Mini-type test evaluation device for integral SCR denitration catalyst reaction performance test and application method thereof

A technology of denitration catalyst and reaction performance, applied in the field of catalysis, can solve the problems of metal atom migration, heat loss, reactor scrapping, etc., and achieve the effect of high operating temperature, lower working temperature and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

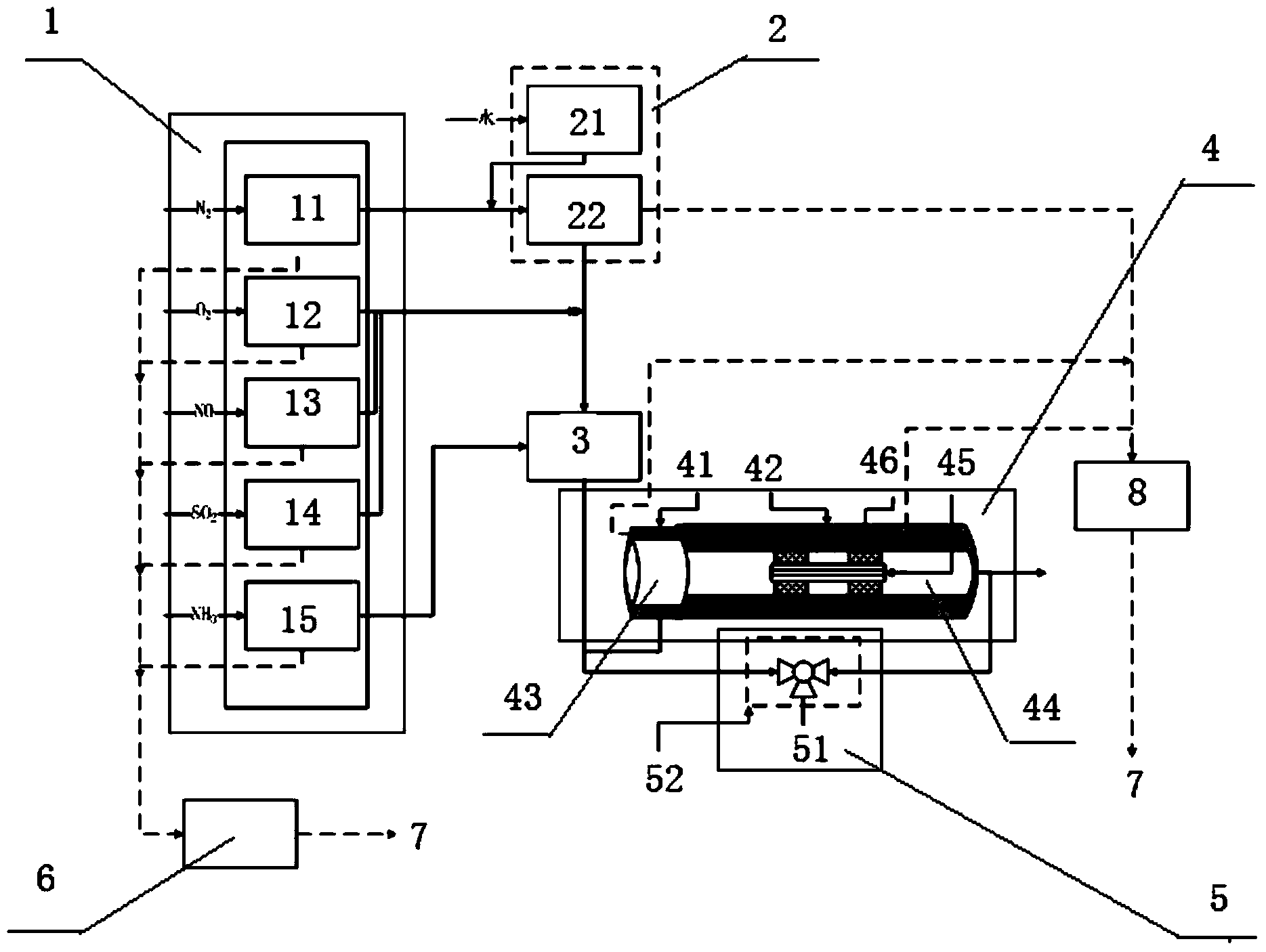

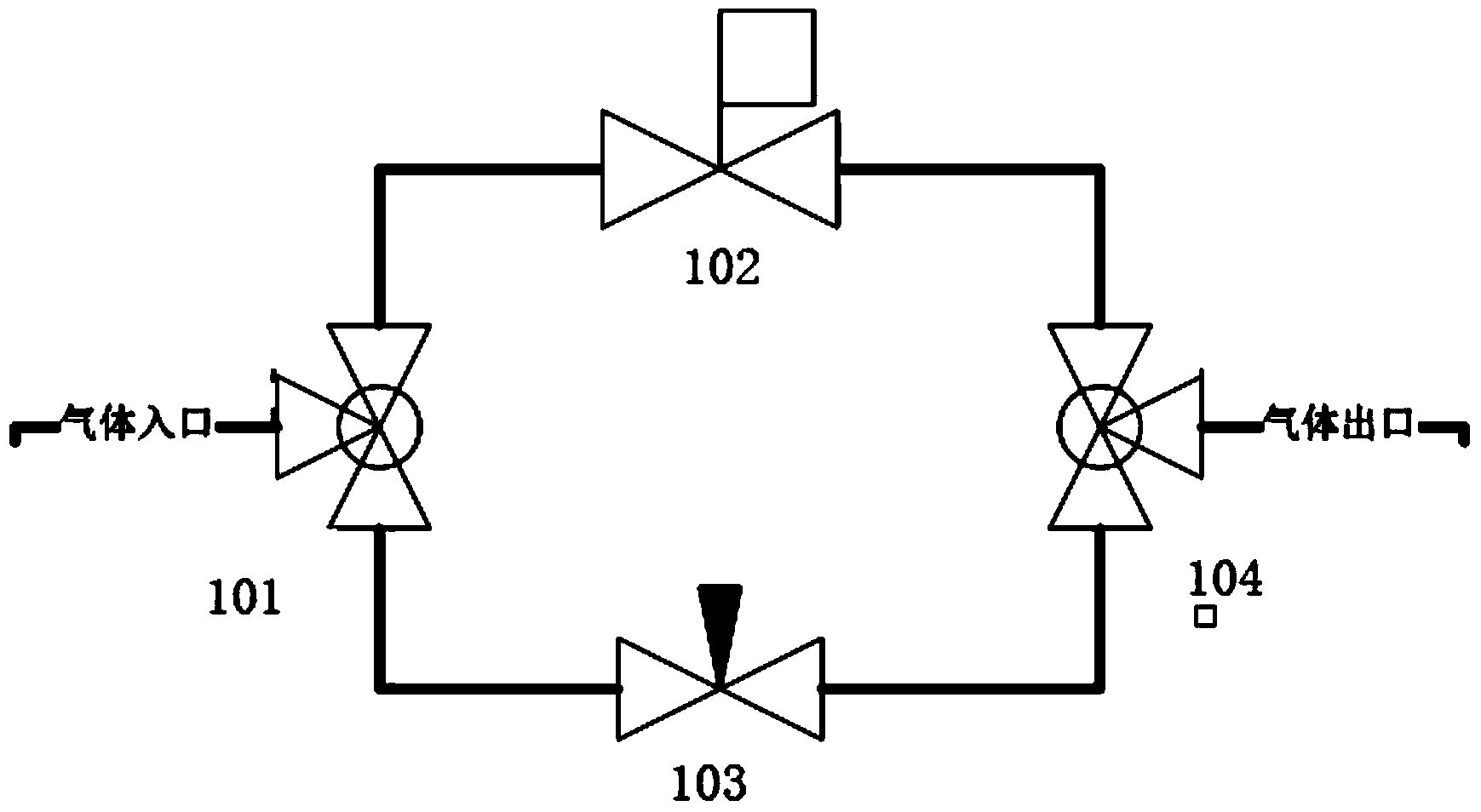

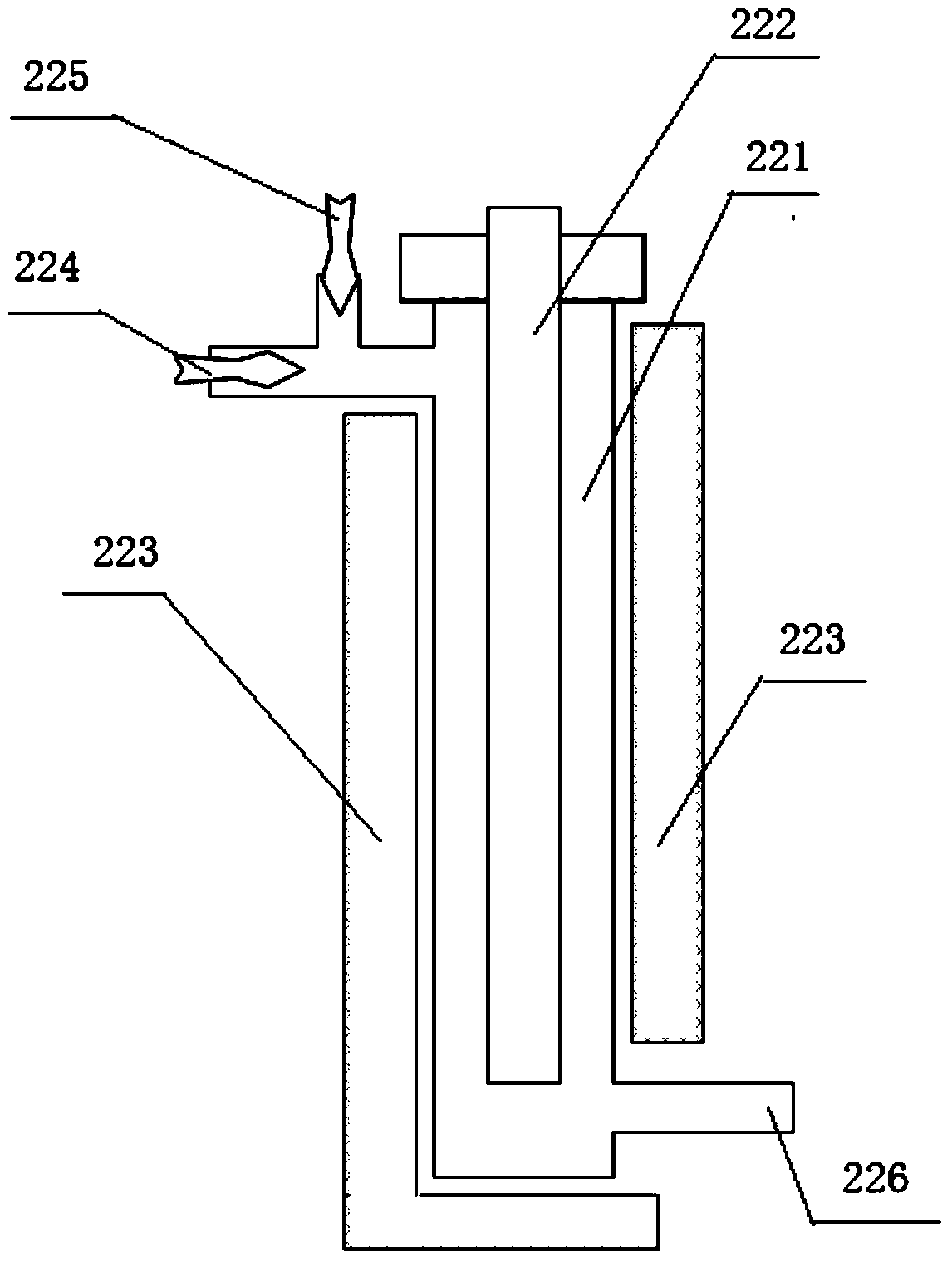

[0038] Such as Figure 1-6 As shown, a micro test and evaluation device used for testing the reaction performance of the overall SCR denitrification catalyst, the output end of the reaction gas sampling control device 1 is connected to the flow controller 6 by a wire, and the output end of the water vapor generation device 2 is connected by a pipeline It is connected to the gas mixing device 3, and the output end of the reaction gas sampling control device 1 is connected to the steam generating device 2 and the gas mixing device 3 by pipelines respectively; the output end of the gas mixing device 3 is connected to the preheating-reaction connected to device 4, preheating-reactor 4 and steam generating device 2 are connected to temperature controller 8 by wires; preheating-inlet and outlet ports of reactor 4 are connected to reaction gas sampling-analyzing device 5; flow controller 6 and the temperature controller 8 are respectively connected to the display device 7 by wires. ...

Embodiment 2

[0051] Select 086 batches of honeycomb catalyst products manufactured by the applicant, and cut them into experimental samples with a length of 300 mm and a cross-sectional size of 25×25 mm. The axial part of the sample is wrapped with an appropriate amount of inert insulation material and then placed in the Figure 5 Inside the catalyst filling tube shown, the upper end of the sample is 400 mm from the upper end of the gas preheating tube. Insert a temperature measuring thermocouple inside the sample, cover the open end of the gas preheating tube with a quartz glass cover, and seal it through a frosted flat flange.

[0052] Such as figure 1 As shown, the reaction gas sampling control device 1 , the steam generating device 2 , the gas mixing device 3 , the preheating-reactor 4 and the reaction gas sampling-analysis device 5 are connected. The temperature and flow automatic control instruments corresponding to each point in the system are centrally controlled through the HIM ...

Embodiment 3

[0059] Most of the state and parameter settings of the device are the same as in Example 2, the difference is that in order to make the catalyst bed temperature reach 500°C, the heating temperature of the reaction furnace surrounded by the upper end of the preheating-reactor 4 is 530°C, so that the gas in the gas preheating section The temperature is 510° C., and the temperature of the catalyst bed is kept at 500° C. by controlling the heating temperature of the reaction furnace surrounded by the lower end of the reactor to be 510° C. The reactor showed no signs of damage.

[0060] In this embodiment, the steam outlet temperature is 500°C, the gas preheating section temperature is 510°C, and the catalyst bed temperature is 500°C. The concentration of nitric oxide at the reactor inlet is 179ppm, ammonia 180ppm, oxygen 2.01%, sulfur dioxide 100ppm; the concentration of nitric oxide at the reactor outlet is 15ppm, ammonia 0ppm, oxygen 1.70%, sulfur dioxide 59ppm, and the conversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com