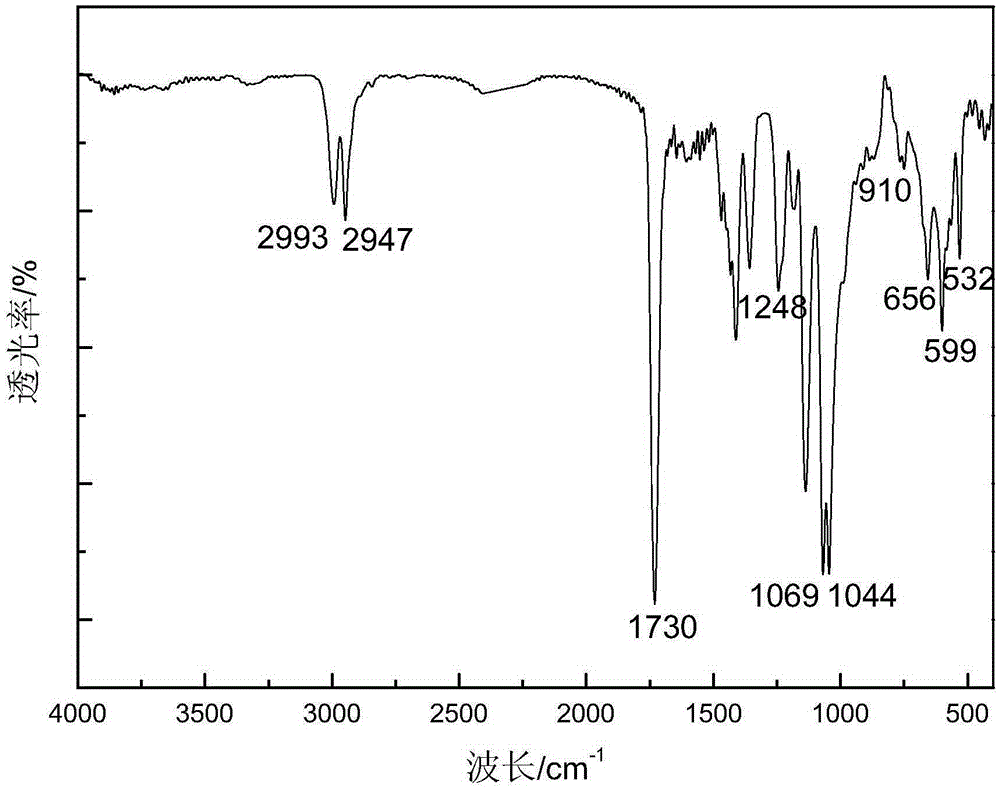

[0043] figure 1 Be the infrared spectrogram of present embodim...

Embodiment 2

[0046] (1) At room temperature, add 20kg of deionized water, 0.5g of gelatin and 1.7g of dimethyl azobisisobutyrate into the reactor, and stir at a speed of 60rpm for 8min;

[0047] (2) Add 35 kg of vinylidene chloride, 3 kg of methyl methacrylate, and 2 kg of glycidyl methacrylate, set the reaction temperature to 35°C and the stirring speed to 800 rpm, pass condensed water, and react for 12 hours;

[0048] (3) Add 0.4 g of polyphenylsiloxane microspheres and 0.3 g of lauroyl peroxide, heat up to 100° C., stir at 700 rpm, and continue stirring for 10 h to discharge. Centrifuge at 4200rpm for 50min, wash twice with deionized water and ethanol, and finally dry in a vacuum oven at 75°C for 12h to obtain the product.

Embodiment 3

[0050] (1) At room temperature, add 20kg of deionized water, 1g of polyvinyl alcohol and 0.6g of azobisisoheptanonitrile into the reactor, and stir for 10min at a speed of 80rpm;

[0051] (2) Add 25 kg of vinylidene chloride, 3 kg of methyl acrylate, and 1.5 kg of glycidyl methacrylate, set the reaction temperature to 70°C and the stirring speed to 650 rpm, pass condensed water, and react for 3 hours;

[0052] (3) Add 0.4 g of polyethylsiloxane microspheres and 0.6 g of azobisisoheptanonitrile, heat up to 90° C., stir at 200 rpm, and continue stirring for 10 h to discharge. Centrifuge at 5500rpm for 20min, wash with deionized water and ethanol three times, and finally dry in a vacuum oven at 70°C for 8h to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com