Cement-based composite and mending method of concrete cracks

A composite material, cement-based technology, applied in the field of building materials, can solve problems such as affecting the building structure body, not taking too much consideration of the cracking effect, falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

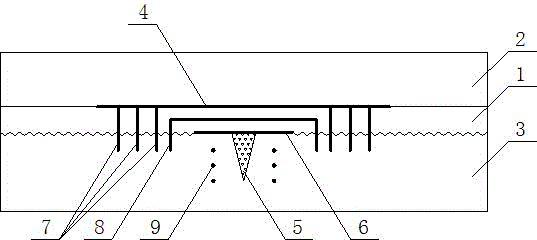

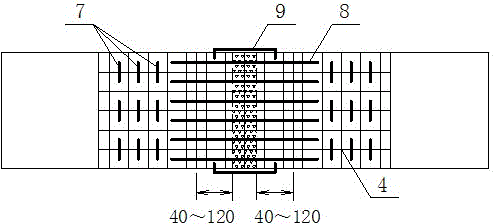

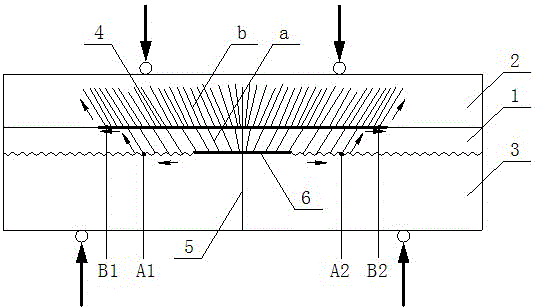

Image

Examples

Embodiment 1

[0065] Example 1: A cement-based composite material. The components of the cement-based composite material include: 45 parts of cement, 23 parts of water, 30 parts of fine aggregate, 48 parts of fly ash, 4.5 parts of silica fume, granulated blast furnace slag 8 parts, mixed with polyvinyl alcohol fibers with a volume of 1.5% of the total volume of the composite material. In this embodiment, a water reducer and a thickener are also included. The number of parts of the water reducer is 0.2 parts, and the number of parts of the thickener is 0.5 parts.

[0066] The particle size of the fine aggregate in this embodiment is less than or equal to 0.5 mm.

[0067] The diameter of the polyvinyl alcohol fiber in this example is 40 μm.

Embodiment 2

[0068] Example 2: A cement-based composite material. The components of the cement-based composite material include: 58 parts of cement, 20 parts of water, 42 parts of fine aggregate, 46 parts of fly ash, 3 parts of silica fume, granulated blast furnace slag 6 parts, also blended with polyethylene fibers at a volume of 2.5% of the total volume of the composite material. In this embodiment, a water reducer and a set retarder are also included, the number of parts of the water reducer is 0.5 part, and the part of the set retarder is 0.2 part.

[0069] The particle size of the fine aggregate in this embodiment is less than or equal to 0.5mm.

[0070] The diameter of the polyethylene fiber in this example is 50 µm.

Embodiment 3

[0071] Example 3: A cement-based composite material. The components of the cement-based composite material include: 69 parts of cement, 23 parts of water, 30 parts of fine aggregate, 48 parts of fly ash, 2 parts of silica fume, granulated blast furnace slag 5 parts, also mixed with carbon fiber whose volume is 2.0% of the total volume of the composite material. In this embodiment, a water reducing agent and a setting retarder are also included, the number of parts of the water reducing agent is 0.2 parts, and the number of parts of the setting retarder is 0.5 parts.

[0072] The particle size of the fine aggregate in this embodiment is less than or equal to 0.5 mm.

[0073] The diameter of the carbon fiber in this example is 60 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com