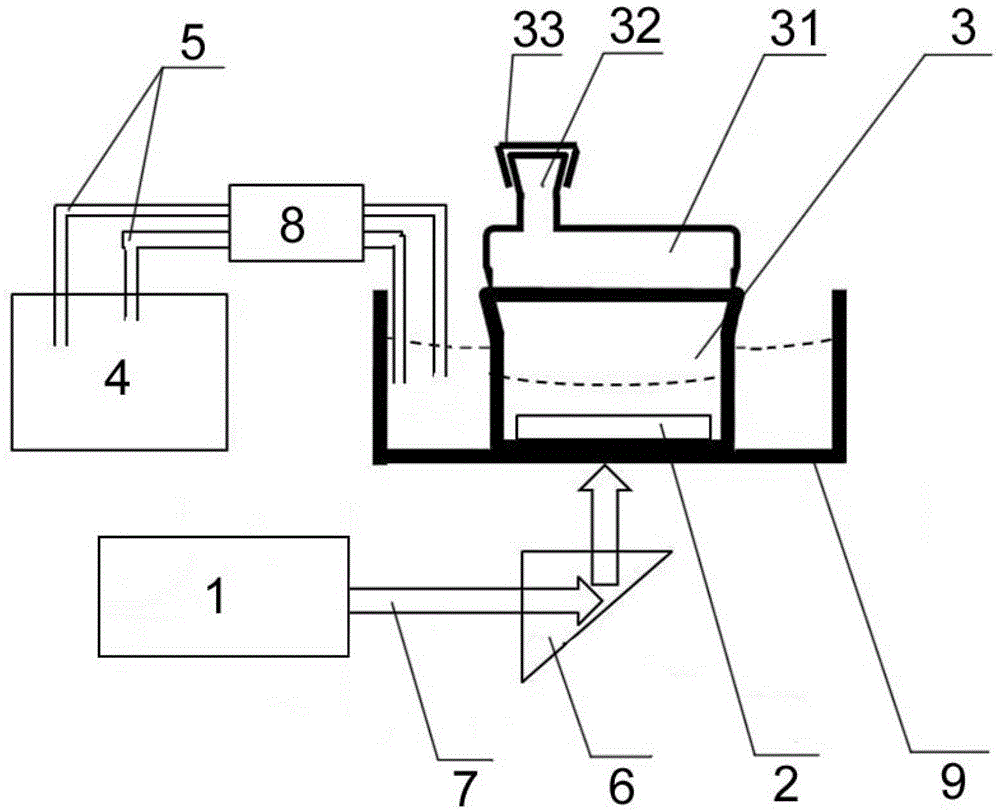

Device and method for photosensitizing the surface of a carrier to prepare metal nanomaterials

A technology of metal nano-carrier surface, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of unpublished literature reports of nano-metal materials, and achieve strong adhesion strength and controllability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

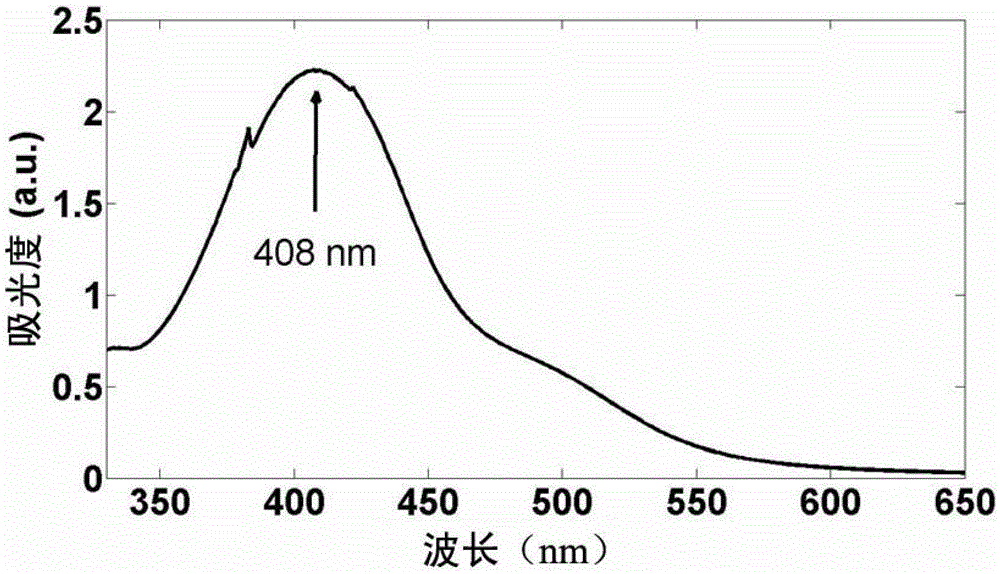

[0033] Utilize the device of the present invention to carry out the method for photosensitizing the base surface of a quartz plate to prepare a nano-silver material, comprising the following steps:

[0034] (1) Preparation of photosensitization reaction solution: Dissolve silver nitrate and benzophenone into ethanol to prepare a photosensitization reaction solution. The concentrations of silver nitrate and benzophenone in the solution are 10mmol / L and 4mmol / L, respectively;

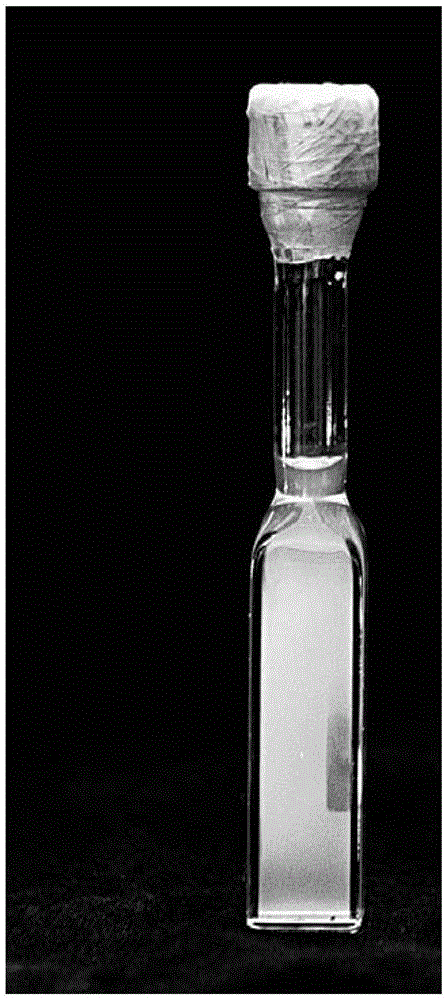

[0035] (2) The photosensitization reaction solution obtained in step (1) is poured into a quartz photoreaction cell, the carrier is a quartz plate base, and the size is 20mm in length, 4mm in width, and 1mm in thickness; put the carrier into the photosensitization reaction solution and immerse it, cover Put the cork on the bottle, and then seal the ventilation hole on the cork with a sealing film; place the photoreaction cell lying down so that one side wall faces down, and due to gravity, the base of the ...

Embodiment 2

[0040] Utilize the device of the present invention to carry out the method for preparing nano-copper material by photosensitization of the surface of the quartz plate base, its steps are different from Example 1 in that:

[0041] 1. Preparation of photosensitization reaction solution: Melt copper nitrate and benzophenone into ethanol to prepare photosensitization reaction solution. The concentrations of silver nitrate and benzophenone in the solution are 5mmol / L and 3mmol / L respectively;

[0042] 2. The carrier is a quartz plate base, with a size of 20mm in length, 4mm in width and 1mm in thickness;

[0043] 3. Set the water temperature in the temperature control tank to 10°C, the light source is ultraviolet continuous light, the wavelength range is 250-450nm, the electric power is 1-25000W, and the beam irradiation time is 30min;

[0044] The nano-silver material loaded on the prepared carrier is ultrasonically cleaned, and no nano-silver material falls off after 30 minutes, ...

Embodiment 3

[0046] Utilize the device of the present invention to carry out the method for photosensitizing the base surface of a quartz plate to prepare a nano-gold material, the steps are different from Example 1 in that:

[0047] 1. Preparation of photosensitization reaction solution: dissolve gold chlorate, benzophenone and polyvinylpyrrolidone (stabilizer) into ethanol to prepare photosensitization reaction solution, in which gold chlorate, benzophenone and polyethylene The concentrations of pyrrolidone were 4mmol / L, 3mmol / L and 0.02mmol / L respectively;

[0048] 2. The carrier is porous silica particles with a pore size of about 1nm;

[0049] 3. Set the water temperature in the temperature control tank to 10°C, the light source is ultraviolet continuous light, the wavelength range is 250-450nm, the electric power is 1-25000W, and the beam irradiation time is 20min;

[0050] Ultrasonic cleaning is performed on the prepared nano-gold material loaded on the carrier, and no nano-silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com