Anhydrous graphene oxide cooling liquid for engine and preparation method thereof

A graphene and water cooling technology, applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the problems of engine overheating performance, easy cavitation, cooling system corrosion, etc., to ease the lateral temperature gradient, improve thermal conductivity, The effect of strong thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 45Kg of ethylene glycol and 48Kg of propylene glycol and stir evenly; then add 1.2Kg of silicone defoamer into it, heat and stir fully with a magnetic stirrer for about 1 hour until uniform; then add 0.5kg of tolyltriazole, 0.5kg of Benzotriazole, 0.8kg sebacic acid, 0.3kg citric acid, 0.8kg sodium hydroxide, 0.7kg phosphoric acid, 0.7kg ammonium molybdate, heated to 178°C under reflux and stirred until completely dissolved; finally added 1.5kg of graphene oxide is ultrasonically dissolved in the obtained mixed solution by an ultrasonic instrument with a frequency of 60KHZ until it is completely dissolved, and then the finished anhydrous cooling liquid of the present invention is obtained, with a freezing point of -50°C and a boiling point of 186°C.

Embodiment 2

[0023] Weigh 45Kg of ethylene glycol and 47Kg of propylene glycol and stir evenly; then add 1.2Kg of organosilicon defoamer into it, and stir fully with a magnetic stirrer for about 1 hour until uniform; then add 0.5kg of tolyltriazole, 0.5kg of benzene Triazole, 0.8kg sebacic acid, 0.6kg citric acid, 0.8kg sodium hydroxide, 0.7kg phosphoric acid, 0.7kg ammonium molybdate, heated to 180°C under reflux and stirred until completely dissolved; finally added 2.2 kg graphene oxide, ultrasonically dissolve the obtained mixed solution by an ultrasonic instrument with a frequency of 60KHZ until it is completely dissolved, and then the finished anhydrous cooling liquid of the present invention is obtained, with a freezing point of -50°C and a boiling point of 187.4°C.

Embodiment 3

[0025] Weigh 45Kg of ethylene glycol and 45Kg of propylene glycol and stir evenly; then add 1.2Kg of organosilicon defoamer to it, and stir fully with a magnetic stirrer for about 1 hour until uniform; then add 1.5kg of tolyltriazole, 0.5kg of benzene Triazole, 0.8kg sebacic acid, 0.8kg citric acid, 0.8kg sodium hydroxide, 0.7kg phosphoric acid, 0.7kg ammonium molybdate, heated to 183°C under reflux and stirred until completely dissolved; finally added 3kg Graphene oxide is ultrasonically dissolved in the obtained mixed solution by an ultrasonic instrument with a frequency of 60KHZ until it is completely dissolved, and the finished anhydrous cooling liquid of the present invention is obtained, with a freezing point of -50°C and a boiling point of 188.5°C.

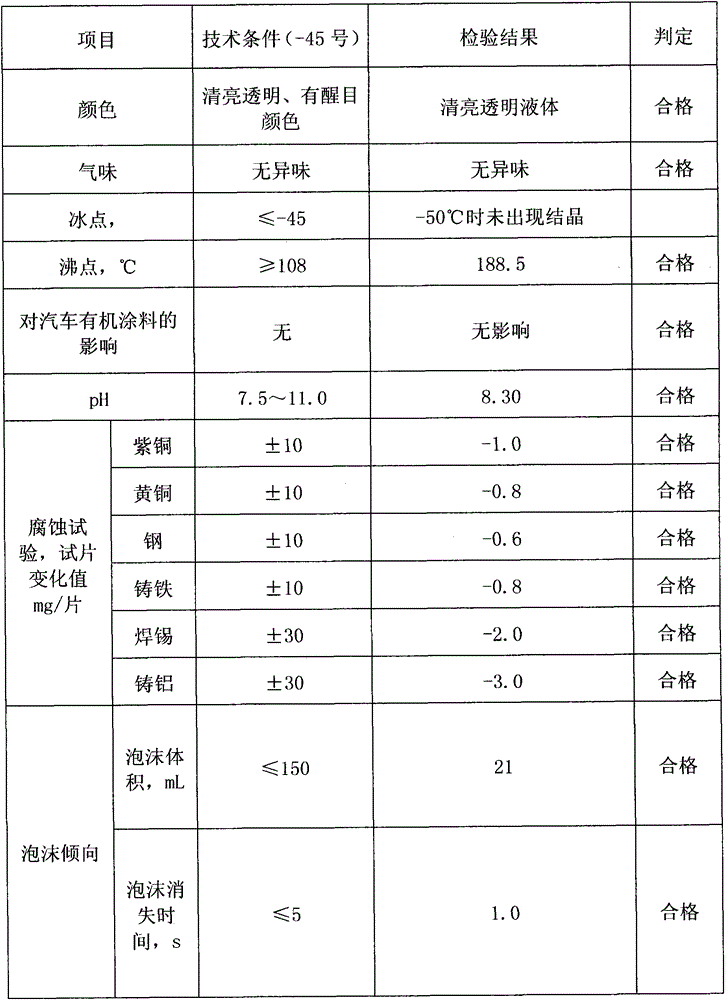

[0026] After the product of the present invention is sent to the Chinese People's Liberation Army Oil Plant and Oil Plant Equipment Inspection and Test Center for inspection, the inspection report is as follows, and part of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com