A carbon-coated white carbon black

A technology of carbon-coated white carbon black and white carbon black, which is applied in the direction of fibrous fillers, chemical instruments and methods, and inorganic pigment treatment, can solve the problems of weakening the influence of dispersion, and achieve improved compatibility and good economical performance. Benefits, solve the effect of easy reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

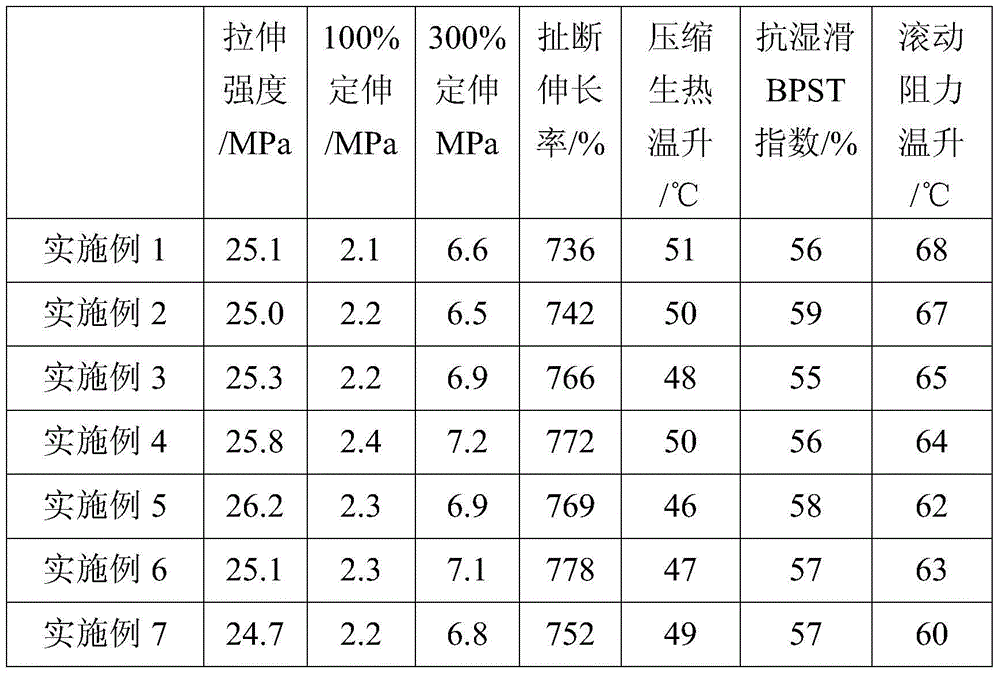

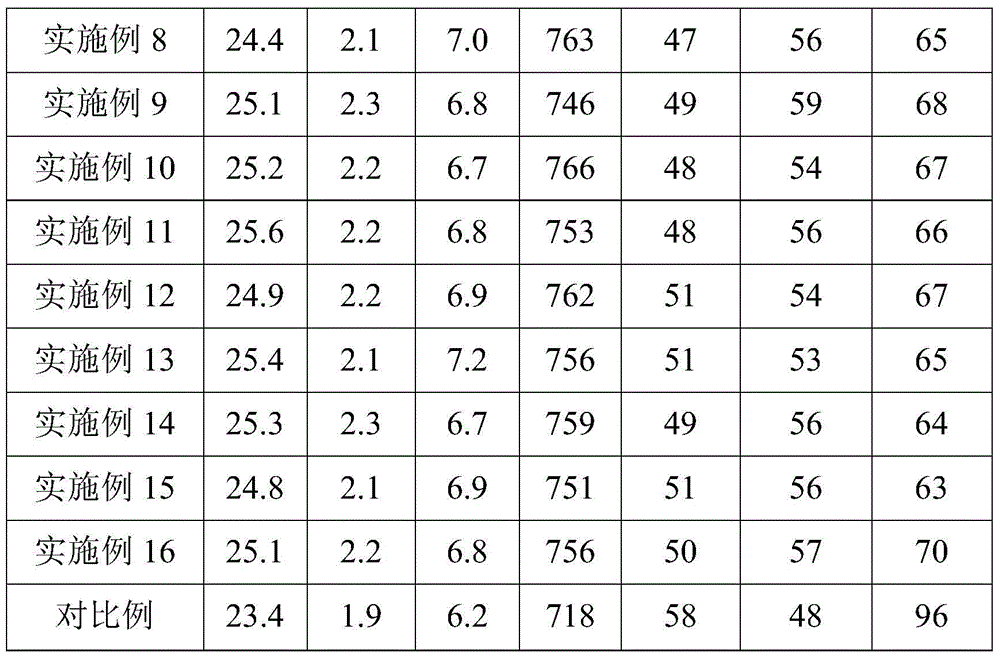

Examples

Embodiment 1

[0055] Add 100g of glutinous rice starch to 900g of water, gelatinize at 80℃ for 1h, take 100g of gelatinized glutinous rice starch solution, mix with 100g of precipitation white carbon black, stir at 50m / min and temperature at 60℃ , Stir uniformly, dry at 105°C to obtain carbon-coated silica, pulverized by a solid pulverizer, and carbonize at 300°C in a tube furnace filled with nitrogen to obtain carbon-coated silica The average particle size is 80nm, the carbon coating layer with 95% carbon content is about 6nm, and the coverage rate of the carbon coating layer is 70%. The mechanical properties are measured after being mixed with rubber according to the specified formula and vulcanized.

Embodiment 2

[0057] Add 100g of tapioca starch to 300g of water, gelatinize at 80℃ for 1h, take 100g of gelatinized tapioca starch solution, mix 100g of fumed white carbon into it, stir at 100m / min and temperature at 70℃ , Stir uniformly, dry at 60°C to obtain carbon-coated silica, pulverized by a solid pulverizer, and carbonize at 400°C in a tube furnace filled with nitrogen to obtain carbon-coated silica The average particle size is 100nm, the carbon coating layer with 96% carbon content is about 10nm, and the carbon coating layer coating rate is 85%. The mechanical properties are measured after being mixed with rubber according to the specified formula and vulcanized.

Embodiment 3

[0059] Add 100g of sucrose to 4900g of water, heat it at 70℃ to fully dissolve it, take 100g of sucrose solution, mix it with 100g of fumed white carbon black, stir evenly at a stirring rate of 120m / min and a temperature of 65℃. Drying at ℃ to obtain carbon-coated white carbon, pulverized by a solid pulverizer, and then carbonized at 500 ℃ in a tube furnace filled with argon to obtain a carbon-coated white carbon with an average particle size of 20nm , The carbon coating layer with 97% carbon content is about 1nm, and the coverage rate of the carbon coating layer is 50%. The mechanical properties are measured after mixing with rubber according to the specified formula and vulcanizing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com