Low-temperature plasma membrane-type artificial lung modification method

A low-temperature plasma and artificial lung technology, applied in suction devices, dialysis systems, etc., can solve problems such as insufficient biocompatibility, and achieve remarkable effects and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

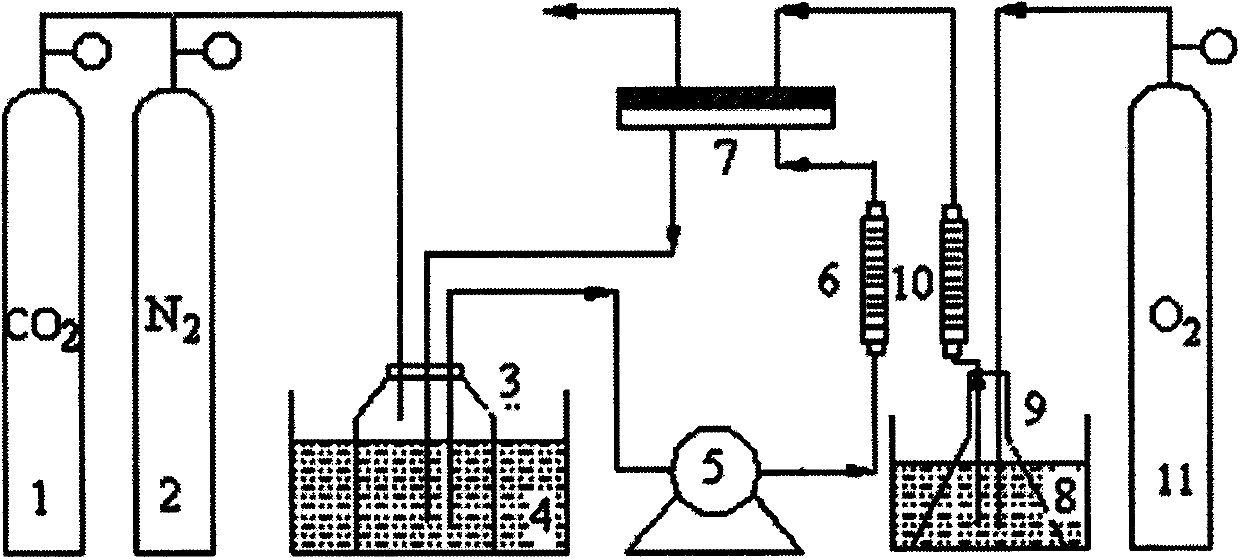

Method used

Image

Examples

Embodiment 1

[0021] Soak the poly-4-methyl-1-pentene membrane used in membrane-type artificial lung in deionized water for 24 hours, dry it in a vacuum drying oven, put the dried membrane into the chamber of the plasma processor, and the system Vacuumize to 20Pa, pass in argon gas, stabilize the working gas pressure at 20Pa, start the radio frequency power supply, adjust the discharge power to 300W, the processing time is 5min, and the gas flow rate is 60ml / min. After the treatment, stop the discharge and gas supply, do not take out the sample, pass 2-methacryloyloxyethylphosphorylcholine steam into the cavity to initiate gas phase grafting, and stabilize the steam pressure at 20Pa, start the radio frequency power supply, adjust The discharge power treatment is 300W, and the treatment time is 5min.

Embodiment 2

[0023] Soak the poly-4-methyl-1-pentene membrane used in membrane-type artificial lung in deionized water for 24 hours, dry it in a vacuum drying oven, put the dried membrane into the chamber of the plasma processor, and the system Vacuumize to 20Pa, inject oxygen, stabilize the working gas pressure at 20Pa, start the radio frequency power supply, adjust the discharge power to 30W, the processing time is 1min, and the gas flow rate is 120ml / min. After the treatment, stop the discharge and gas supply, do not take out the sample, pass 2-methacryloyloxyethylphosphorylcholine steam into the cavity to initiate gas phase grafting, and stabilize the steam pressure at 20Pa, start the radio frequency power supply, adjust The discharge power is 30W, and the treatment time is 1min.

Embodiment 3

[0025] Soak the poly-4-methyl-1-pentene membrane used in membrane-type artificial lung in deionized water for 24 hours, dry it in a vacuum drying oven, put the dried membrane into the chamber of the plasma processor, and the system Vacuumize to 20Pa, inject carbon dioxide, stabilize the working gas pressure at 20Pa, start the RF power supply, adjust the discharge power to 200W, the processing time is 2min, and the gas flow rate is 30ml / min. After the treatment, stop the discharge and gas supply, do not take out the sample, pass 2-methacryloyloxyethylphosphorylcholine steam into the cavity to initiate gas phase grafting, and stabilize the steam pressure at 20Pa, start the radio frequency power supply, adjust The discharge power treatment is 200W, and the treatment time is 2min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com