Method for preparing high-purity methyl isobutyl ketone from industrial by-product acetone waste liquid

A technology of methyl isobutyl ketone and industrial by-products, which is applied in the field of preparing high-purity methyl isobutyl ketone from industrial by-product waste liquid acetone, which can solve the disadvantages of separation and purification of MIBK products and recycling of acetone, shortened catalyst life, and the use of Low temperature and other issues to achieve the effect of enhancing product competitiveness, improving product selectivity, and avoiding waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

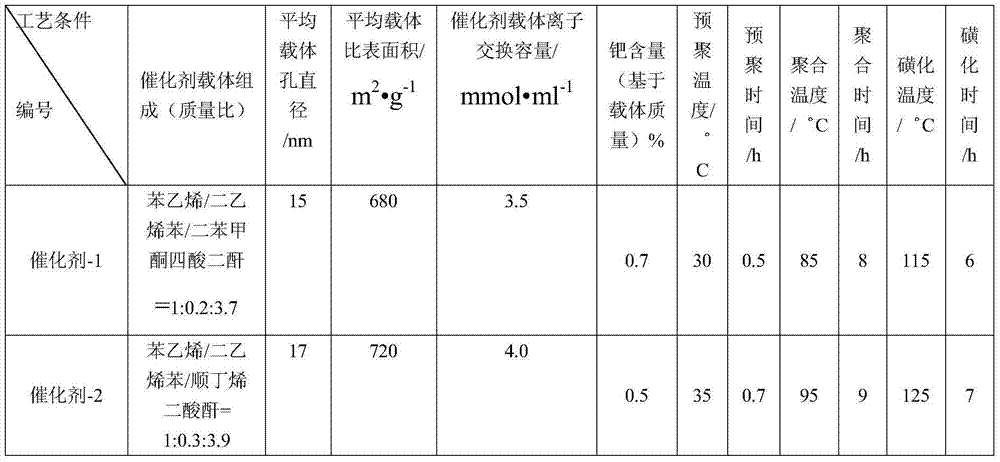

[0045] Mix styrene, divinylbenzene and curing agent evenly according to a certain mass ratio, then add them into the reactor for prepolymerization, and then continue to polymerize at elevated temperature to obtain a resin prepolymer, and then pass the resin prepolymer through the same volume of dichloro Cook with ethane solvent, sulfonate with 98% sulfuric acid, and wash with pure water to obtain the catalyst carrier; add 200ml of catalyst carrier and 200ml of deionized water into the container, and then add 45ml of Pd 2+ The concentration is 0.2-0.5mol / L palladium nitrate-nitric acid-water ternary solution for ion exchange, the H in the solution + The concentration is 0.3mol / L, the exchange time is 30min, and then stirred, the waste liquid is filtered out, washed with deionized water until neutral, and dried at 50°C for 2h to obtain resin-based catalysts with different palladium contents. The specific catalyst labels and process conditions are listed in Table 3.

[0046] Tab...

Embodiment 2

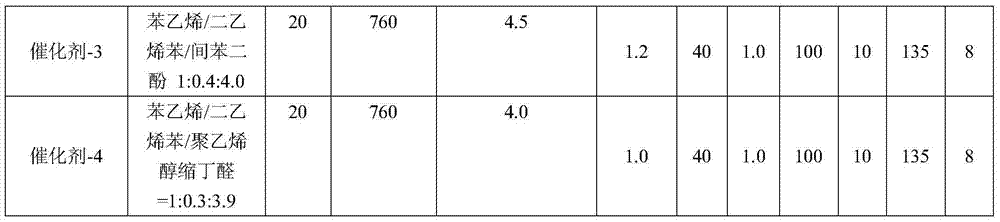

[0050] The Rohm and Haas macroporous ion exchange resin Amb-36 was used to load 0.7wt% palladium, and the catalyst preparation method of Example 1 was used to prepare catalyst-5, which was used for comparison with the catalyst of the present invention. Catalyst-1 and Catalyst-5 were used to synthesize MIBK respectively, and the process parameters are shown in Table 4.

[0051] Table 4 Comparison of MIBK Synthesis by Different Catalysts at Low Temperature and High Temperature

[0052]

[0053]

[0054] Note: Ethers include diisopropyl ether, di-tert-butyl ether, methyl isobutyl ether, methyl tert-butyl ether, etc. Examples 1 and 2 in Table 4 are low-temperature catalytic reaction product compositions, and examples 3 and 4 are high-temperature reaction 4 The composition of the product was checked after one month.

[0055] Drawn from table 4: epoxy isobutane is almost all converted into isobutyraldehyde during low temperature reaction, isobutyraldehyde is a light component...

Embodiment 3

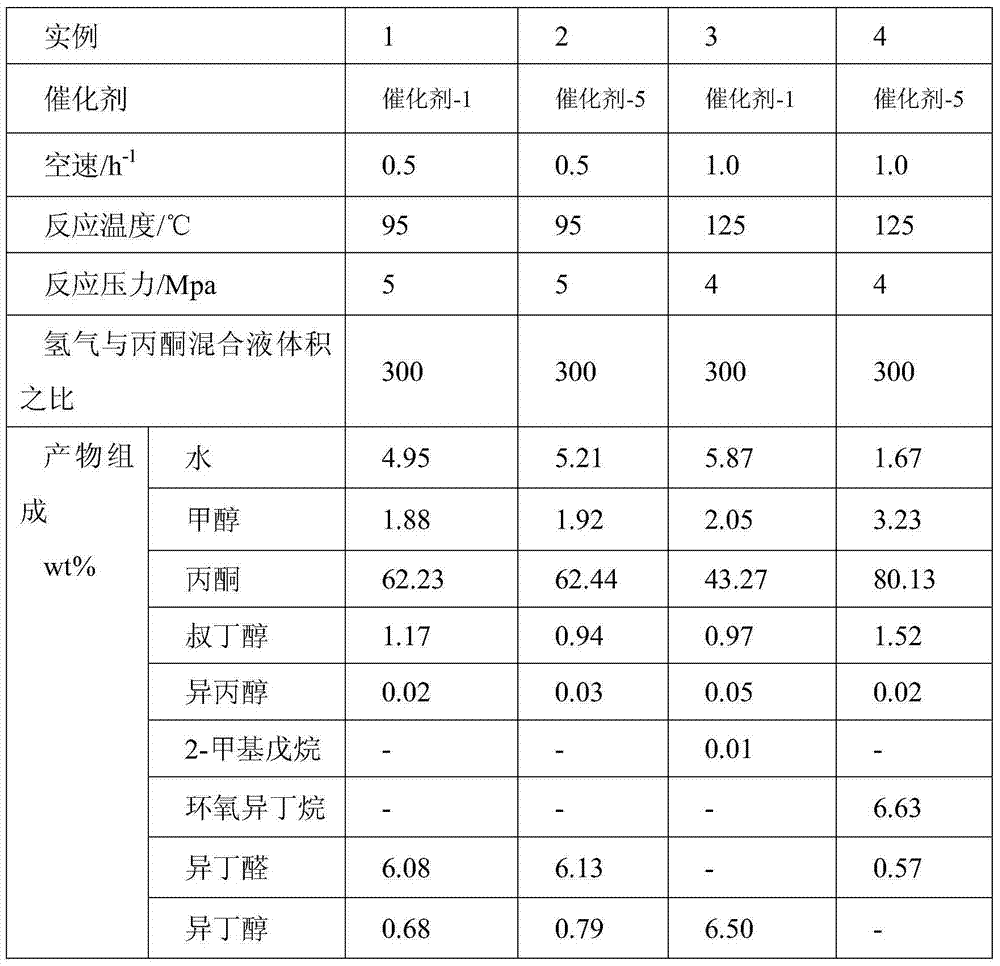

[0057] Pass the industrial by-product waste liquid acetone mixture through the fixed-bed reactor, use catalyst 1-4 as the catalyst and make spherical particles with a diameter of Ф0.3-1.3mm. The inner diameter of the reactor is Ф20mm, and a multi-stage heating insulation system is adopted; the catalyst filling capacity is 100ml; the by-product acetone mixture and hydrogen flow through the catalyst bed in parallel. The liquid samples were collected for analysis, and the specific reaction conditions and results are listed in Table 3.

[0058] Table 5 The reaction conditions and results of synthesizing MIBK

[0059]

[0060] Drawn from Table 5: acetone can catalyze the synthesis of MIBK product in one step, the conversion rate of acetone is moderate, and the selectivity of MIBK is higher; In the raw material, isobutylene oxide is all converted into isobutanol; the slightly increased content of isopropanol shows that a small amount of acetone catalyzes the synthesis It is isop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com