A kind of high temperature stable x9r type multilayer ceramic capacitor dielectric material and preparation method thereof

A capacitor dielectric and multi-layer ceramic technology, applied in the field of functional ceramic materials, can solve the problems of poor capacitance stability of MLCC, achieve good temperature stability, reduce loss, and simple sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

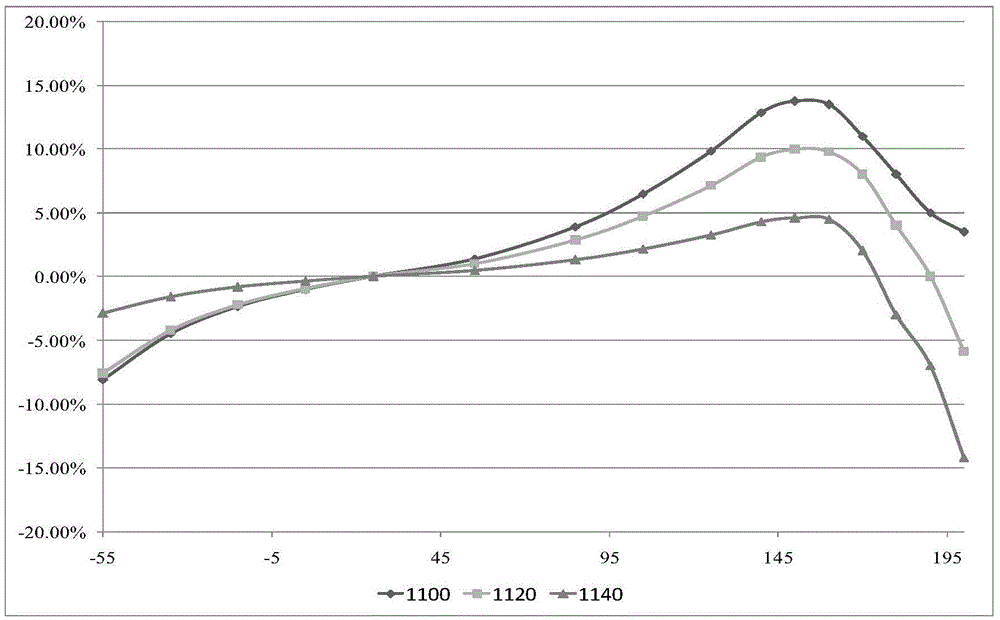

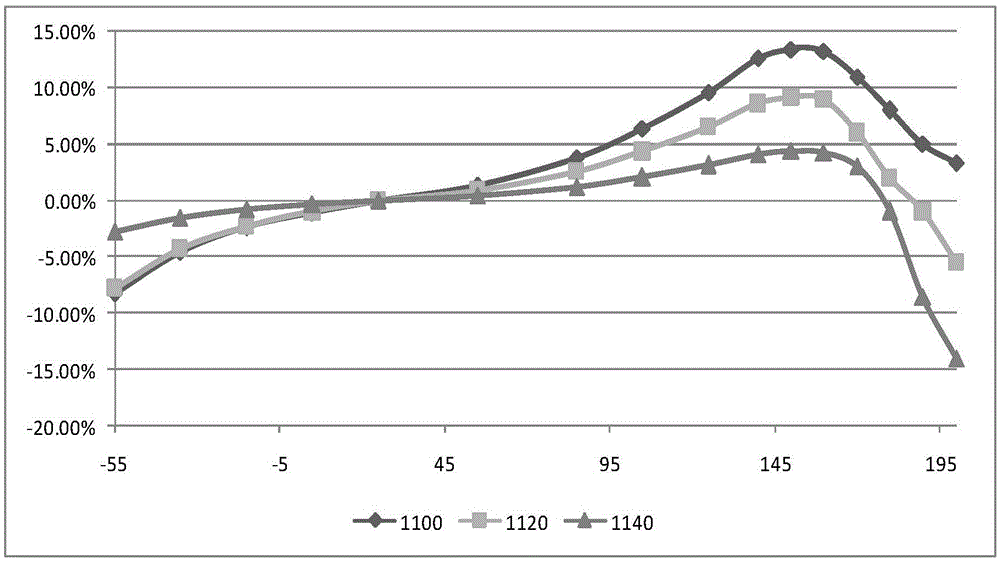

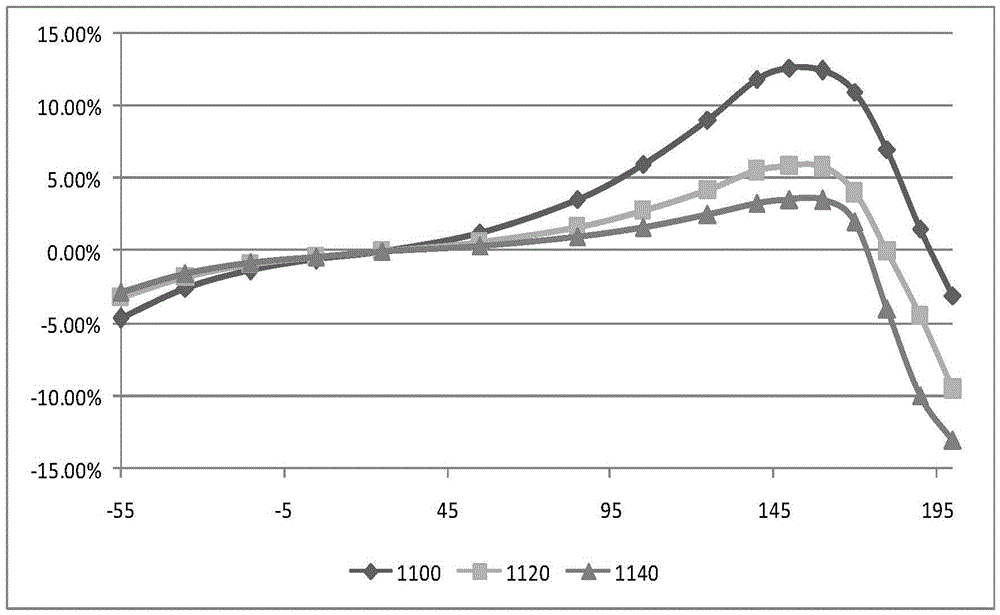

Image

Examples

specific Embodiment 1

[0038] (1) Weigh 52.26gBi respectively 2 o 3 , 11.89gNa 2 CO 3 and 35.85g TiO 2 , mixed ball milling, sieving, and calcining at 800°C for 4 hours to synthesize sodium bismuth titanate;

[0039] (2) Accurately weigh 136.25 g of barium titanate and 13.75 g of bismuth sodium titanate, mix them by ball milling, dry them, crush them through a 40-mesh sieve, and calcinate at 1200° C. for 3 hours to synthesize a co-fusion compound;

[0040] (3) For 53.88g barium titanate and bismuth sodium titanate eutectic compound and 1.12gNb 2 o 5 Weighing, ball milling, drying, crushing through a 40-mesh sieve, and calcining at 1080°C for 3 hours to synthesize the eutectic compound;

[0041] (4) 17.74gCaCO 3 , 10.96gH 3 BO 3 , 21.30gSiO2 2 Weighing, ball milling with alcohol as the medium, drying, crushing through a 40-mesh sieve, and calcining at 800°C for 4 hours to synthesize calcium borosilicate oxide;

[0042] (5) 94.79gBaCO 3 and 55.21 gMnCO 3 Ball milling, drying, crushing, pa...

specific Embodiment 2

[0044] (1) Weigh 52.26gBi respectively 2 o 3 , 11.89gNa 2 CO 3 and 35.85gTiO 2 , mixed ball milling, sieving, and calcining at 900°C for 2 hours to synthesize sodium bismuth titanate;

[0045] (2) Accurately weigh 136.25 g of barium titanate and 13.75 g of bismuth sodium titanate, mix them by ball milling, dry them, crush them through a 40-mesh sieve, and calcinate at 1140° C. for 4 hours to synthesize a co-fusion compound;

[0046] (3) For 53.88g barium titanate and bismuth sodium titanate eutectic compound and 1.12gNb 2 o 5 Weighing, ball milling, drying, crushing through a 40-mesh sieve, and calcining at 1060°C for 4 hours to synthesize the eutectic compound;

[0047] (4) 17.74gCaCO 3 , 10.96gH 3 BO 3 , 21.30gSiO2 2 Weighing, ball milling with alcohol as the medium, drying, crushing through a 40-mesh sieve, and calcining at 800°C for 4 hours to synthesize calcium borosilicate oxide;

[0048] (5) 94.79gBaCO 3 and 55.21 gMnCO 3 Ball milling, drying, crushing thro...

specific Embodiment 3

[0050] (1) Weigh 52.26gBi respectively 2 o 3 , 11.89gNa 2 CO 3 and 35.85gTiO 2 , mixed ball milling, sieving, and calcining at 850°C for 3 hours to synthesize sodium bismuth titanate;

[0051] (2) Accurately weigh 136.25 g of barium titanate and 13.75 g of bismuth sodium titanate, mix them by ball milling, dry them, crush them through a 40-mesh sieve, and calcinate at 1140° C. for 2 hours to synthesize a co-fusion compound;

[0052] (3) For 53.76g barium titanate and bismuth sodium titanate eutectic compound and 1.24gNb 2 o 5 Weighing, ball milling, drying, crushing through a 40-mesh sieve, and calcining at 1120°C for 3 hours to synthesize the eutectic compound;

[0053] (4) 17.74gCaCO 3 , 10.96gH 3 BO 3 , 21.30gSiO2 2 Weighing, ball milling and mixing with alcohol as the medium, drying, crushing through a 40-mesh sieve, and calcining at 900°C for 2 hours to synthesize calcium borosilicate oxide;

[0054] (5) 94.79gBaCO 3 and 55.21 gMnCO 3 Ball milling, drying, cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com