High temperature-resistant low-infrared emittance composite coating and preparation method thereof

A low-infrared emission, composite coating technology, used in coatings, chemical instruments and methods, metal material coating processes, etc. Emissivity increase, high temperature stability and emissivity improvement, excellent high temperature stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

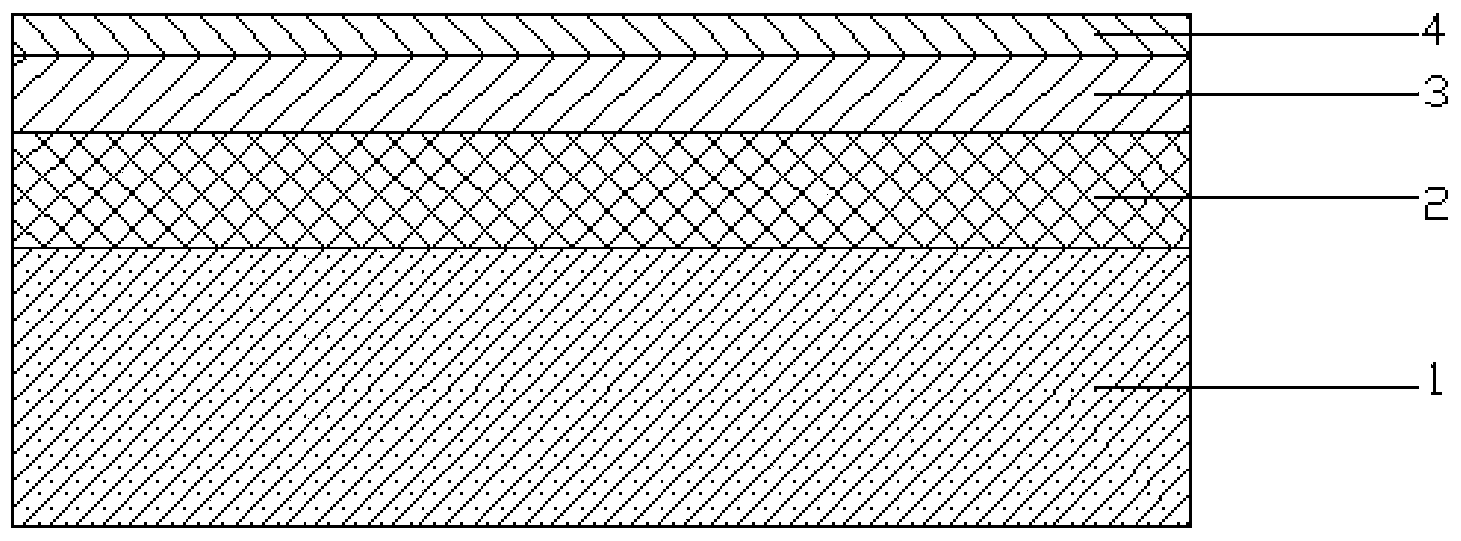

[0043] a kind of like figure 1 and figure 2 The high-temperature-resistant low-infrared emissivity composite coating of the present invention that can be coated on stainless steel or alloys includes a three-layer structure. The composite coating includes a diffusion barrier layer 2 and a low-emissivity functional layer 3 from the inside to the outside. And protective film 4, diffusion barrier layer 2 is ZnO-Al 2 o 3 -SiO 2 Glass-ceramic coating, the low-emissivity functional layer 3 is an Au thin film, and the protective film 4 is an MgO thin film. The surface roughness Ra of the high-temperature-resistant low-infrared emissivity composite coating of the present invention is 1.6 μm, and the coating is particularly suitable for coating on base materials 1 such as 1Cr18Ni9Ti stainless steel plates and K424 alloys for aerospace.

[0044] In the high temperature resistant low infrared emissivity composite coating of this embodiment, ZnO-Al 2 o 3 -SiO 2 ZnO, Al in glass-cer...

Embodiment 2

[0058] a kind of like figure 1 The high-temperature-resistant low-infrared emissivity composite coating of the present invention that can be coated on stainless steel or alloys includes a three-layer structure. The composite coating includes a diffusion barrier layer 2 and a low-emissivity functional layer 3 from the inside to the outside. And protective film 4, diffusion barrier layer 2 is ZnO-Al 2 o 3 -SiO 2 Glass-ceramic coating, the low-emissivity functional layer 3 is an Au thin film, and the protective film 4 is an MgO thin film. The surface roughness Ra of the high-temperature-resistant low-infrared emissivity composite coating of the present invention is 0.8 μm, and the coating is particularly suitable for coating on substrate materials 1 such as 1Cr18Ni9Ti stainless steel plates and K424 alloys for aerospace.

[0059] In the high temperature resistant low infrared emissivity composite coating of this embodiment, ZnO-Al 2 o 3 -SiO 2 ZnO, Al in glass-ceramic coati...

Embodiment 3

[0073] a kind of like figure 1 The high-temperature-resistant low-infrared emissivity composite coating of the present invention that can be coated on stainless steel or alloys includes a three-layer structure. The composite coating includes a diffusion barrier layer 2 and a low-emissivity functional layer 3 from the inside to the outside. And protective film 4, diffusion barrier layer 2 is ZnO-Al 2 o 3 -SiO 2 Glass-ceramic coating, the low-emissivity functional layer 3 is an Au thin film, and the protective film 4 is an MgO thin film. The surface roughness Ra of the high-temperature-resistant low-infrared emissivity composite coating of the present invention is 1.6 μm, and the coating is particularly suitable for coating on base materials 1 such as 1Cr18Ni9Ti stainless steel plates and K424 alloys for aerospace.

[0074] In the high temperature resistant low infrared emissivity composite coating of this embodiment, ZnO-Al 2 o 3 -SiO 2 ZnO, Al in glass-ceramic coating 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com