Graphite Paper Barium Titanate/Polyimide Integrated Composite Film Capacitor

A technology of polyimide and composite film, which is applied in the field of energy storage, can solve the problems of not being able to achieve the advantages of organic plastic film thickness, restricting the application of new capacitors, and difficult large-area preparation, so as to reduce production costs, energy consumption and low cost , The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

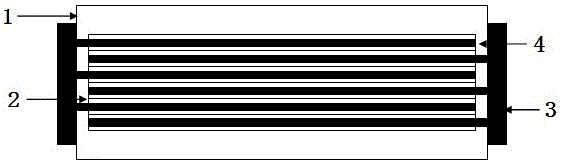

[0027] In this embodiment, an integrated composite film capacitor containing a monolithic double-layer dielectric layer is selected.

[0028] Concrete preparation method is as follows:

[0029] The first step: pretreatment process: first add barium titanate powder into absolute ethanol with a mass fraction of 95%, ultrasonically disperse for 1 hour, centrifuge, wash, dry, and set aside; press the cut graphite paper electrode Press it until it is flat, wipe it with absolute ethanol and dry it for later use.

[0030] Step 2: Preparation of coating film: under nitrogen protection, add 5.008 g of 4,4'-diaminodiphenyl ether (4,4'-ODA) to 100 mL of N,N-dimethylacetamide (DMAc), after stirring to dissolve completely, add 5.453 g of pyromellitic dianhydride (PMDA), and stir vigorously for 4 hours to prepare a polyamic acid solution with a solid content of 10%, then take 30 g of the above solution, and add 12.63 g The barium titanate after ultrasonic dispersion was stirred for 24 hou...

Embodiment 2

[0036] In this example, an integrated composite film capacitor containing two layers of three dielectric layers is selected.

[0037] Concrete preparation method is as follows:

[0038] The first step: pretreatment process: first add barium titanate powder into absolute ethanol with a mass fraction of 95%, ultrasonically disperse for 1 hour, centrifuge, wash, dry, and set aside; press the cut graphite paper electrode Press it until it is flat, wipe it with absolute ethanol and dry it for later use.

[0039]Step 2: Preparation of coating film: under nitrogen protection, add 5.008 g of 4,4'-diaminodiphenyl ether (4,4'-ODA) to 100 mL of N,N-dimethylacetamide (DMAc), after stirring to dissolve completely, add 5.453 g of pyromellitic dianhydride (PMDA), and stir vigorously for 4 hours to prepare a polyamic acid solution with a solid content of 10%, then take 30 g of the above solution, and add 12.63 g The barium titanate after ultrasonic dispersion was stirred for 24 hours to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com