Adsorption-catalytic oxidation degrading method for phenol in waste water

A technology for phenol and wastewater, applied in the field of water treatment, can solve problems such as desorption and regeneration, and achieve the effects of no secondary pollution, good effect, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] 1. Activated carbon fiber loaded with Fe3O4 (Fe 3 O 4 / ACF) Preparation:

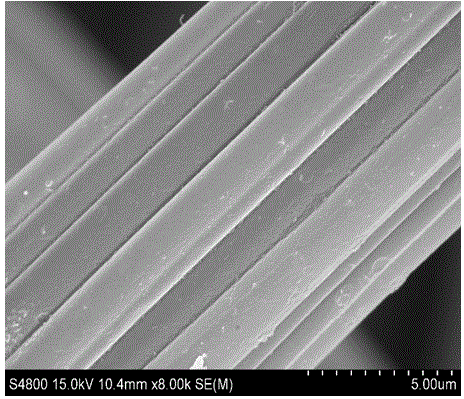

[0021] 1. Activated carbon fiber (ACF): using viscose-based activated carbon fiber felt sold on the market (specific surface area greater than 1100m 2 / g). See the scanning electron microscope picture figure 1 .

[0022] 2. Fe 3 O 4 Preparation:

[0023] Take 6.0 g FeCl respectively 3 ·6H 2 O, 3.0 g polyvinylpyrrolidone (PVP) and 6.0 g anhydrous NaAc, add 120 mL ethylene glycol, and stir for 2.0 h at room temperature to ensure that all solid materials are dissolved in ethylene glycol. The above mixture was transferred to a stainless steel reactor lined with polytetrafluoroethylene, and the above mixture was reacted at 200°C for 6.0 hours. After the reaction, it was cooled to room temperature naturally, washed with distilled water several times, and dried under vacuum at 60°C for 24 h.

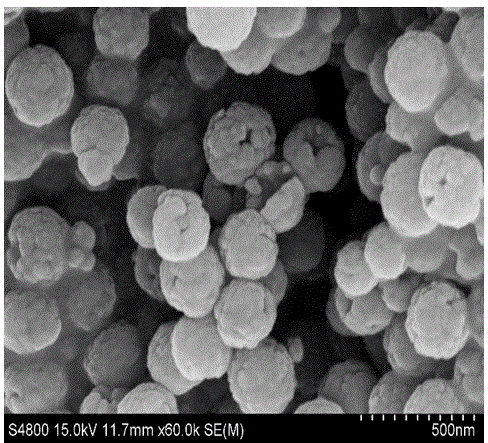

[0024] Fe prepared 3 O 4 See the SEM picture figure 2 .

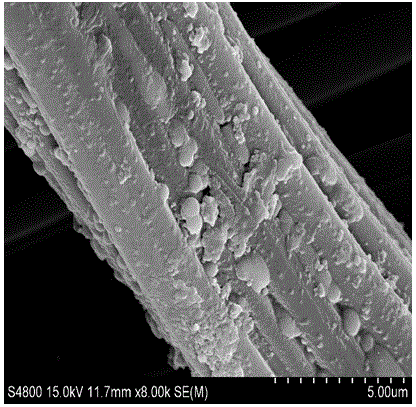

[0025] 3. Fe 3 O 4 / ACF preparation:

[0026] Other conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com