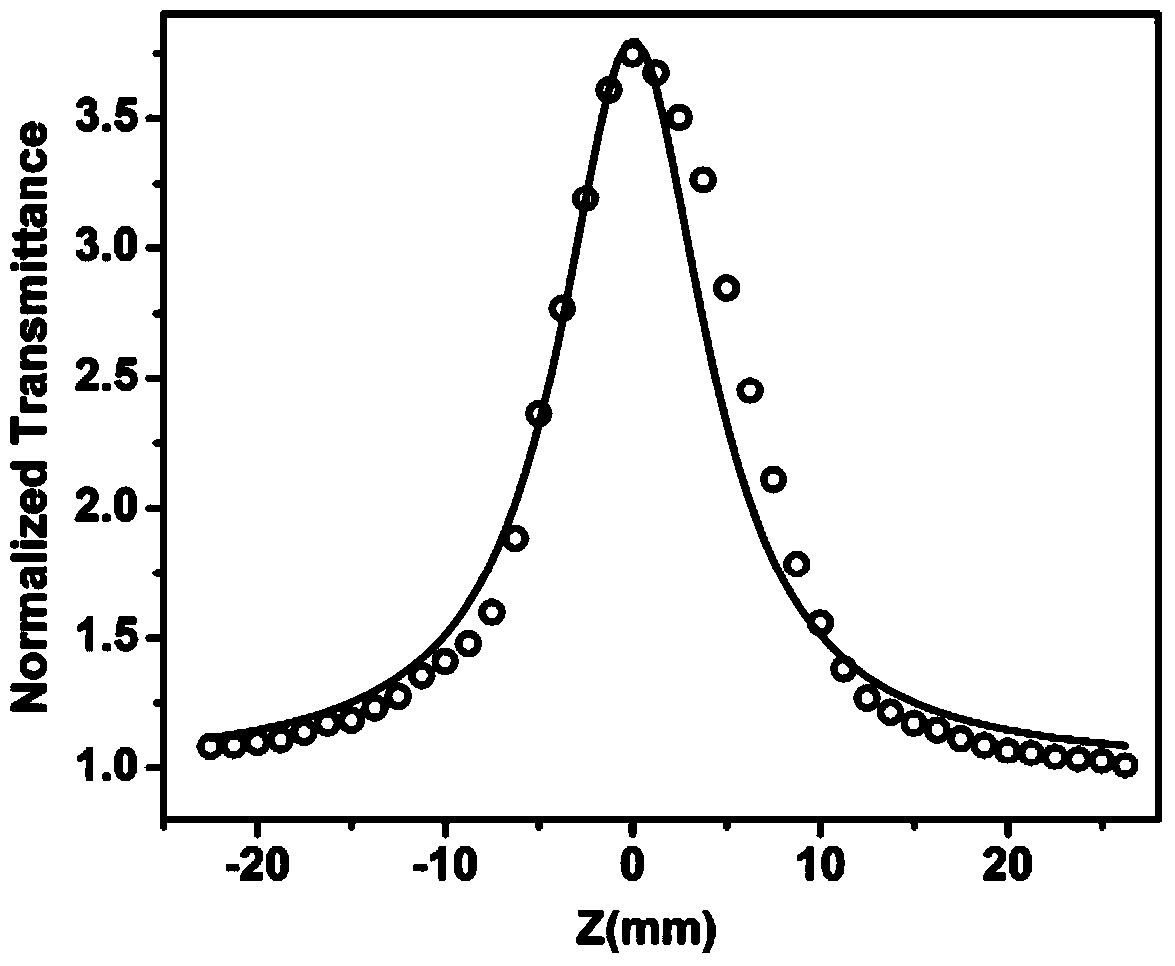

Phthalocyanine-polyoxometallate third-order nonlinear optical self-assembled film and preparation method thereof

A polyoxometalate and third-order nonlinear technology, which is applied in chemical instruments and methods, synthetic resin layered products, and layered products, can solve the problems of difficult control of film thickness, complicated equipment, and high cost, and achieve cost-effectiveness. The effect of rich film material, compact packing and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

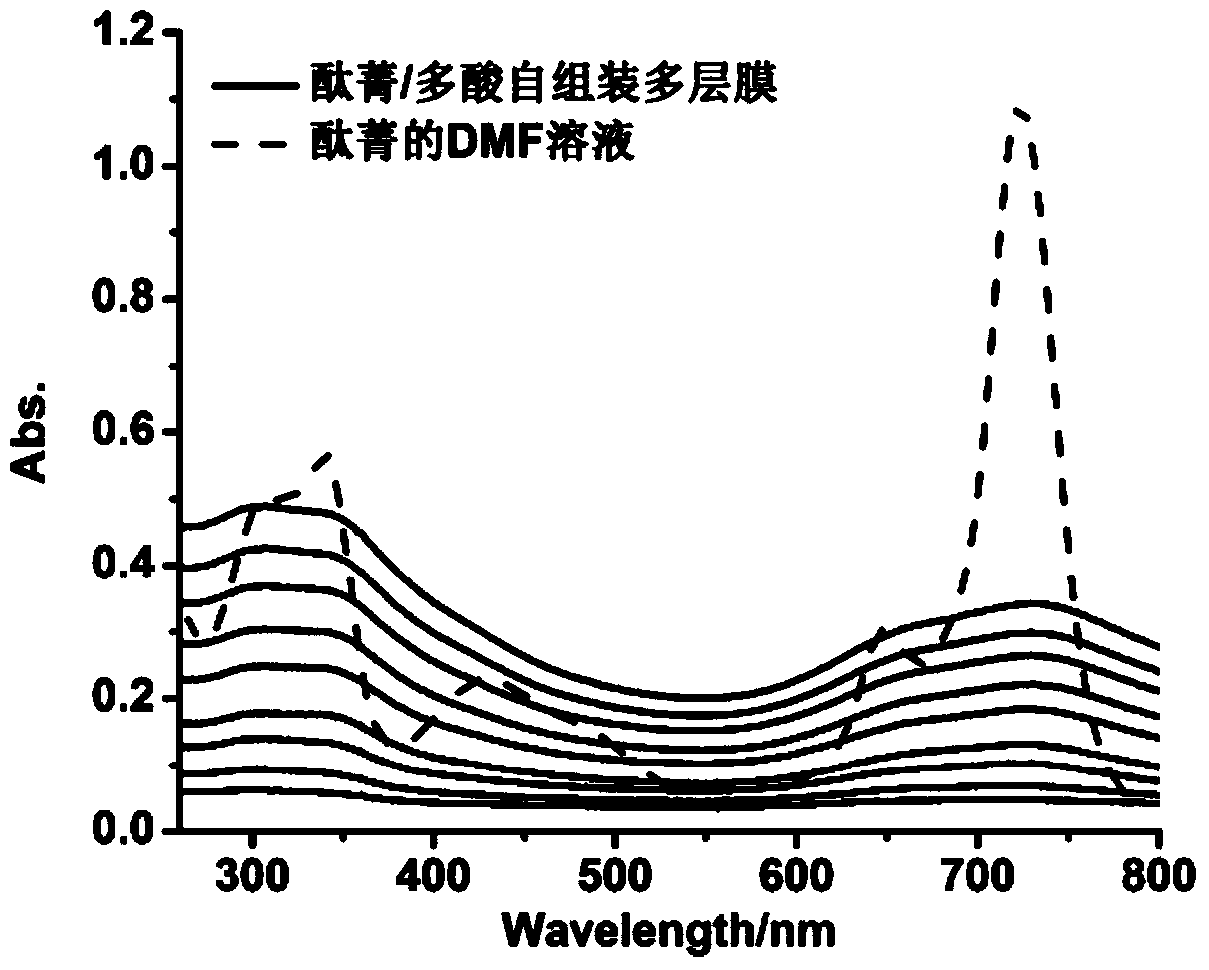

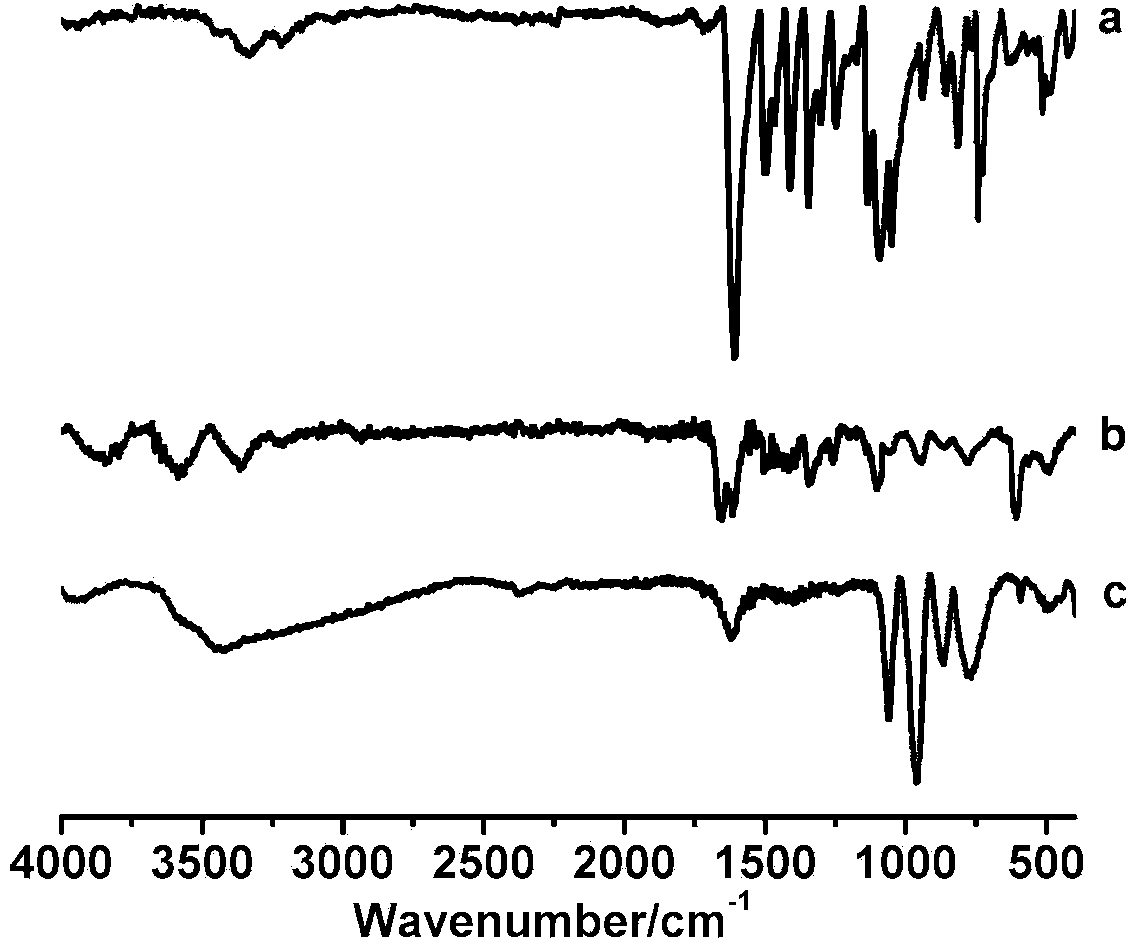

Embodiment 1

[0025] (1) prepare the aqueous solution of polyallylamine hydrochloride and NaCl, the concentration of polyallylamine hydrochloride is 1.0 * 10 -2 mol / L, the NaCl concentration is 1M, and the pH is adjusted to 2.5 with hydrochloric acid; the prepared concentration is 1.0×10 -2 mol / L sodium polystyrene sulfonate aqueous solution; the preparation concentration is 1.0×10 -3 mol / L DMF (N,N-dimethylformamide) solution of 2,9,16,23-tetraaminocopper phthalocyanine; the preparation concentration is 1.0×10 -3 mol / L of H 5 PMo 10 V 2 o 40 Aqueous solution, adjust pH=2.5 with hydrochloric acid;

[0026] (2) Put the processed quartz sheet into the aqueous solution of polyallylamine hydrochloride and NaCl, soak for 20min, take it out, wash it with deionized water and dry it with nitrogen;

[0027] (3) Then soak the quartz sheet in an aqueous solution of sodium polystyrene sulfonate for 20 minutes, take it out, wash it with deionized water and blow it dry with nitrogen; then put it in...

Embodiment 2

[0036] (1) prepare the aqueous solution of polyallylamine hydrochloride and NaCl, the concentration of polyallylamine hydrochloride is 1.0 * 10 -2 mol / L, the concentration of NaCl is 1M, adjust the pH=1 with hydrochloric acid; the prepared concentration is 1.0×10 -2 mol / L sodium polystyrene sulfonate aqueous solution; the preparation concentration is 1.0×10 -3 mol / L DMF (N,N-dimethylformamide) solution of 2,9,16,23-tetraaminocopper phthalocyanine; the preparation concentration is 1.0×10 -3 mol / L of H 3 PMo 12 o 40 Aqueous solution, adjust pH=1 with hydrochloric acid;

[0037] (2) Put the treated monocrystalline silicon chip into the aqueous solution of polyallylamine hydrochloride and NaCl, soak for 20min, take it out, wash it with deionized water and dry it with nitrogen;

[0038] (3) Soak the monocrystalline silicon wafer in an aqueous solution of sodium polystyrene sulfonate for 20 minutes, take it out, wash it with deionized water and dry it with nitrogen; then soak i...

Embodiment 3

[0045] (1) prepare the aqueous solution of polyallylamine hydrochloride and NaCl, the concentration of polyallylamine hydrochloride is 1.0 * 10 -3 mol / L, the concentration of NaCl is 1M, adjust the pH=5 with hydrochloric acid; the prepared concentration is 1.0×10 -3 mol / L sodium polystyrene sulfonate aqueous solution; the preparation concentration is 1.0×10 -4 mol / L DMF solution of 2,9,16,23-tetraaminocopper phthalocyanine; the preparation concentration is 1.0×10 -2 mol / L of H 3 PW 12 o 40 Aqueous solution, adjust pH=5 with hydrochloric acid;

[0046] (2) Put the treated non-woven fabric into the aqueous solution of polyallylamine hydrochloride and NaCl, soak for 10min, take it out, wash it with deionized water and dry it with nitrogen;

[0047] (3) Then soak the substrate in an aqueous solution of sodium polystyrene sulfonate for 30 minutes, take it out, wash it with deionized water and blow it dry with nitrogen; then soak it in an aqueous solution of polyallylamine hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com