Benzene-free and ketone-free modified acrylate resin and preparation method thereof

A technology of acrylate and polyhydroxy acrylate, which is applied in the field of polymer chemistry and can solve problems such as harmful to health, failure to meet anti-adhesion performance, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

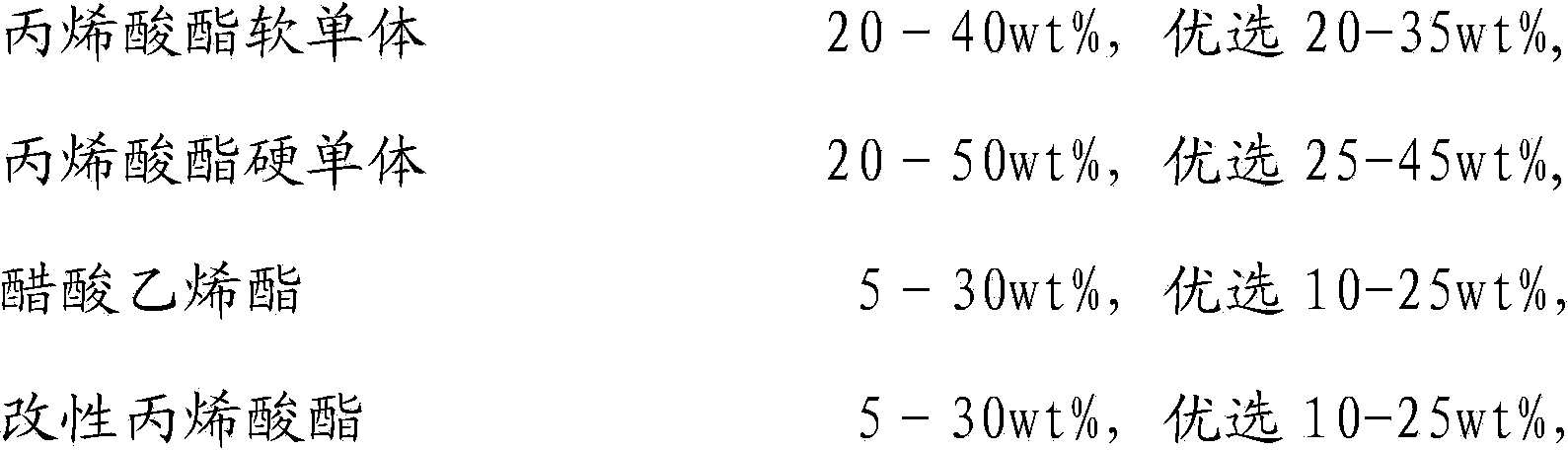

Method used

Image

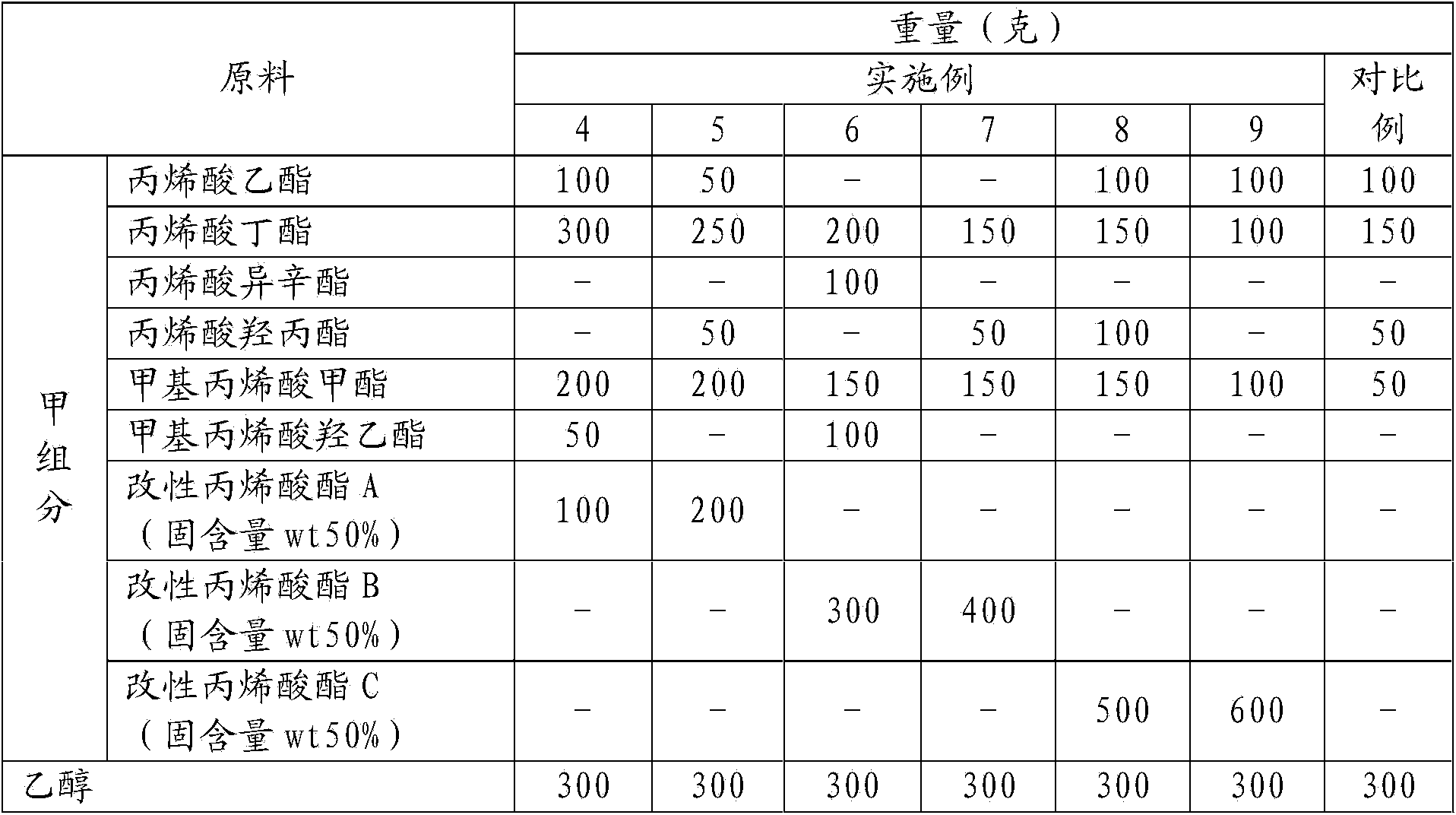

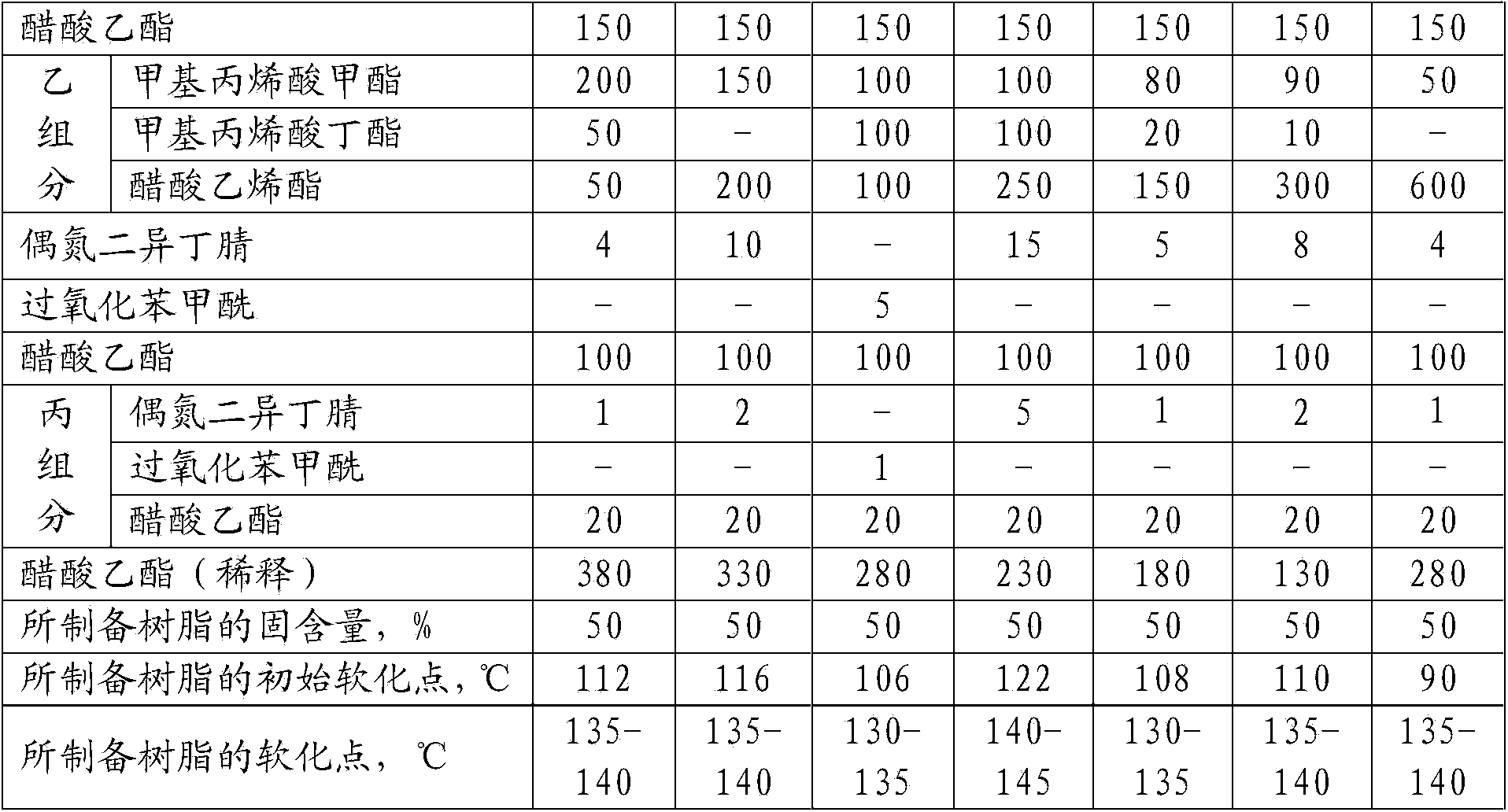

Examples

Embodiment 1

[0081] Embodiment 1 Preparation of modified acrylate A

[0082] The first step: take by weighing respectively the bisphenol A epoxy resin (0.7mol epoxy group) of 132 gram epoxy value 0.53eq / 100g, 151.4 gram acrylic acid (2.1mol carboxyl, mol ratio is epoxy group: carboxyl=1 : 3), 150 grams of ethyl acetate, add in the reactor that stirrer, reflux condenser and heating temperature control are housed, react at 70~90 ℃ for 5 hours, add 134 grams of ethyl acetate to dilute, make monomer content is a 50% solution of polyhydroxy acrylate I.

[0083] Step 2: Weigh 111.2 grams (1mol NCO) of isophorone diisocyanate (IPDI) and 30 grams of ethyl acetate solvent respectively, and add to the reactor equipped with stirring device, reflux condenser, heating control temperature and dropping device In the process, slowly add 18.4 grams (0.4mol hydroxy) ethanol, 0.1 grams of dibutyltin dilaurate catalyst, and 20 grams of ethyl acetate mixture by dropwise addition, and finish the dropwise addit...

Embodiment 2

[0085] Embodiment 2 Preparation of modified acrylate B

[0086] The first step: take by weighing 100 grams of 1,4 butanediol diglycidyl ether (0.7mol epoxy group) and 101 grams of acrylic acid (1.40mol carboxyl group) with an epoxy value of 0.7eq / 100g respectively, and the molar ratio is epoxy group : carboxyl group=1: 2), 100 gram n-propyl acetates, add in the reactor that stirrer, reflux condenser and heating temperature control are housed, react 4 hours at 90~100 ℃, add 101 gram n-propyl acetates to dilute , to prepare a polyhydroxy acrylate solution II with a monomer content of 50%.

[0087] The second step: Weigh 111.2 grams (1mol NCO) of isophorone diisocyanate (IPDI) and 30 grams of n-propyl acetate solvent respectively, and add a reaction reaction equipped with a stirring device, a reflux condenser, a heating control temperature and a dropping device In the container, slowly add 51 grams (0.5mol of hydroxyl) isopropanol and 0.1 gram of dibutyltin dilaurate catalyst, 2...

Embodiment 3

[0090] Example 3 Preparation of modified acrylate C

[0091] The first step: take by weighing 100 grams of neopentyl glycol diglycidyl ether (0.65mol epoxy group) and 140 grams of methacrylic acid (1.63mol carboxyl group) with an epoxy value of 0.65eq / 100g respectively, and the molar ratio is epoxy group : carboxyl=1: 2.5), 100 gram butyl acetates, add in the reactor that stirrer, reflux condenser and heating temperature control are housed, react 3 hours at 100~120 ℃, add 140 gram n-propyl acetates to dilute, A polyhydroxyacrylate solution III with a monomer content of 50% was prepared.

[0092]Second step: take 84.1 grams (1mol NCO) 1,6-hexamethylene diisocyanate (HDI) and 30 grams of ethyl acetate solvent respectively, add stirring device, reflux condenser, heating temperature control and dropping device In the reactor, slowly add 27.6 gram (0.6mol hydroxy) ethanol and 0.1 gram of dibutyltin dilaurate catalyst, 20 gram of ethyl acetate mixtures by dropwise addition, finish ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com