Preparation method of aluminum alloy surface composite coating layer

A technology of aluminum alloy surface and composite coating, which is applied in the field of laser processing, can solve the problems of nanostructure NiCrAl/TiC composite coating, low efficiency, complicated process, etc. The effect of high light absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

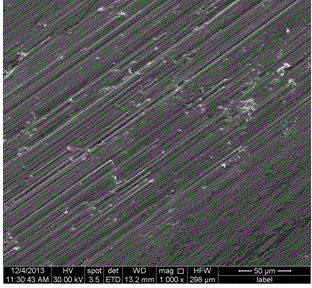

[0033] (1) Cut the aluminum alloy plate into a laser cladding sample, and perform shot blasting on the cladding surface of the aluminum alloy plate sample;

[0034] (2) Use acetone and alcohol to remove oxides, impurities and oil stains on the surface of cladding samples;

[0035] (3) Dry the NiCrAl powder at 70°C for 8 hours to obtain the pretreated NiCrAl powder, wherein the NiCrAl powder is mixed with 60 nm Ni, Cr and Al powder, and the mass percentage of Cr in the NiCrAl powder is 16%, The mass percentage of Al is 6%, and the mass percentage of Ni powder is 78%;

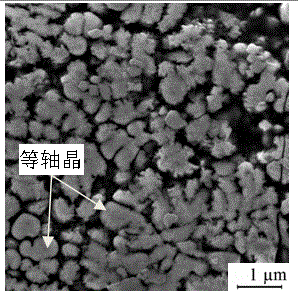

[0036] (4) Using cross-flow multimode CO 2 The laser cladding NiCrAl powder on the aluminum alloy plate sample to obtain a composite coating, in which the laser power is 3.8 kW, the scanning speed is 420 mm / min, the NiCrAl powder feeding rate is 0.5 g / s, the protective gas flow rate is 8 L / h, and the defocus The measurement is 40 mm, the spot diameter is 5 mm, the thickness of the composite coating is 1.0 mm, a...

Embodiment 2

[0041] (1) Cut the aluminum alloy plate into a laser cladding sample, and perform shot blasting on the cladding surface of the aluminum alloy plate sample;

[0042] (2) Use acetone and alcohol to remove oxides, impurities and oil stains on the surface of cladding samples;

[0043] (3) Dry NiCrAl powder and TiC powder at 85°C for 7 hours to obtain pretreated NiCrAl powder and TiC powder, wherein the powder particle size of NiCrAl powder and TiC are both 80nm, and NiCrAl powder is made of 80nm Ni, Cr, Al The powder is mixed, and the mass percent of Cr is 17% in NiCrAl powder, and the mass percent of Al is 7%, and the mass percent of Ni powder is 76%;

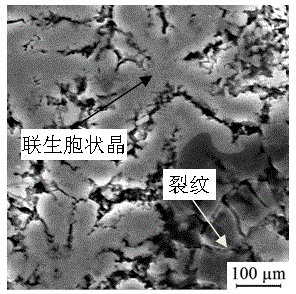

[0044] (4) Using cross-flow multimode CO 2 The composite coating was obtained by cladding NiCrAl powder and TiC powder on the aluminum alloy plate sample with a laser. The laser power was 4.0 kW, the scanning speed was 400 mm / min, the NiCrAl powder feeding rate was 0.55 g / s, and the TiC powder feeding rate was 0.1 g / s (the TiC c...

Embodiment 3

[0049] (1) Cut the aluminum alloy plate into a laser cladding sample, and perform shot blasting on the cladding surface of the aluminum alloy plate sample;

[0050] (2) Use acetone and alcohol to remove oxides, impurities and oil stains on the surface of cladding samples;

[0051] (3) Dry NiCrAl powder and TiC powder at 100°C for 6 hours to obtain pretreated NiCrAl powder and TiC powder, wherein the powder particle size of NiCrAl powder and TiC are both 100 nm, and NiCrAl powder is made of 100 nm Ni, Cr , Al powder mixed, the mass percentage of Cr in the NiCrAl powder is 18%, the mass percentage of Al is 8%, and the mass percentage of Ni is 74%;

[0052] (4) Using cross-flow multimode CO 2 The composite coating was obtained by cladding NiCrAl powder and TiC powder on the aluminum alloy plate sample with a laser. The laser power was 4.2 kW, the scanning speed was 380 mm / min, the NiCrAl powder feeding rate was 0.6 g / s, and the TiC powder feeding rate was 0.26 g / s (the TiC cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com