Method for producing DHA through Crypthecodinium cohnii fermentation

A dinoflagellate and fermenter technology, which is applied in the field of mixed oils and fats, can solve the problems of low genome predictability, unsuitability for large-scale production, low long-term genetic stability, etc., so as to improve market competitiveness and reduce production. Cost, high oil yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 130

[0021] Embodiment 1.30L fermentor dinoflagellates ferment and produce DHA

[0022] The fresh dinoflagellate slant strains were inserted into a 2L shaker flask with 350mL medium and cultured for 48h at a shaker speed of 180rpm to prepare a DHA seed solution with a cell density of 8g / L.

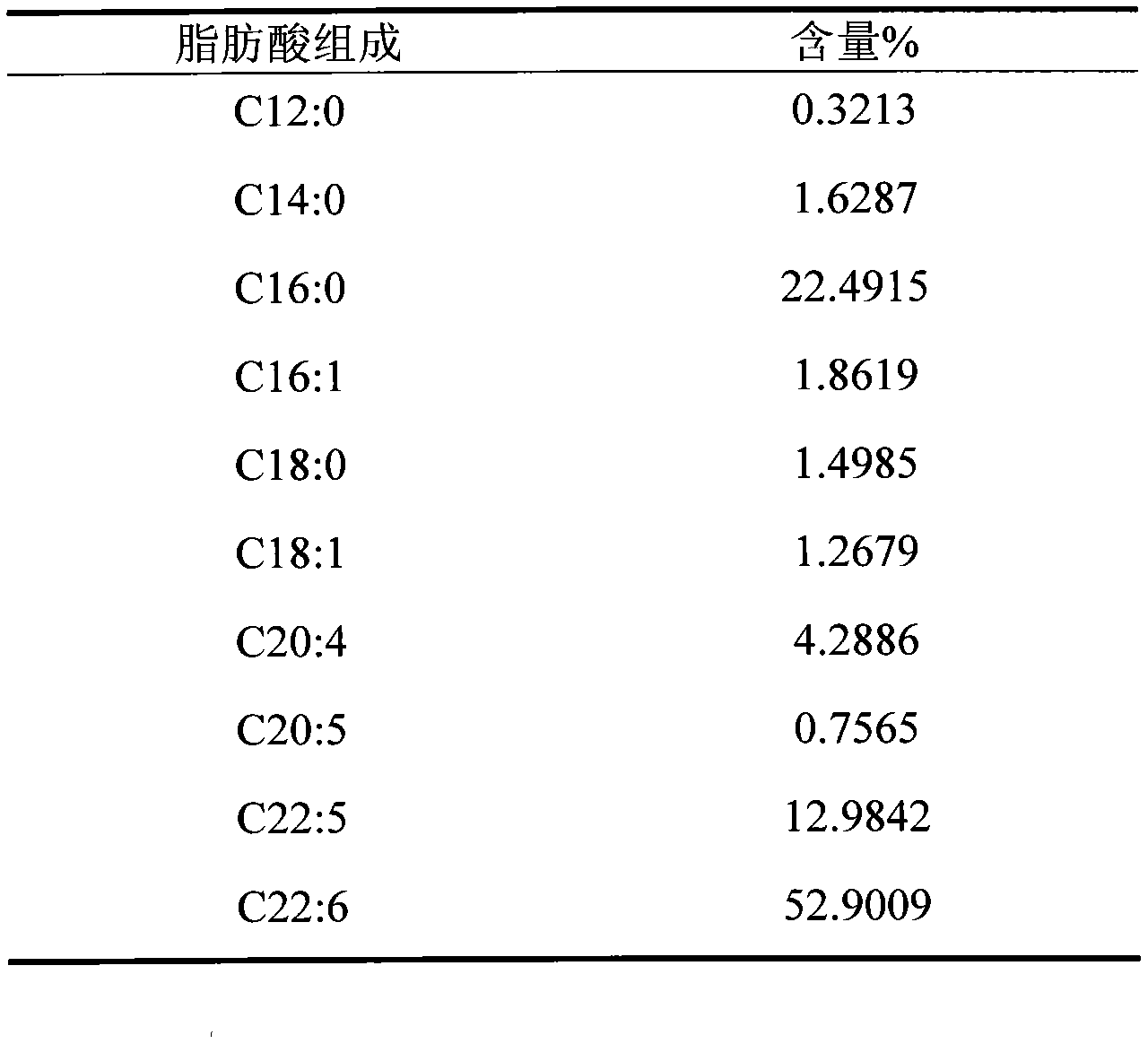

[0023] In a 30L fermenter, insert the DHA seed liquid into the sterilized medium according to the inoculum amount of 3%, the volume after connection is 20L, the tank pressure is 0.02MPa, the initial stirring speed is 120rpm, the ventilation rate is 1vvm, and the dissolved oxygen speed is passed. The coupling controls the DO at about 50%. The whole fermentation process is fed with 40% ammonia water to control the pH at about 6.8. During the process, the carbon source is fed to control the glucose concentration at 1-5g / L. After 68 hours of cultivation, the fermentation is stopped and the tank is placed. The dry cell weight in the fermentation broth is determined to be 84g / L, the oil content is 50...

Embodiment 2100

[0026] Embodiment 2.100L fermentation tank dinoflagellates ferment and produce DHA

[0027] The fresh dinoflagellate slant strains were inserted into a 2L shaker flask with 350mL medium and cultured for 48h at a shaker speed of 180rpm to prepare a DHA seed solution with a cell density of 7g / L.

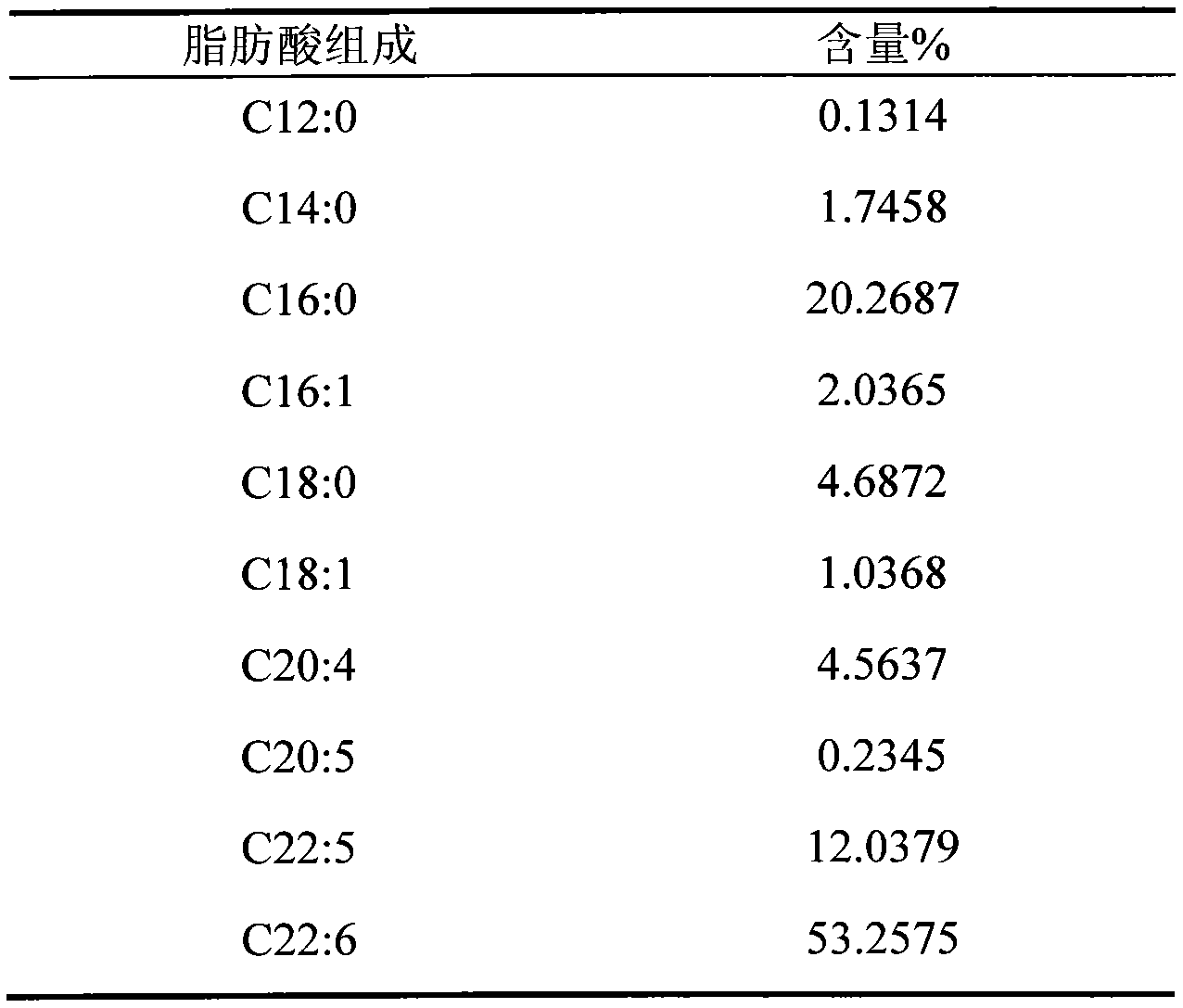

[0028] In a 100L fermenter, insert the DHA seed liquid into the sterilized medium according to the inoculation amount of 3%, the volume after connection is 50L, the tank pressure is 0.02MPa, the initial stirring speed is 120rpm, the ventilation rate is 1vvm, and the dissolved oxygen speed is passed. The coupling controls the DO at about 50%. The whole fermentation process is fed with 40% ammonia water to control the pH at about 6.8. During the process, the carbon source is fed to control the glucose concentration at 1-5g / L. After 72 hours of fermentation, the fermentation is stopped and the tank is placed. The dry cell weight in the fermentation broth was determined to be 91g / L, the oi...

Embodiment 3

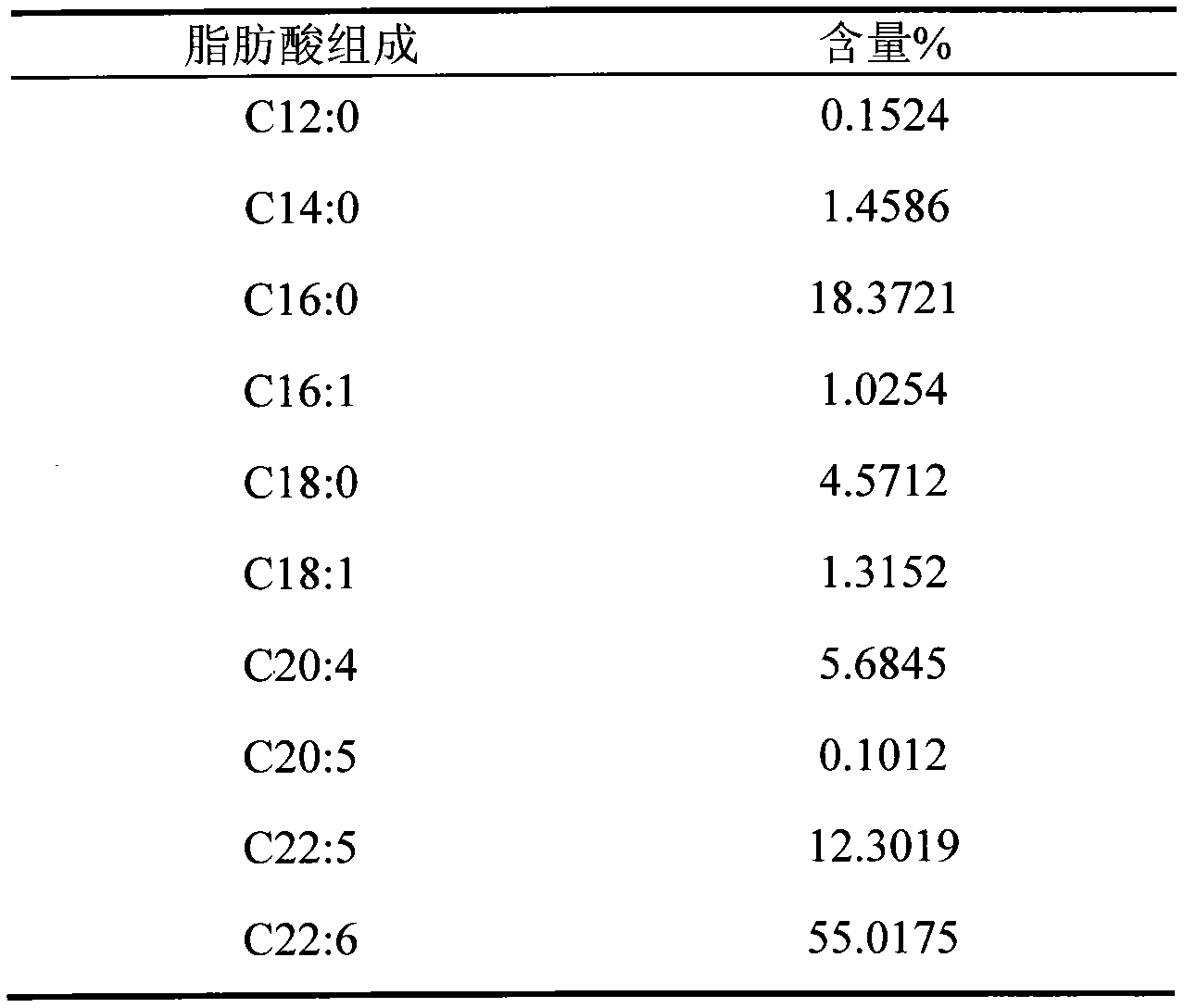

[0031] Example 3.100m 3 Fermentation of dinoflagellation algae to produce DHA in a fermenter

[0032] Carry out industrial expansion culture to dinoflagellates, the process is as follows:

[0033] Put the fresh dinoflagellate slant strains into a 2L shake flask with 350mL of medium, culture on a shaker at 28°C for 48h, and the shaker rotates at 180rpm to prepare DHA seed solution with a cell density of 9g / L.

[0034] In the first-level seed tank, the DHA seed solution in the shake flask was inserted into the sterilized first-level seed tank culture medium according to the inoculum amount of 0.4%, the ventilation rate was 1vvm, the pressure was 0.02MPa, the stirring speed was 20Hz, and cultivated for 30h , The measured dry cell weight in the fermentation broth was 5g / L.

[0035] In the secondary seed tank, insert the primary seeds into the sterilized medium of the secondary seed tank according to the inoculation amount of 3%, the pressure is 0.02MPa, the stirring speed is 25H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com