Preparation method of magnetic carbon nanotube with polydopamine-modified surface

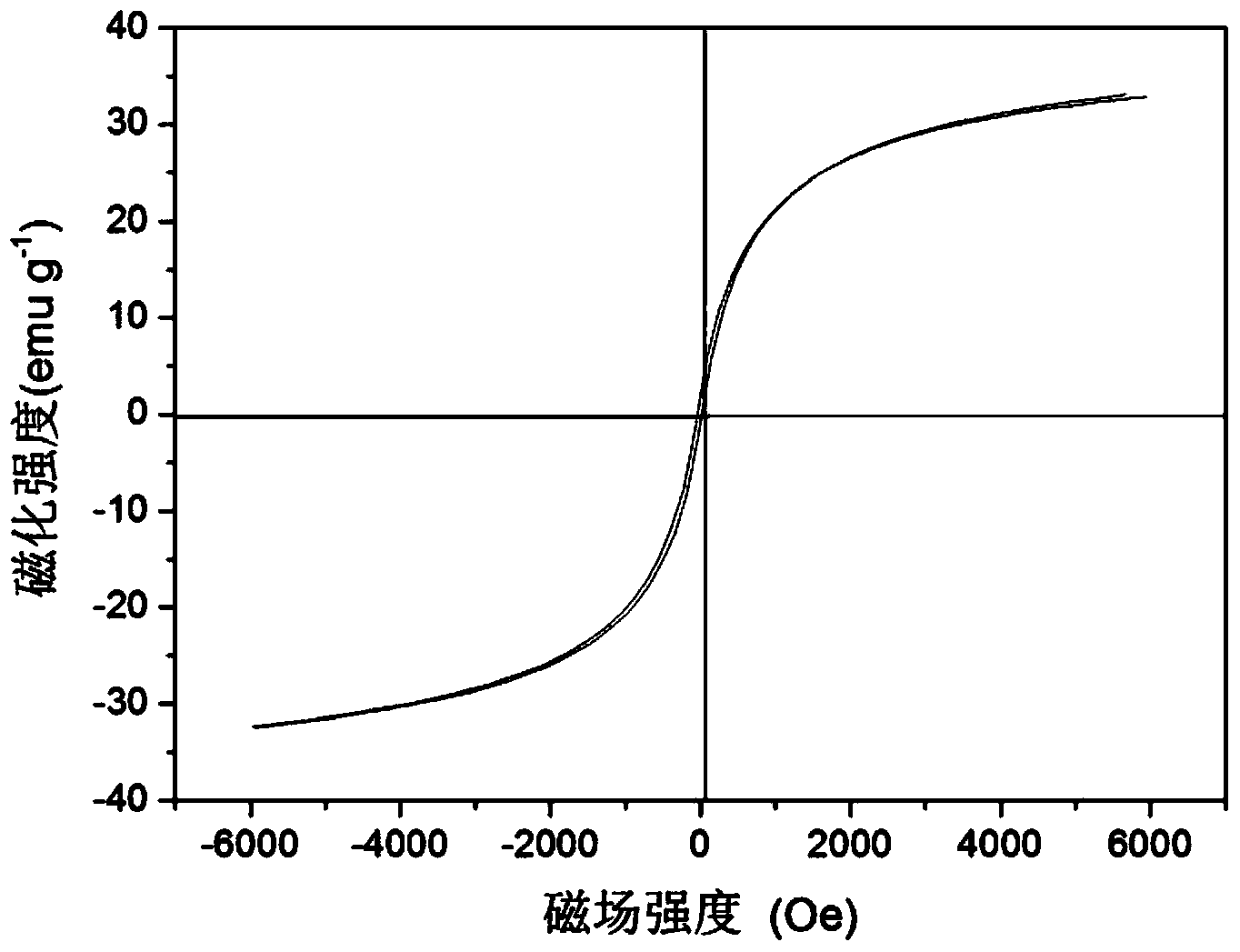

A technology of magnetic carbon nanotubes and polydopamine, which is applied in the field of nanomaterials, can solve the problems of difficult surface modification, reduced magnetism, and easy oxidation of nanomagnetic particles, and achieve the effect of rapid separation and enrichment and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

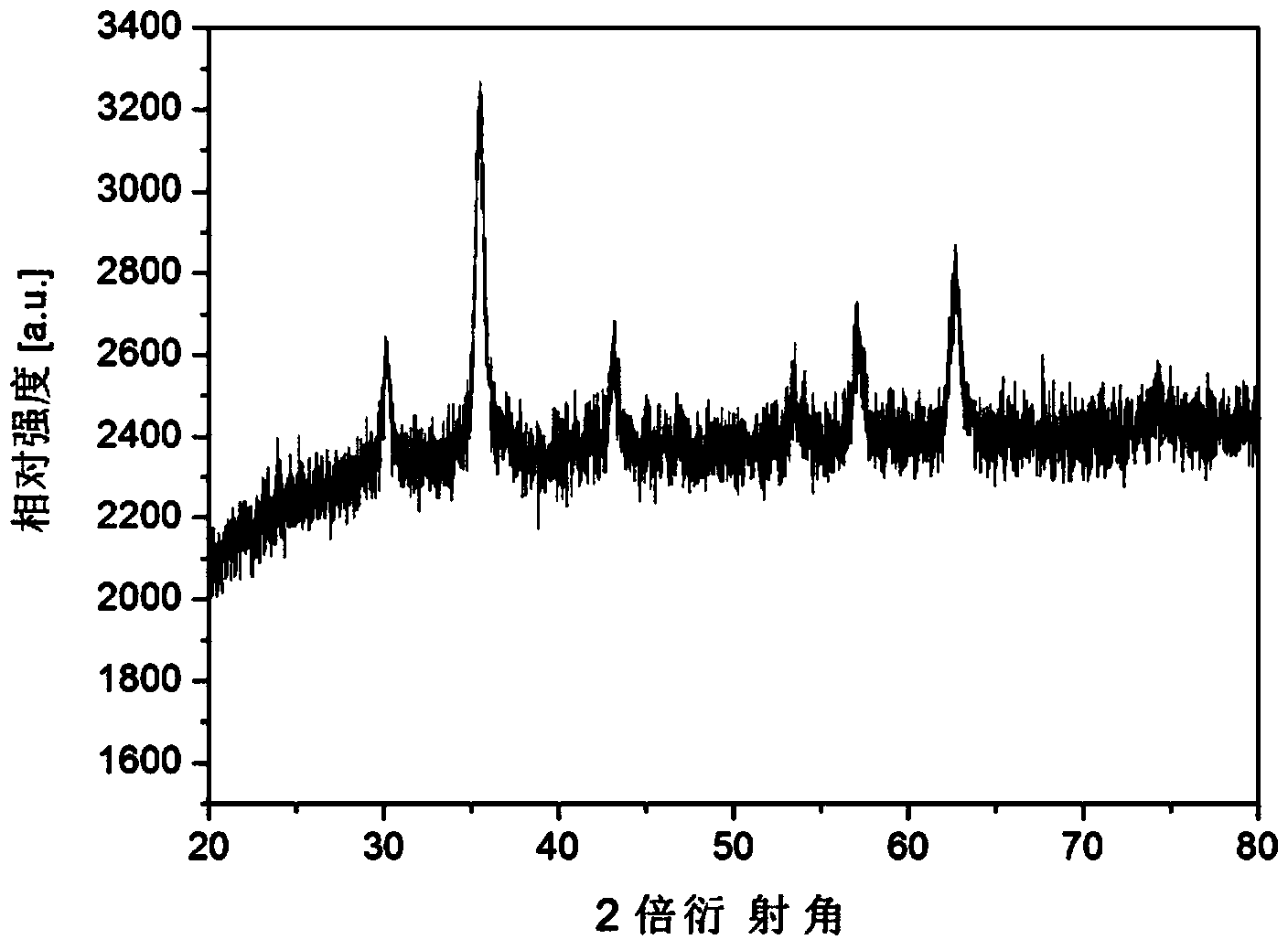

[0030] (a) Weigh FeCl respectively 3 ·6H 2 O0.5g and 2.0g of anhydrous sodium acetate were dissolved in 7mL of ethylene glycol and 13mL of diethylene glycol and mixed evenly, placed in a high-pressure reactor, the reaction temperature was 190°C, the reaction time was 12h, and the reaction pressure was 1-6Mpa. After the reaction is finished, cool down to room temperature naturally. In the presence of an external magnetic field, separate the solid compound in the reaction kettle, wash with deionized water and absolute ethanol for 3-6 times, remove the residual organic solvent in the product, and dry it in vacuum. to obtain magnetic nanoparticles.

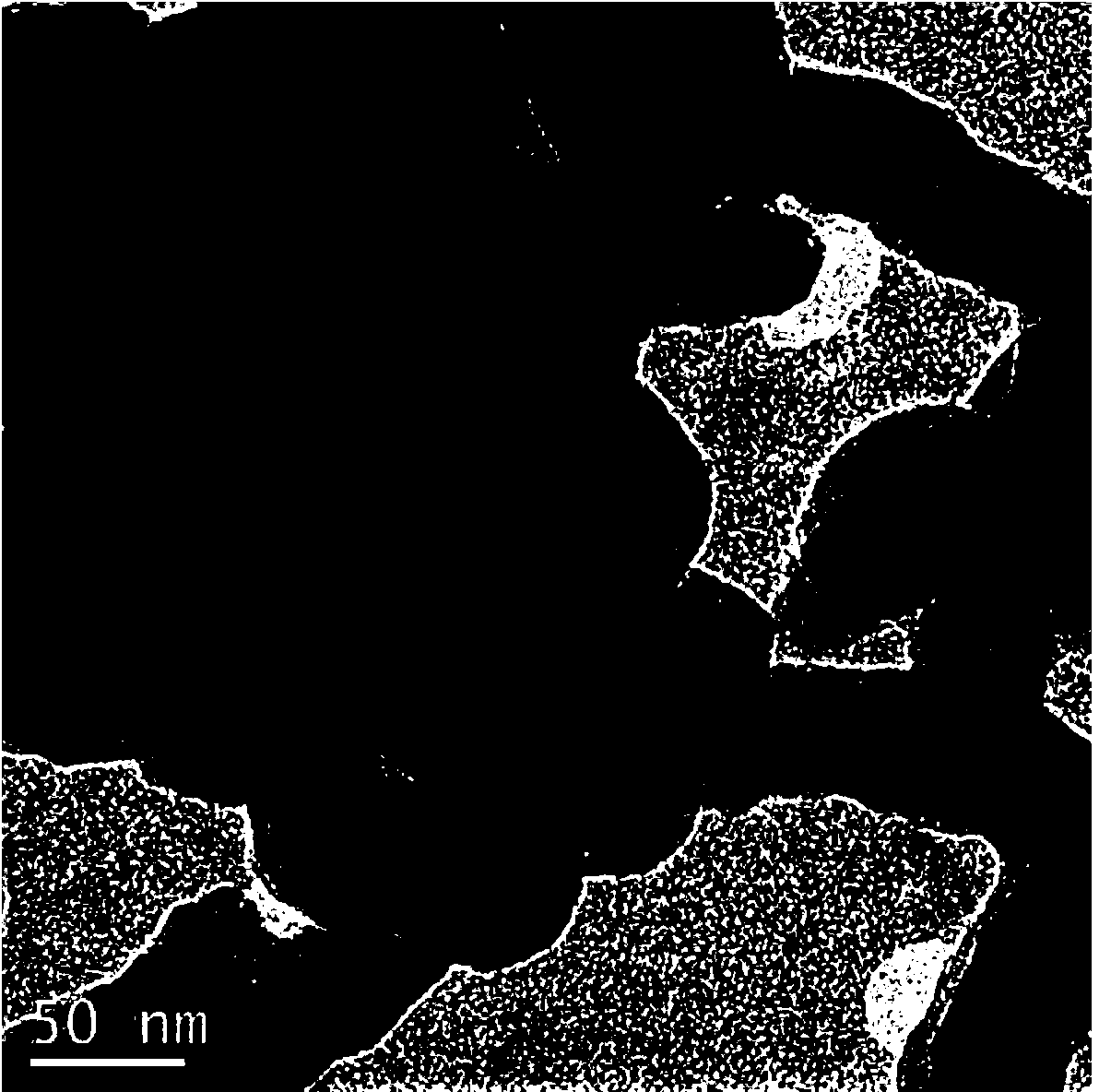

[0031] (b) Weigh 0.8g of magnetic nanoparticles and 0.2g of carbon nanotubes and dissolve them in 50mL of ethylene glycol, sonicate at 30°C for 3h, and then 400r min -1 Stir the mixture at a high speed for 30 min to obtain a homogeneous mixture.

[0032] (c) Transfer the mixed solution obtained in step (b) to a sealed stainless ste...

Embodiment 2

[0035] (a) Weigh FeCl respectively 3 ·6H 2 O0.5g and 2.0g of anhydrous sodium acetate were dissolved in 10mL of ethylene glycol and 10mL of diethylene glycol and mixed evenly, placed in a high-pressure reactor, the reaction temperature was 210°C, the reaction time was 6h, and the reaction pressure was 1-6Mpa. After the reaction is finished, cool down to room temperature naturally. In the presence of an external magnetic field, separate the solid compound in the reaction kettle, wash with deionized water and absolute ethanol for 3-6 times, remove the residual organic solvent in the product, and dry it in vacuum. to obtain magnetic nanoparticles.

[0036] (b) Weigh 0.8g of magnetic nanoparticles and 0.2g of carbon nanotubes and dissolve them in 40mL of ethylene glycol, sonicate at 40°C for 2h, and then 250r min -1 Stir the mixture at a high speed for 60 min to obtain a homogeneous mixture.

[0037] (c) Transfer the solution obtained in step (b) to a sealed stainless steel aut...

Embodiment 3

[0040] (a) Weigh FeCl respectively 3 ·6H 2O1.0g and 2.0g of anhydrous sodium acetate were dissolved in 10mL of ethylene glycol and 10mL of diethylene glycol, mixed evenly, placed in a high-pressure reactor, the reaction temperature was 200°C, the reaction time was 12h, and the reaction pressure was 1-6Mpa. After the reaction is finished, cool down to room temperature naturally. In the presence of an external magnetic field, separate the solid compound in the reaction kettle, wash with deionized water and absolute ethanol for 3-6 times, remove the residual organic solvent in the product, and dry it in vacuum. to obtain magnetic nanoparticles.

[0041] (b) Weigh 0.6g of magnetic nanoparticles and 0.2g of carbon nanotubes and dissolve them in 30mL of ethylene glycol, sonicate at 40°C for 3h, and then use 300r min -1 Stir the mixture at a high speed for 60 min to obtain a homogeneous mixture.

[0042] (c) Transfer the solution obtained in step (b) to a sealed stainless steel au...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com