Vanadium-containing MCM-41 heteroatom molecular sieve catalyst as well as preparation method and application thereof

A technology of MCM-41 and heteroatom molecular sieves, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as not being able to meet market demand, and achieve good economic benefits, high activity, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 0.4g of NaOH in 200mL of deionized water at 60°C, add 2.5g of cetyltrimethylammonium bromide (CTAB), stir for 1 hour, then add 0.6g of ammonium metavanadate (NH 4 VO 3 ), after it dissolved, 12.4 mL of tetraethyl orthosilicate (TEOS) was slowly added dropwise, then vigorously stirred for 6 hours, and then aged at room temperature for 24 hours. The resulting liquid was poured into a polytetrafluoroethylene-lined stainless steel crystallization kettle, crystallized in a blast drying oven at 120°C for 48 hours, and then cooled at room temperature. Then the obtained liquid was divided into 10mL centrifuge tubes, washed by centrifugation at 3600r / min, and then dried in a blast drying oven at 60°C. The dried catalyst powder was placed in a muffle furnace and calcined at 550° C. for 4 hours, and then sieved into catalysts of required mesh.

Embodiment 2

[0025] Get 0.2g of the catalyst in Example 1, carry out the propane oxidative dehydrogenation reaction in a catalytic dehydrogenation test device, the reaction temperature is 600°C, the reaction pressure is normal pressure, and the propane space velocity is 6h -1 , the mass flow ratio of reaction gas propane and carbon dioxide is 1:1. The catalyst is used in the reaction of carbon dioxide oxidation and dehydrogenation of propane, the conversion rate of propane is 33.2%, the selectivity of propylene is 89%, and the yield of carbon monoxide is 8.3%.

Embodiment 3

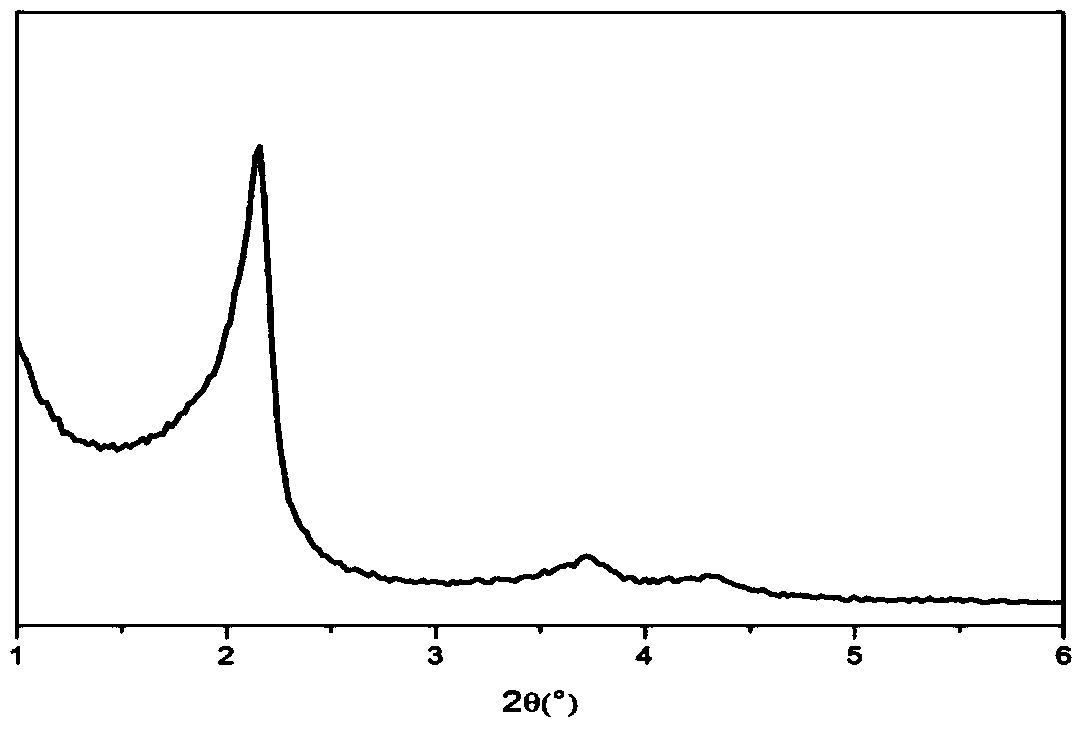

[0027] Dissolve 0.4g of NaOH in 150mL of deionized water at 60°C, add 2.5g of cetyltrimethylammonium bromide (CTAB), stir for 1 hour, then add 0.6g of ammonium metavanadate (NH 4 VO 3 ), after it dissolved, 12.4 mL of tetraethyl orthosilicate (TEOS) was slowly added dropwise, then vigorously stirred for 6 hours, and then aged at room temperature for 24 hours. The resulting liquid was poured into a polytetrafluoroethylene-lined stainless steel crystallization kettle, crystallized in a blast oven at 120°C for 72 hours, and then cooled at room temperature. Then the obtained liquid was divided into 10mL centrifuge tubes, centrifuged and washed at a speed of 3600r / min, and then dried in a blast drying oven at 100°C. The dried catalyst powder was placed in a muffle furnace and calcined at 550° C. for 4 hours, and then sieved into catalysts of required mesh. figure 1 The XRD pattern in the middle shows that the synthesized sample has the characteristic diffraction peaks of (100), (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com